From Failure to Revival: Edison’s Forgotten Nickel-Iron Battery Returns that Charges in Seconds and Lasts for Decades

Key Takeaways

- A research collaboration co-led by UCLA has revived Thomas Edison’s nickel-iron battery.

- The researchers used proteins to guide the growth of extremely small nickel and iron clusters.

- These clusters were embedded in ultrathin carbon sheets to form highly efficient electrodes.

- The battery can recharge in seconds and has remained functional after more than 12,000 full charge/discharge cycles.

- The fabrication process is simple, cost-effective, and uses widely available materials.

- The technology could be used for long-lasting energy storage in solar farms, backup power systems.

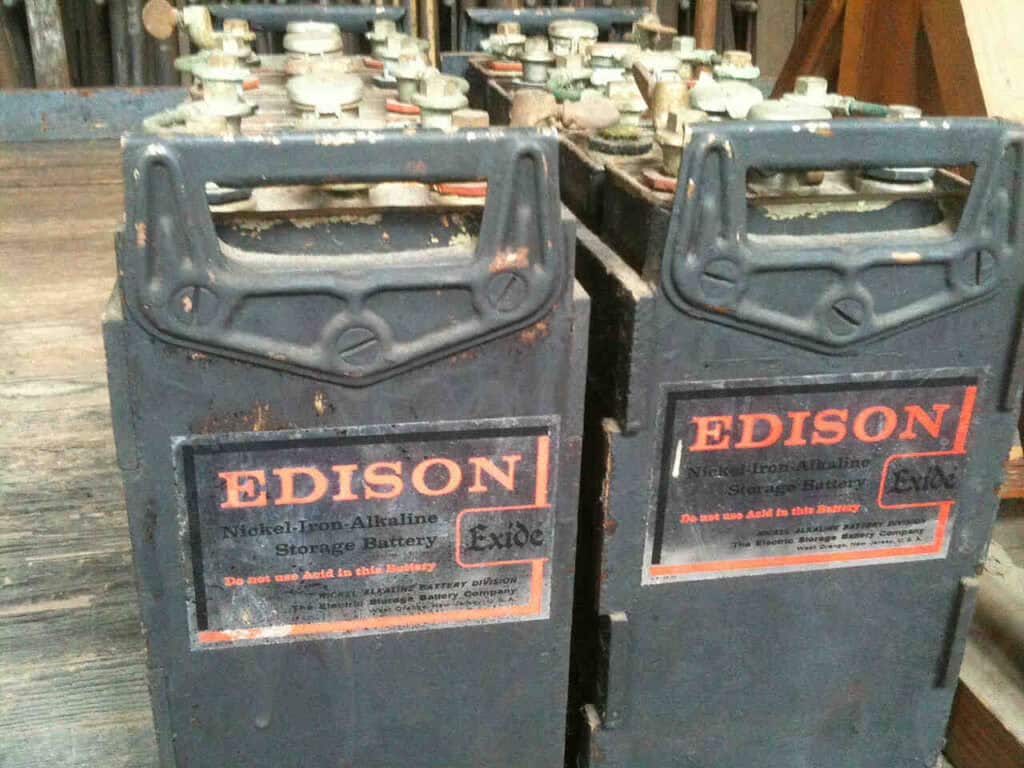

Thomas Edison’s Nickel Iron Battery

Over a century ago, Thomas Edison wasn’t just tinkering with light bulbs. He was on a mission to build a battery tough enough to power electric cars and heavy machinery.

At the time the lead-acid auto battery, Edison’s own creation was costly and could only go about 30 miles on a single charge. Edison saw a better way. He believed the nickel-iron battery or NiFe could be the future. It promised a 100-mile range a long lifespan and a recharge time of just seven hours which was fast for the era.

The NiFe battery wasn’t sleek or light but it was built like a tank. Overcharge it? No problem. Freeze it? Still works. Drop it or leave it unused for years? It would keep going. Some of Edison’s original batteries are reportedly still running today in museums and old industrial sites.

So, if they were this good, why aren’t they everywhere?

Why Edison’s Battery Fell Behind

The problem was not reliability. It was performance.

Edison’s battery was bulky. It charged slowly. It did not store as much energy as newer designs. It also released hydrogen gas during use, which reduced efficiency and created safety concerns. As gasoline engines improved and the auto industry expanded, speed and convenience took priority. The nickel iron battery gradually faded into the background.

For decades, it remained a niche technology, mostly used in off grid solar systems and heavy industrial setups where long life mattered more than compact size.

Now, that might be changing.

UCLA Gives It a 21st Century Glow Up

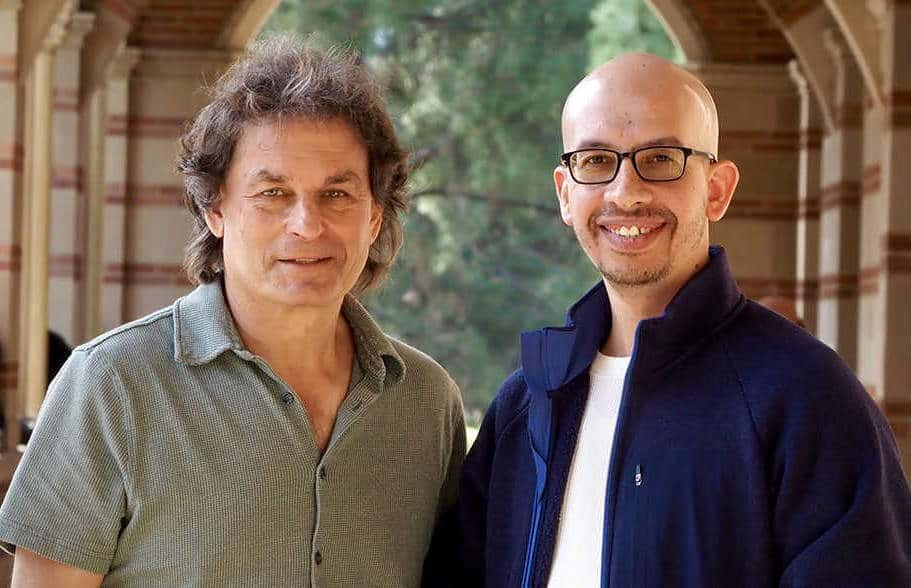

Fast forward to today, an international team co-led by UCLA has taken the old nickel-iron battery and given it a major upgrade. Key figures include Ric Kaner a leading expert in nanomaterials and Maher El-Kady, who has spent years working on energy storage along with contributions from Bruce Dunn and Sarah Tolbert from earlier research.

This new version uses ideas borrowed from biology to fix the battery’s old problems. The researchers took proteins that would normally go to waste from beef production and used them as tiny guides. These proteins help nickel and iron atoms form extremely small clusters, just a few nanometers wide.

The clusters are placed onto very thin sheets of porous carbon, similar to graphene. This gives the electrodes a huge surface area so nearly every atom can take part in storing energy unlike traditional batteries where only the surface layer is active.

What the New Version Can Do

The results are impressive. The prototype can charge in just minutes, delivers strong power and has gone through more than 12,000 full charge and discharge cycles in lab tests. That is the same as using it every day for more than 30 years with hardly any loss in performance.

The process is simple and inexpensive. “We are just mixing common ingredients, applying gentle heat, and letting the battery form naturally,” said Maher El-Kady, assistant researcher at UCLA. “It’s surprisingly straightforward, but it works incredibly well.”

Inspired by Nature

The researchers drew inspiration from nature. Animals grow bones and shellfish build shells using proteins that guide minerals into strong, lightweight structures.

They applied the same idea to batteries. Proteins from beef byproducts helped grow tiny clusters of nickel for positive electrodes and iron for negative ones. The folds in the proteins kept the clusters under five nanometers, so small that 10,000 to 20,000 could fit across a human hair. Some clusters were even single atoms.

The proteins were mixed with graphene oxide, a single-atom-thick carbon material. Superheating and high-temperature baking turned the proteins into carbon, removed oxygen from the graphene, and embedded the metal clusters. The result was a carbon aerogel that is 99% air.

This airy structure allows energy to move quickly in and out of the battery, solving the slow-charging problem of older NiFe designs. Smaller clusters also provide more surface area, which speeds up chemical reactions and charging.

“The way nature arranges materials matters as much as the materials themselves,” says Ric Kaner, UCLA professor and co-author. “Proteins help place atoms in the right spots, making structures strong yet flexible.”

Surface Area: The Battery’s Secret Weapon

The magic behind the new NiFe battery lies in its surface area. The smaller the metal clusters, the more surface is exposed for chemical reactions. Almost every atom in the clusters participates in storing and releasing energy, which allows the battery to charge and discharge much faster than traditional designs.

El-Kady notes: “As you shrink the particles down to nanoclusters, the surface area explodes. This is why the battery works so efficiently, it’s like every atom is pulling its weight.”

Why This Matters Now

The world is desperate for better ways to store renewable energy. Renewable energy sources like solar and wind are expanding quickly, but they do not always produce electricity when people need it. That is where energy storage becomes critical.

Batteries bridge that gap. Lithium ion dominate the market today but the supply chain is shaky prices swing wildly and mining those materials comes with real environmental and human costs.

A revived nickel iron battery could be a solid alternative especially for big stationary uses like home backup systems community microgrids or utility scale storage where size and weight aren’t as critical as cost safety and longevity.

The UCLA group has already shown prototypes that charge way faster than the originals some in under 15 minutes while holding onto that legendary toughness.

Its not going to replace lithium in your phone or electric car tomorrow but for keeping the lights on when the sun isn’t shining or the wind isn’t blowing it could be a game changer particularly in places where people can’t afford fancy imported batteries.

Still Early, But Promising

Don’t get too carried away yet. Lab success does not automatically translate into large scale production. Scaling manufacturing, reducing costs further, and testing performance in real world environments are the next steps.

Energy density remains lower than lithium, which limits its use in portable devices.

Still, the bigger picture is compelling.

More than 120 years after Edison imagined it powering the future, his battery design is getting a second chance. This time, it is backed by nanoscience and bio inspired engineering.

It may not power the electric cars he once envisioned. But it could help keep the lights on in a renewable energy world that needs durable and affordable storage more than ever.

Related Posts:

- US Firm Unveils Small Nuclear Reactor to Power 300K Homes

- A Nuclear Nano-Diamond Battery, that Lasts For 28,000 Years

- Betavolt Developed a Nuclear Battery with a 50-Year Lifespan

- Qurmit – 95% Recyclable Fireproof Battery with 20 Years of Lifespan

- US Firms Plan Nuclear Battery Nickel-63 with 50-Year Lifespan to Counter China

- Finland Successfully Tests Wireless Electricity Transmission

- Japan Introduces Magnetic Levitation Car Technology – The End of Engines and Batteries

- Norway Sets Up World’s First Wireless EV Charging Road

- Poland Builds Solar-Powered Bike Lane That Glows Blue in the Dark

- Japan Uses Electrically Heated Sidewalks to Prevent Snow Accumulation on Roadways

- Wave, Wind, and Solar Hybrid Energy Raft Could Power 1,000 Homes a Day

- Colorful and Transparent Solar Panel to Replace Your Windows

- Swedish Scientists Develop Liquid that Stores Solar Energy for 20 Years

Finland Successfully Tests Wireless Electricity Transmission

Finland Successfully Tests Wireless Electricity Transmission US Scientists Break Kirchhoff’s 165-Year-Old Physics Law

US Scientists Break Kirchhoff’s 165-Year-Old Physics Law When and Why Did the U.S. Transition from 110V to 120V Supply?

When and Why Did the U.S. Transition from 110V to 120V Supply? Is It Dangerous to Carry a Battery in an Elevator?

Is It Dangerous to Carry a Battery in an Elevator? Is It Possible to Get Electrocuted by an Electric Vehicle?

Is It Possible to Get Electrocuted by an Electric Vehicle? What is the Correct Wire Size for 100A Breaker and Load?

What is the Correct Wire Size for 100A Breaker and Load?