Cable Size Calculation for LT & HT Motors

How to calculate the Cable size for LT & HT Motors?

Selecting the right cable size for the motor is an important parameter for the Industry whether it’s during Installation and Commissioning or during running condition. It is a very important aspect for Safety, Cost minimization and reduction of undesired losses. An undersized cable can burn during motor operation causing risk to human life, machine, infrastructure, loss of production and replacement cost.

Whereas an oversized conductor will incur unnecessary cost not only for the long run cables but also for cable termination materials used along with them i.e. lugs, glands, jointing kit (in case any fault occur in the future) and oversized cable tray. The cost of labor for laying of higher size cable will also be higher compared to respective lower size cable. Considering all these vital points it’s important to make an proper cable size calculation for our motor.

- Must Read: How to Calculate the Cable Size for Different Loads and Home Wiring (US & EU Solved Examples)

- Related Post: MV & HV Cable Termination to Equipment & Joints

Before we go in details, let’s clear the main difference between LT & HT Motors.

What is the difference between LT and HT Motors?

Well, as the word LT (Low Tension i.e. Low Voltage) and HT (High Tension i.e. High Voltage) or low torque and high torque respectively describe the whole story itself.

its also depends on the availability of supply voltage,i.e. in USA and EU,

LT Motors ranges = 230V – 415V

HT Motors ranges = 3.3 kV, 6.6kV – 11kV

while keep in mind that LT motors need more current than HT motors.

in other regions, they classified LT Motor under 1kV & HT Motor Over 1kV.

Now we have to discuss the main topic that’s how to calculate the cable size for motors?

Cable Size Calculation of 125 Kw LT Motor

Motor KW = 125

Pf = 0.8, Efficiency = 94%

System Voltage, V1 = 415

Cable length = 200 m

Load Current = P / (1.732 x V x Pf x Eff) —> (P = √3 x Vx I CosΦ = for three phase circuits)

= 125000 / (1.732 x 415 x 0.8 x 0.94)

~ 230 A

This is the full load current cable needs to cater in Ideal condition. But in practical situation, there are several derating factors which need to be considered.

The current rating given for the cables is defined for ambient temp of 40* C. If the ambient temp is greater than that, cable current carrying capacity derates.

Suppose our cable is in Air laid on cable tray,

- You may also read: What is Stepper Motor: Construction, Types and Modes of Operation

| Air Temperature in Deg. | 20° | 25° | 30° | 35° | 40° | 45° | 50° | 55° | |

| Normal PVC | 1.32 | 1.25 | 1.16 | 1.09 | 1.00 | 0.90 | 0.80 | 0.80 | |

| De-Rating factors | HR PVC | 1.22 | 1.17 | 1.12 | 1.06 | 1.00 | 0.94 | 0.87 | 0.80 |

| XLPE | 1.20 | 1.16 | 1.11 | 1.06 | 1.00 | 0.95 | 0.88 | 0.82 | |

Rating factors related to variation in ambient air temperature

Temperature Correction Factor, K1 when cable is in the Air = 0.88 (for 50* Amb temp & XLPE cable)

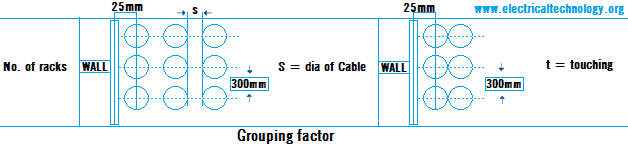

Grouping of cables also derates cable’s current carrying capacity. If many cables are grouped together, they will all heat up. The heat won’t be able to dissipate properly hence it will warm up the cable itself and those in its contact. This will raise the temperature further. Hence we have to derate the current carrying capacity of the cable according to the grouping factor.

Let’s go for worst case scenario, i.e. 3 trays parallel to each other having 9 cables each touching to each other.

| No. of Racks | No. of Cables per Rack | No. of Cables per Rack | ||||||||

| 1 | 2 | 3 | 6 | 9 | 1 | 2 | 3 | 6 | 9 | |

| 1 | 1.00 | 0.98 | 0.96 | 0.93 | 0.92 | 1.00 | 0.84 | 0.80 | 0.75 | 0.73 |

| 2 | 1.00 | 0.95 | 0.93 | 0.90 | 0.89 | 1.00 | 0.80 | 0.76 | 0.71 | 0.69 |

| 3 | 1.00 | 0.94 | 0.92 | 0.89 | 0.88 | 1.00 | 0.78 | 0.74 | 0.70 | 0.68 |

| 6 | 1.00 | 0.93 | 0.90 | 0.87 | 0.86 | 1.00 | 0.76 | 0.72 | 0.65 | 0.66 |

Table: Cable Grouping Factor (No of Tray Factor), K2 = 0.68 (for 3 trays having 9 cable each)

Total derating factor = K1 x K2

= 0.88×0.68 = 0.5984

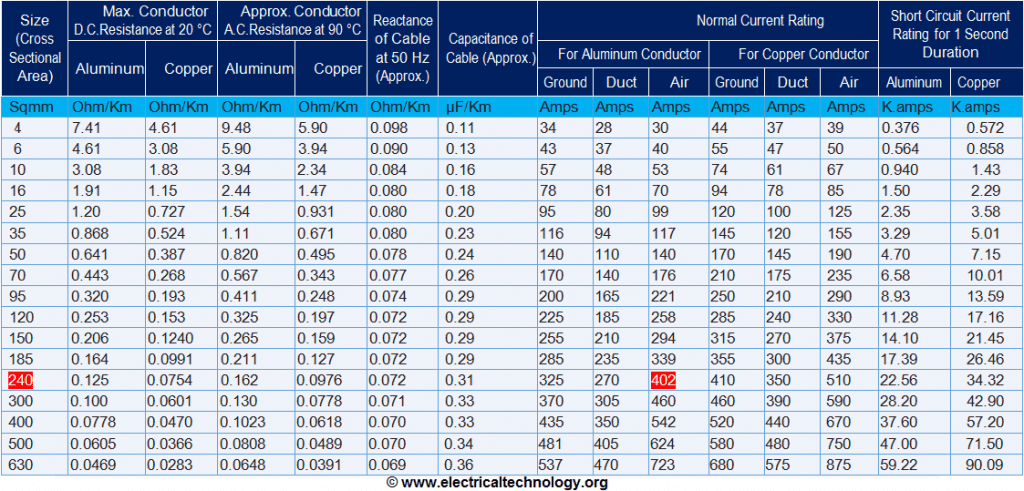

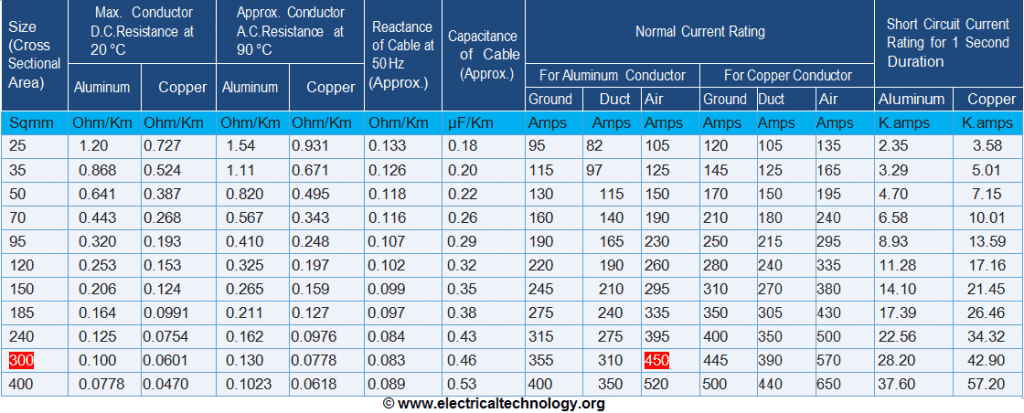

Let’s select 1.1 KV, 3 core, 240 Sq.mm, Aluminum, XLPE, Armored cable for single run

Click to enlarge the table

Technical Details For 1.1 KV, 3 Core, Aluminum/Copper Conductor, XLPE Insulated, Armored Cables

Current capacity of 240 Sq.mm XLPE Armored aluminum cable in Air is 402 Amp

Total derating current of 240 Sq.mm Cable = 402×0.5984 = 240.55 Amp

Resistance = 0.162 Ω / Km and

Reactance = 0.072 Ω / Km

- You may also read: Brushless DC Motor: Construction, Working Principle & Applications

| Estimated Voltage Drops in PVC/XLPE Aluminum Cables For A.C. System | ||||

| (Voltage drop – Volts/Km/Amps) | ||||

| Nominal Area of Conductor (Sq. mm) | P.V.C. Cable | XLPE Cable | ||

| Single Phase | Three Phase | Single Phase | Three System | |

| 1.5 | 43.44 | 37.62 | 46.34 | 40.13 |

| 2.5 | 29.04 | 25.15 | 30.98 | 26.83 |

| 4 | 17.78 | 15.40 | 18.98 | 16.44 |

| 6 | 11.06 | 9.58 | 11.80 | 10.22 |

| 10 | 7.40 | 6.41 | 7.88 | 6.82 |

| 16 | 4.58 | 3.97 | 4.90 | 4.24 |

| 25 | 2.89 | 2.50 | 3.08 | 2.67 |

| 35 | 2.10 | 1.80 | 2.23 | 1.94 |

| 50 | 1.55 | 1.30 | 1.65 | 1.44 |

| 70 | 1.10 | 0.94 | 1.15 | 1.00 |

| 95 | 0.79 | 0.68 | 0.83 | 0.70 |

| 120 | 0.63 | 0.55 | 0.66 | 0.56 |

| 150 | 0.52 | 0.46 | 0.55 | 0.48 |

| 185 | 0.42 | 0.37 | 0.44 | 0.40 |

| 240 | 0.34 | 0.30 | 0.35 | 0.30 |

| 300 | 0.28 | 0.26 | 0.30 | 0.26 |

| 400 | 0.24 | 0.22 | 0.24 | 0.22 |

| 500 | 0.23 | 0.20 | 0.23 | 0.20 |

| 630 | 0.20 | 0.18 | 0.21 | 0.18 |

| 800 | 0.19 | – | 0.20 | – |

| 1000 | 0.18 | – | 0.18 | – |

Voltage drop, V2 = 0.3 Volts/Km/Amp (as per Havell’s brochure)

= 0.3 x 230 x (200 / 1000)

= 13 V

Terminal voltage at Motor, V2 = 415 -13 = 402 V

% Drop = (V2 – V1) / (V1)

= (415 – 402) x 100 / (415)

= 3.13%

To decide 240 Sq.mm cable, cable selection condition should be checked

- Cable derating Amp (240.55 Amp)is higher than full load current of load (230 Amp) = OK

- Cable voltage Drop (3.13%)is less than defined voltage drop (10%) = OK

- Cable short circuit capacity (22.56 KA) is higher than system short circuit capacity at that point ( X KA) = OK

Related Post: Servo Motor – Types, Construction, Working, Controlling & Applications

240 Sq.mm cable satisfied all three condition, so it is advisable to use 3 Core 240 Sq.mm cable.

- You may also read: What is Motor Efficiency & How to improve it?

Cable Size Calculation for 350 KW HT Motor

In case of LV system cable can be selected on the basis of its current carrying capacity and voltage drop but in case of MV/HV system cable short circuit capacity is an important/deciding factor. So in case of HT motor, the cable short circuit capacity alone is enough to determine the cable size as rest two parameters will automatically follow.

Consider the below example:

Motor KW = 350

Pf = 0.8, Efficiency = 94%

System Voltage, V1 = 6.6 KV

Cable length = 200 m

Load Current = P / (1.732 x V x Pf x Eff)

= 350000 / (1.732 x 6600 x 0.8 x 0.94)

= 41 A

Suppose Short circuit level/Fault level for H.T. system, Ish (for duration t=1sec) = 26.2 KA

With Aluminum conductor, XLPE insulated cable =

= 278.72 Sq.mm

Hence nearest higher size 300 sq mm is required.

We can see from the below table also that the short circuit capacity of 300sqmm cable is 28 KA which is more than our fault level.

- You may also read: Star Delta 3-phase Motor Automatic starter with Timer

Click image to enlarge

(6.6KV UNEARTHED / 11KV EARTHED GRADE)

Technical Details For 6.6 KV, 3 Core, Aluminum/Copper Conductor, XLPE Insulated, Armored Cables

We can see that this will automatically satisfy other two conditions also.

Let’s select 6.6 KV, 3 core, 300 Sq.mm, Aluminum, XLPE, Armored cable for single run

Temperature Correction Factor, K1 when cable is in the Air = 0.88 (for 50* Amb temp & XLPE cable)

Cable Grouping Factor (No of Tray Factor), K2 = 0.68 (for 3 trays having 9 cable each)

Total derating factor = K1 x K2 = 0.88 x 0.68 = 0.5984

Current capacity of 300 Sq.mm XLPE Armored aluminum cable in Air is 450 Amp

Total derating current of 300 Sq.mm Cable = 450×0.5984 = 269.28 Amp

Resistance = 0.130 Ω / Km and

Reactance = 0.0999 Ω / Km

Voltage drop = 0.26 Volts / Km / Amp (as per Havell’s brochure)

= 0.26 x 200 x 41 / 1000

= 2.132 V

Terminal voltage at Motor, V2 = 6600 – 2.132 = 6597.868 V

% Drop = (V1 – V2) / (V1)

= (6600 – 6597.8) x 100 / (6600)

= 0.032%

To decide 300 Sq.mm cable, cable selection condition should be checked

- Cable derating Amp (269.28 Amp) is higher than full load current of load (41 Amp) = OK

- Cable voltage Drop (0.032%)is less than defined voltage drop (5%) = OK

- Cable short circuit capacity (28.20 KA) is higher than system short circuit capacity at that point (26.2 KA) = OK

300 Sq.mm cable satisfied all three condition, so it is advisable to use 3 Core 300 Sq.mm cable.

You may also read:

- Three Phase Motor Power & Control Wiring Diagrams

- Electrical Wire & Cable Size Calculator (Copper & Aluminum)

- How to Find the Size of Earth Conductor, Earthing Lead & Earth Electrodes?

Please give me the Chart for the cables and glands, lugs

Dear Sir!

Please explain help me,

For LT motor 125kw, Pf = 0.8, Efficiency = 94%, System Voltage, V1 = 415, Cable length = 200 m

1. Voltage drop, V2 = 0.3 Volts/Km/Amp (as per Havell’s brochure)

= 0.3x217x200/1000 = 13 V

I thinks this is wrong, because sysatem voltage is 415v not 217v, So: V2=0.3x415x200/1000 = 24.9v

Is that true Sir? please anser help me. Thanks

2. About Cable voltage Drop (3.13%) is less than defined voltage drop (10%) = OK

Could you help me understand about 10%?. The voltage drop 10% is your experienced or what’s standard?.

Thanks & have a nice day!

Dear sir,

There is some typing error, instead of 217, it should be the Calculated full load Current i.e. 230 Amp. thus 217 is not the voltage but it is current and Voltage V2 is voltage drop in Volts in one Km length with one Amp Load current.

Now, here cable length is 200 mtr., so it is divided by 1000 to convert the 200 mtr. in Km. & instead of 217 Amp it should be 230 Amp. Now multiply by the 0.3 i.e. Voltage drop in one km with one amp load current. Thus, actual Voltage drop in Volts would be

V2 = 0.3*230*200/1000 = 13.8 Volts

We have changed the values. Thanks for correction.

Dear Sir,

Please specified how will select the size any type of cable like control cable and power cable as well as core.

please provide me calculation.

Here is the step by step tutorial: How to select proper cable for installation ?

Dear Sir,

Please specified how will select the size any type of cable like control cable and power cable as well as core.

please provide me calculatio

You may find it here with examples

For underground cable CU cable, for 350KW, 6.6 KV. What will be calculation? Please help. I need actually 1500KW, 6.6KV undergroung cable 200m calculation?

For Current rating calculation , you consider line to line voltage ie 415 Volts , but for Voltage drop calculation you consider 230 Volts ie Line to neutral voltage. Is it TRUE ??

someone should help this question please.

A 30m long twin PVC installed cable carrying current from a switch board in domestic installation to a 4kw electric heater

1. Determine the minimum size of cable with the reference to IEER

2. Calculate the size of cable for the lightening 120m distance long is to be lighted by 40w lamp.