Which is Better for Electrical Connections, Wire Nuts or Wago Wire Connectors?

When it comes to electrical wiring, the quality of a connection matters just as much as the wire itself. A loose or poorly made joint can lead to overheating, voltage drop, nuisance tripping, or even fire hazards. Two of the most commonly used wire-joining methods are wire nuts and WAGO connector. Among electricians and electrical enthusiasts, one debate never seems to end: WAGO connectors vs wire nuts.

Both are designed to join electrical conductors safely, but they do it in very different ways. Let’s break down what each one is, how they work, and which option is better for modern electrical installations.

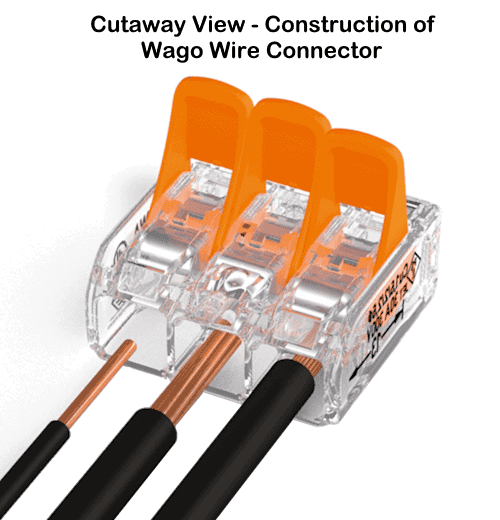

What is a WAGO Connector?

A WAGO connector (also known as Lever-nut) is a spring-clamp wire connector developed by WAGO, a German electrical components manufacturer (now a generic term for the technology). Wagos are commonly used in residential, commercial, and industrial electrical installation. They are used for joining wires in the box for lighting fixtures, sockets, ceiling fans, general sub-circuits and final-sub-circuits. The most popular versions are lever-type connectors (such as the WAGO 221, 222 series) and push-in connectors (e.g., 773 series).

Instead of twisting wires together, WAGO spring-loaded connectors use an internal spring mechanism to hold the conductor firmly in place. With lever-type WAGOs, you simply lift the lever, insert the wire, and close it.

Wagos are available in 2, 3, 5, and more port options for splicing multiple wires, including connecting short wires after device removal.

Good to Know:

- Wagos are commonly used in UK, EU, AUS/NZ and other IEC following countries.

- Wagos are mostly used for stranded wire, but they can also be used safely for connecting different wire types e.g. solid, stranded or flexible etc.

Why Electricians Like WAGO Connectors

- Fast and tool-free installation

- Works with solid, stranded, and flexible wires

- Reusable (especially lever types)

- Transparent housing for easy inspection

- Maintains constant pressure on the conductor

This design helps reduce installation errors and improves long-term reliability.

When Should You Use WAGO Connectors?

- Stranded or mixed wire types

- Fast installations and clean wiring especially for overhead or tight work

- Tight or crowded junction boxes (when space is limited)

- Frequent future modifications or troubleshooting

- Vibration-prone environments

How to use Them?

Using WAGOs for joining wires is simple, as they are made for it.

In wago connectors, the conductor is inserted into a spring-loaded clamp. In lever-type WAGOs, lifting the lever opens the clamp; closing it secures the wire. The spring maintains constant pressure on the conductor. Here is how to do it step-wise.

- Strip the wire to the recommended length (check the connector’s strip gauge).

- Lift the connector’s lever.

- Insert the stripped wire fully into the port.

- Flip the lever back down to secure the connection.

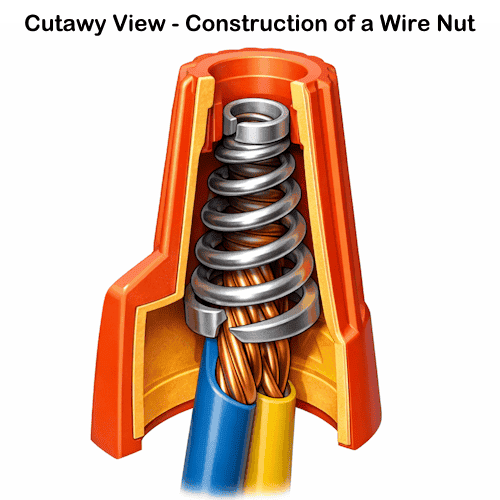

What is a Wire Nut?

A wire nut, also called a twist-on wire connector, is the traditional and most widely used method of joining wires, especially in North America. It’s a plastic cap with an internal metal spring that grips the conductors as the nut is twisted on.

Wire nuts are code-compliant devices used to splice and insulate two or more electrical wires in residential and commercial circuits such as lighting, celling fans, outlets/receptacles, and electrical box connected to the branch circuit.

Wire nuts are available in different types and color-coded by size (gray, blue, orange, yellow) to handle wire ranges from #18 AWG to #10 AWG. Some are waterproof for outdoor use The material used for shell is thermoplastic, and even specialized ceramic versions exist for high-temperature applications. They are mostly used for low-voltage residential/commercial wiring and generally not recommended for high-amperage, large motor leads.

Good to Know:

- Wire-nuts are commonly used in US, Canada and similar codes following countries i.e. NEC/CEC.

- Wire nuts are are mostly used for joining solid solid wire.

Why Wire Nuts are Still Popular

- Very low cost

- Easily available everywhere

- Proven history in residential wiring

- No special tools required

When installed correctly, wire nuts can provide a solid and safe electrical connection.

When Are Wire Nuts a Better Choice?

- Solid copper conductors

- permanent connections

- Simple residential wiring

- Budget-sensitive projects

- Installations done by experienced electricians

How to Use Wire-nuts?

While some manufacturers suggest pre-twisting wires with pliers is unnecessary, many electricians do so to ensure a stronger, more reliable mechanical connection before applying the nut.

To use a wire nut, the wires must be stripped, twisted together, and then secured with the connector. In short, they are tightened by hand until the internal spring tightens around the conductors to hold them together.

Comparison: WAGO vs Wire Nut

- Ease of Installation

- WAGO: Very easy and fast. No twisting required. Ideal for tight spaces and repetitive work.

- Wire Nut: Requires proper wire stripping, twisting, and tightening. Installation quality depends heavily on the installer’s skill.

✔ – Winner: WAGO

- Connection Reliability

- WAGO: Spring clamp provides constant pressure, even with thermal expansion and contraction.

- Wire Nut: Connection quality depends on how well the wires are twisted. Poor twisting can cause loose connections over time.

✔ – Winner: WAGO

- Compatibility with Wire Types

- WAGO: Lever-type connectors accept solid, stranded, and flexible wires easily.

- Wire Nut: Works best with solid conductors. Stranded wires can be problematic if not twisted correctly.

✔ – Winner: WAGO

- Reusability

- WAGO: Lever connectors are reusable; wires can be removed and reinserted without damage.

- Wire Nut: Typically single-use. Reusing can weaken the internal spring and compromise safety.

✔ – Winner: WAGO

- Space and Box Fill

- WAGO: Compact and organized, especially useful in crowded junction boxes.

- Wire Nut: Bulkier when multiple conductors are twisted together.

✔ – Winner: WAGO

- Inspection and Troubleshooting

- WAGO: Transparent housing allows visual confirmation of proper wire insertion.

- Wire Nut: No visual confirmation once installed.

✔ – Winner: WAGO

- Cost

- WAGO: More expensive per connector.

- Wire Nut: Very inexpensive and cost-effective for large projects.

✔ – Winner: Wire Nut

- Code Compliance

- Both WAGO connectors and wire nuts are UL-listed, IEC and NEC-compliant when used according to manufacturer instructions.

- Acceptance may vary by region and inspector familiarity.

✔ – Winner: Tie (when properly approved)

Common Myths and Misconceptions

- Myth: WAGOs are not safe:

False. Certified WAGO connectors are extensively tested and widely used in Europe and North America.

- Myth: Wire nuts are always better because they’re traditional

Fact: Longevity depends on correct installation, not age of the technology.

- Myth: Wire nuts are always stronger

Fact: Strength depends on installation quality.

- Myth: WAGO is only for low current

Fact: Many WAGO connectors are rated up to 32A or more.

- Myth: WAGO is not durable

Fact: Industrial control panels widely use WAGO.

Which One is Better?

From a modern electrical standpoint, WAGO connectors offer better consistency, fast installation, and reliability. They reduce human error and make electrical work cleaner and more organized.

That said, wire nuts still have their place. They are affordable, familiar, and reliable when installed correctly.

In short:

- Best overall choice: WAGO connectors

- Best budget option: Wire nuts

In addition:

Choose WAGO: For residential, remodeling, DIY projects, connecting stranded to solid wire, and tight electrical boxes.

Choose Wire Nuts: For industrial, high-vibration environments, or when cost-effectiveness for thousands of connections is priority.

The “better” option depends on your wiring type, environment, application type, budget and installer kit, but for today’s electrical work, WAGO connectors clearly represent the future.

Related Posts:

- Wire Nuts and Connectors Color Codes – Wire and Gauge Sizes

- Types of Electrical Wires and Cables

- Different Types of Wiring Systems and Methods of Electrical Wiring

- Automotive Blade-Type Fuse Color Codes with Ampere Ratings

- Electrical Wiring Color Codes for AC & DC – NEC & IEC

- Resistor Color Codes

- Capacitor Color Codes

- Inductor Color Codes

- ABYC Cable & Wire Color Codes for Yacht, Boat & Marine Wiring

- MV & HV Cable Termination to Equipment & Joints

- Electric Stress Control in Cable, Joints & Terminations

- American Wire Gauge (AWG&) Chart & Wire Size & Ampacity Table

How to Wire a Tandem Breaker for 120V and 240V Circuits

How to Wire a Tandem Breaker for 120V and 240V Circuits How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel