Why is the Use of Solid Wire Prohibited on Moving Components Such as Ships and Vehicles?

Solid wire is generally not recommended for use in ships, vehicles, or other applications involving movement because it is prone to breaking or developing fatigue due to flexing, vibration, and temperature fluctuations. Its rigid nature makes it unsuitable for environments where constant motion or vibration is present. Instead, stranded wire is preferred in such cases, as it is more flexible and can withstand bending and movement without breaking.

Related Post: Why are US Homes Wired Using Solid Wire rather than Stranded Wire?

Why is Solid Wire Forbidden in Vehicles and Ships?

The use of solid wire is forbidden on ships, vehicles, and moving parts due to the following several mechanical and safety-related reasons.

Flexibility and Metal Fatigue Due to Vibration

Solid wire is stiff and inflexible. It cannot tolerate repeated movement or vibration. They are tend to crack or snap due to metal fatigue from constant bending or flexing. As a result, it can lead to open circuits, Intermittent faults and electrical fires hazards.

Ships and vehicles constantly experience vibrations from engines, rough terrain, road bumps (in car), waves motion (in ship), turbulence (in aircraft), etc. Solid wire, being a single, rigid conductor, is susceptible to metal fatigue when subjected to repeated bending or vibration. This can cause the wire to harden, become brittle, and eventually break at stress points, particularly near terminal connections or bends.

In moving parts (like robotic arms, machinery, or even door wiring in a car), the wire needs to flex repeatedly. Solid wire cannot handle this without breaking. A single bend over and over will eventually snap a solid conductor.

Difficulty in Routing and Installation:

Solid wire is stiff and less flexible, making it difficult to route through tight spaces, around corners, or into complex geometries common in vehicles and ships. Stranded wire, with its many smaller strands, is much more pliable and easier to snake through confined spaces.

Troubleshooting & Maintenance

A broken solid wire can be extremely difficult to locate, especially if the break occurs inside the insulation. This leads to frustrating troubleshooting and potential system failures.

On the other hand, when even a few strands break in stranded wire, the connection still largely functions, though its current-carrying capacity might be slightly reduced. A complete break in a solid wire means a total loss of connection.

Safety Hazard

A broken solid wire can lead to intermittent connections, arcing, sparking overheating, short circuit and potentially fires. The is case is extremely dangerous, especially in fuel-rich or flammable environments like ships or vehicles.

- Related Post: Stranded Wire vs Solid Wire. Which One is Best and Why?

Why is Stranded Conductor Preferred in Vehicle, Machines and Moving Devices?

Stranded wire (made of multiple smaller wires twisted together) is designed for motion because of its flexible and can withstand motion and vibration with longer mechanical life in dynamic environments.

Stranded wire is preferred for these applications because they are highly flexible and able to withstand repeated bending, flexing, and vibration without breaking. The multiple strands distribute stress, making the wire more resistant to metal fatigue and physical damage. Moreover, flexibility of stranded conductor makes it much simpler to route and install in complex and tight spaces. In addition, even if a few strands break, the overall connection often remains intact, preventing complete circuit failure.

For these reasons, industry standards (like ABYC E-11 for marine applications) explicitly require the use of stranded wire for electrical systems in boats, vehicles, and other applications involving movement and vibration.

Automotive And Maritime Standards For Wire Type

Maritime and automotive electrical codes (e.g., ABYC, ABS, DNV, NEC, ISO, SAE) specify the use of stranded wire only for all dynamic or mobile applications.

- IEC 60092-352 – Choice and Installation of Cables for Ships: Clause 5.2.3: “Cables used in areas subject to vibration or movement shall be of the flexible (stranded) type.”

- ABS (American Bureau of Shipping) and ABYC E-11: Cables must be marine-grade, stranded, and flexible to endure the ship’s motion and environment.

- DNV (Det Norske Veritas) explicitly requires stranded conductors in all shipboard systems exposed to vibration or motion.

- SAE J1128 requires stranded copper conductors to handle vibration, flexing, and thermal cycling.

- ISO 6722-1:2021 – Specifies only stranded wire for road vehicles due to mechanical stress and flexibility needs.

- UL 758 (Appliance Wiring Material): For wiring used in vehicles and machinery, flexible (stranded) wire is required when motion is present.

Related Posts:

- ABYC Cable & Wire Color Codes for Yacht, Boat & Marine Wiring

- Electrical Wiring Color Codes for AC & DC – NEC & IEC

- Is It Possible to Get Electrocuted by an Electric Vehicle?

- Why Can’t a 12V Car Battery Electrocute You?

- Why is the Grounding Wire Bare and Not Insulated?

- Why is the Standard Voltage in the US 120V/240V and 230V in the EU?

- Why is the Standard Frequency 60 Hz in the US & 50 Hz in the EU?

- Why Does Japan Use Both 50Hz and 60Hz in Its Power System?

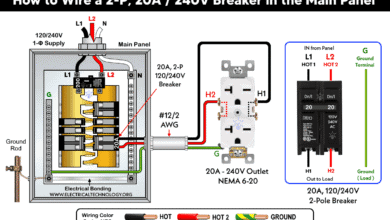

How to Wire a Tandem Breaker for 120V and 240V Circuits

How to Wire a Tandem Breaker for 120V and 240V Circuits How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel