Difference Between Equipment Grounding Conductor (EGC) and Grounding Electrode Conductor (GEC)

Electrical grounding is the process of connecting all exposed metallic parts of an electrical system to the earth. This is done as a safety measure to protect both equipment and people from fault currents, such as electric shocks caused by short circuits, and to prevent hazardous fires.

The grounding system, also known as electrical earthing, consists of multiple components, including the EGC, GEC grounding electrodes, etc. Two essential conductors in a grounding system are the Equipment Grounding Conductor (EGC) and the Grounding Electrode Conductor (GEC). While the terms used for these critical parts feels similar, they differ in their functions, sizing methods, and installation locations.

What is Equipment Grounding Conductor (EGC)?

An Equipment Grounding Conductor (EGC) is a conductor used to connect non-current-carrying metal parts of electrical equipment to the to the grounded conductor (neutral) or grounding electrode conductor (GEC). Its primary function is to provide a low-impedance path for fault currents to flow safely to the ground. In the event of a ground fault (e.g., a short circuit to a metal enclosure), the EGC triggers the overcurrent protection devices (OCPDs) like circuit breakers or fuses to de-energize the circuit. This protects personnel from electric shock and prevents equipment damage.

During a ground fault or short circuit, the EGC facilitates the operation of overcurrent protection devices (OCPDs) by allowing sufficient current flow to trip the breaker and disconnect the circuit. Hence, It ensures that metallic enclosures, raceways, and equipment frames remain at ground potential to prevent electric shock hazards.

The EGC is typically a copper or aluminum conductor, either insulated or bare, and is installed within the same raceway or cable as the circuit conductors. Moreover, metal conduit (EMT, RMC) may also serve as an EGC. It connects equipment enclosures, raceways, and other metallic components to the grounding bus in the service panel. The key functions of EGC is bonding metal parts of electrical equipment, providing a fault-current return path to the source, and clearing faults quickly by activating protective devices.

The Equipment Grounding Conductor (EGC) can be bare, covered, or insulated, and is typically identified by green color or green with yellow stripes, as per NEC requirements. In receptacles and cords, the EGC connects to a green-colored or hexagon-shaped terminal marked “G,” “GR,” “GRN,” “GRND,” or the ⏚ symbol, following NEC 250.126 and 406.9(B). The EGC must be properly identified along its accessible length or at termination points using green coloring, markings, or adhesive labels in compliance with NEC 250.119(A), 250.119(B)(2), 250.119(C)(1,2,3), 250.62, and 250.64.

Good to Know:

The Equipment Grounding Conductor (EGC), also known as the “grounding conductor” or “safety ground”, is used to provide bonding between electrical equipment. A green, green with yellow strap or bare conductor is used for grounding conductor. EGC is attached to the metal parts of equipment which provides a conductive path for the fault current to flow back to the source in the event of short circuit or ground faults.

In the United States (according to the NEC), it is called the Equipment Grounding Conductor (EGC), whereas in BS 7671 and IEC-compliant countries, it is referred to as the Earth Continuity Conductor. Although the terminology differs, the function and purpose remain the same.

How to Size EGC?

The sizing of an EGC is governed by the NEC Article 250.122 and Table 250.122. This section provides minimum sizes of EGC based on the rating of the overcurrent protective device (OCPD) in the circuit.

The EGC size depends on the ampere rating of the circuit breaker or fuse protecting the circuit, not the size of the circuit conductors. NEC Table 250.122 provides the minimum size for EGCs. For example:

- For a 15A circuit, the minimum EGC size is 14 AWG copper or 12 AWG aluminum.

- For a 20A circuit, the minimum EGC size is 12 AWG copper or 10 AWG aluminum.

- For a 100A circuit, the minimum EGC size is 8 AWG copper or 6 AWG aluminum.

The sizes of copper EGCs are smaller than aluminum due to copper’s higher conductivity as shown in EGC sizing table. That’s why copper is preferred and recommended over aluminum conductors.

If circuit conductors are upsized to account for voltage drop in the long run, the EGC must also be proportionally increased to maintain fault-clearing capability (NEC 250.122(B)). In addition, bonding conductors in feeders and branch circuits are sized similarly. For motor circuits or other specific applications, additional rules may apply based on the circuit, such as high-fault current conditions, equipment bonding, and adjustments for parallel conductors 250.122(F).

Where to Use EGC?

EGCs are used in virtually all electrical circuits to ensure safety. Common applications include:

- Branch Circuits: EGCs are installed in branch circuits to ground outlets and receptacles, lighting fixtures, and appliances.

- Feeders: Between distribution panels and subpanels.

- Service equipment downstream from the main bonding jumper.

- Equipment Enclosures: Metal enclosures of electrical equipment, such as panelboards, junction boxes, raceways, bonding metallic housing and electrical machines such as motor frames and transformer cases, are connected to an EGC.

- Raceways and Cables: EGCs are included in metallic conduits, cable assemblies (e.g., NM cable), or metal-clad (MC) cables to ground metallic raceways or armor.

- Portable Equipment: Tools or appliances with metal cases often rely on EGCs in their power cords to prevent shock hazards.

EGCs are not used for connecting to ground rods or electrodes directly. It is always required wherever metallic components could become energized due to a fault.

What is Grounding Electrode Conductor (GEC)?

A Grounding Electrode Conductor (GEC) is a conductor that connects the grounding electrode system (e.g., ground rods, metal water pipes, or building steel) to the grounded (neutral) conductor at the service equipment or the main disconnect grounding bus.

Its primary purpose is to establish a low-impedance path between the electrical system and the earth to stabilize the system voltage under normal conditions and providing a reference for fault currents (caused by overvoltage i.e. lightning strikes, line surges, or accidental contact with higher-voltage systems) to dissipate into the ground. – NEC 250.4(A)(1).

The GEC ensures that the electrical system is bonded to earth, reducing the risk of voltage differences between the system and the ground, which could lead to shock hazards or equipment damage during lightning strikes or high-voltage surges.

Good to Know:

- Unlike the EGC, the GEC does not carry fault current under normal operation.

- Grounding Electrode Conductor (GEC) in NEC is known as the Earthing Lead in BS 7671 and IEC-compliant countries.

How to Size GEC?

The sizing of a GEC is determined using the NEC Article 250.66 and Table 250.66, which bases the size on the largest ungrounded service-entrance conductor or or equivalent area for parallel conductors.

The GEC size depends on the size of the ungrounded (phase) conductors entering the service based on GEC sizing table. For example:

- For 1 or 1/0 AWG copper or 2/0 or 3/0 AWG aluminum / copper-clad aluminum ungrounded conductor, the required GEC size is 6 AWG copper or 4 AWG aluminum / copper-clad aluminum.

- For a 2/0 or 3/0 AWG copper service conductor, a minimum 4 AWG copper GEC is required.

- For a 350 to 600 kcmil copper or over 500 kcmil through 900 kcmil aluminum / copper-clad aluminum service conductor, the minimum GEC size is 1/0 AWG copper or 3/0 AWG aluminum / copper-clad aluminum.

The GEC size may vary depending on the grounding electrode. For instance, a smaller GEC (e.g., 6 AWG copper) is allowed for a single ground rod, but larger sizes are required for metal water pipes or building steel (NEC 250.66(A)-(C)).

For certain environment, copper, aluminum, or copper-clad aluminum can be used as GEC with proper termination methods to prevent corrosion. Except the chosen martials used for GECs, they must be continuous or spliced using irreversible methods (e.g., exothermic welding) to ensure reliability.

Good to Know:

- GEC is a conductor which connects the grounding busbar in the main panel or service equipment / disconnect to the grounding electrode (ground rod) stuck into the ground earth.

- GEC sizing does not need to match the full ampacity of the service conductors.

- If connecting multiple electrodes, bonding jumpers must be at least as large as the GEC.

Where to Use GEC?

The GEC is used to establish a connection to the earth via grounding electrodes. Typical applications include:

- Service entrance panels and equipment: The GEC connects the main service panel’s grounding bus to the grounding electrode system (e.g., ground rods, concrete-encased electrodes, Ufer grounds, or metallic underground water pipes).

- Separately derived systems: GECs are used in systems like transformers neutral connection or generators to bond their neutral to the grounding electrode system.

- Lightning protection systems: GECs help dissipate lightning-induced surges by providing a path to earth.

Comparison Between EGC and GEC

The EGC and GEC can sometimes be confusing because both are grounding conductors, but they are used for different purposes. EGC (Equipment Grounding Conductor) and GEC (Grounding Electrode Conductor) are distinct but related components. An EGC connects the metal parts of equipment to the grounding system to provide a fault current path, while a GEC connects the electrical system to the earth via a grounding electrode.

Their sizing methods also differ. the EGC is sized based on the overcurrent protective device rating, following NEC Table 250.122, whereas the GEC is sized based on the size of the service entrance conductors, according to NEC Table 250.66.

The Equipment Grounding Conductor (EGC) must be connected to the neutral conductor at only one point to prevent ground loops. Connecting the EGC at multiple points can create unintended paths for objectionable current to flow through the GEC. This can lead to improper operation of GFCIs) and RCDs. On the other hand, the Grounding Electrode Conductor (GEC) is connected to a single grounding electrode in a dwelling unit when the grounding resistance is less than 25 ohms.

Unlike the EGC, the GEC is not part of equipment grounding but ensures system grounding integrity. GECs are typically installed at the main service disconnect or separately derived system, not in individual branch circuits like EGC.

The following table shows the key differences between ECG and GEC:

| Feature | Equipment Grounding Conductor (EGC) | Grounding Electrode Conductor (GEC) |

| Purpose | Provides a fault current path to trip the OCPDs (breaker or fuse) to protect equipment/personnel. | Connects the electrical system to earth for stabilization and lightning protection against surges. |

| Function | Equipment bonding and fault clearing for protection. | System grounding and overvoltage dissipation. |

| Sizing | NEC Table 250.122 (based on OCPD i.e. breaker rating). | NEC Table 250.66 (based on service entrance conductor size). |

| Location | Runs with circuit conductors to ground equipment enclosures and all applicable metallic parts. | Connects service entrance / equipment disconnect to grounding electrodes (e.g., ground rods). |

| Where Used | Throughout the electrical system: Branch circuits, feeders, equipment enclosures, raceways, and cables. | Between service equipment and grounding electrodes (earth ground) for shock and lightning protection. |

| Conductors Types | Bare or insulated copper/aluminum, conduit. | Bare or insulated copper, aluminum or copper-clade aluminum |

| OCPD Activation | Yes, clears faults by tripping the protective devices such as breakers and fuses. | No, does not clear faults but Dissipates fault current or surges to earth. |

| Path Type | Provides a low impedance fault current path. | Provides a connection to earth ground. |

| Continuity | Can be spliced with standard methods. | Must be continuous or use irreversible splices. |

| Connects To | Equipment enclosures, raceways, exposed metallic parts | Grounding electrodes (rods, water pipes, etc.) |

| Applicable Circuits | Branch circuits, feeders, and subpanels and all circuits for safety purposes. | Service equipment, transformers, separately derived systems, and grounding electrodes. |

Good to Know:

- As per National Electrical Code (NEC) sections 250.118(A) and 250.119(A) Both Equipment Grounding Conductor (EGC) and Grounding Electrode Conductor (GEC) can be bare, covered or insulated. Copper, aluminum or copper-clad aluminum in the form of solid or stranded form can be used for grounding conductors. In addition, GEC (grounding electrode conductor shall not be used a equipment grounding conductors per NEC 250.118(B).

- A grounding conductor is known a Ground Wire (G) in NEC and Protective Earth (PE) in IEC.

- The NEC neither requires nor prohibits the use of color green for the identification of grounding electrode conductors (GEC). NEC – 250.119(A), 250.62 and 250.64.

Resources:

- Difference Between AC Ground and DC Ground?

- Difference Between Grounding, Earthing and Bonding

- Difference Between Neutral, Ground and Earth?

- Can you Combine AC and DC Ground in a Solar Installation?

- Will I Get an Electric Shock If I Touch the Ground Wire?

- Why Doesn’t DC System Require a Grounding System Similar to AC System?

- Why is the Grounding Wire Bare and Not Insulated?

- Why is the Ground Wire Size Smaller than the Hot Wire?

- Why is the Ground Wire Always Positioned Above the Overhead Power Lines?

- Why Must Neutral and Ground Wires Be Bonded in the Main Panel?

- Why are Neutral and Ground Wires Separated in a Subpanel?

- Why are Salt and Charcoal Added in Earthing Pit for Grounding?

- Difference Between GND, 0VDC, Common and Virtual Ground

- Is It Possible to Get Electrocuted by an Electric Vehicle?

- How Does the Grounding System Work in Aircraft & Submarines?

Related Electrical Wiring Tutorials:

- How to Size Equipment Grounding Conductor (EGC)?

- How to Size Grounding Electrode Conductor (GEC)?

- How to Size the Earth Conductor, Earthing Lead & Earth Electrodes?

- How to Size Service-Entrance Conductors and Feeder Cables?

- How to Size Feeder Conductors with Overcurrent Protection

- How to Size a Branch Circuit Conductors with Protection?

- How to Find the Proper Size of Circuit Breaker?

- How to Size a Load Center, Panelboards and Distribution Board?

- How to Determine the Right Size Capacity of a Subpanel?

- How to Find the Right Wire Size for 100A Service 120V/240V Panel?

- What is the Correct Wire Size for 100A Breaker and Load?

- How to Determine the Number of Circuit Breakers in a Panel Board?

- Design of Grounding / Earthing System in a Substation Grid

- Grounding and Methods of Earthing in PV Solar System

- How to calculate the Cable size for LT & HT Motors?

- What is the Right Wire Size for 15A Breaker and Outlet?

- What is the Suitable Wire Size for 20A Breaker and Outlet?

- How to Find the Proper Size of Wire & Cable in Metric & Imperial Systems

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

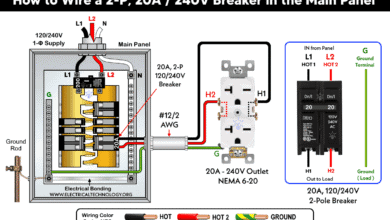

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

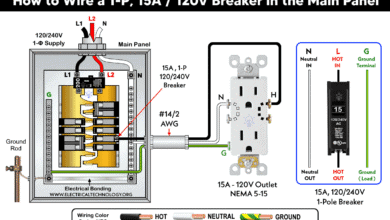

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel