How to Find the Correct Wire Size for a 35A Breaker and Outlet Based on NEC?

Selecting the correct wire size for a 35A breaker and load circuit is crucial for both the safety of the appliance and the operator. The wire size must also comply with the National Electrical Code (NEC) NFPA – 70, IEC, IEEE, or other local codes to pass inspections.

A 35-amp breaker is available in standard sizes but is not as common as 15, 20, 30, and 40-amp breakers. They are used for high-power devices such as A/C condensers. For example, to avoid the unwanted tripping of a 30-amp breaker used with a 3,000W, 120V water heater element, you may upgrade to a 35-amp breaker to resolve the issue if it is related to ampacity or wire size.

A #8 AWG (copper or aluminum) wire is generally suitable for a 35-amp circuit. Understanding the factors involved in wire size selection and the specific applications of a 35A breaker and load circuit will ensure safe and effective electrical installations.

Suitable Wire Size for a 35A Breaker and Circuit

When installing a 35-amp breaker and load circuit, selecting the correct wire size is essential to ensure safety, efficiency, and compliance with NEC standards.

The NEC specifies that the minimum wire size for a 35-amp breaker is #8 AWG (American Wire Gauge), either copper or aluminum.

Based on NEC Table 310.16, the ampacity of #8 AWG wire is as follows:

#8 AWG Copper

- 40 amps at 60°C (140°F)

- 50 amps at 75°C (167°F)

- 55 amps at 90°C (194°F)

#8 AWG Aluminum

- 35 amps at 60°C (140°F)

- 40 amps at 75°C (167°F)

- 45 amps at 90°C (194°F)

Copper conductors are preferred for most residential and commercial applications due to their lower resistance and better conductivity compared to aluminum. Therefore, the correct wire size for 35-amp circuit is #8 AWG.

Good to know:

- For a 35A circuit breaker, the correct wire size is #8 AWG for both copper and aluminum.

- Use 10-2 with ground for 120V, 35-amp breaker, and load circuits.

- Use 10-3 with ground for 240V, 35-amp breaker, and load circuits.

- Longer runs (when the distance is more than 50 ft (15.25 meters) require an upgrade and larger wire gauge size to compensate for voltage drop.

-

According to the NEC – 310-16, add 20% of additional ampacity for every 100 feet (30.50 meters) of distance (for example between main panel and subpanel) to counter the voltage drop.

Selecting the Right Wire Size for a 35A Breaker

Selecting the correct wire size involves considering several factors, including the conductor material (copper or aluminum), circuit length, ambient temperature, and installation environment (e.g., in conduit or free air). The following example illustrates this:

Example:

Suppose you have a 1-pole or 2-pole 35A breaker installed in the main panel, and you need to wire it with a maximum of 35A load circuit. Follow these steps to find the correct wire size for a 35A breaker and load point, considering both continuous and non-continuous load circuits according to NEC guidelines.

Continuous Load Circuit

The NEC’s 125% rule states that the maximum overcurrent protection device (MOCP) should handle 125% of the continuous load. As a safety factor, no more than 80% of the continuous load should be connected to the Overcurrent Protection Device (OCPD).

35A × 80% = 28A

Based on this calculation, no more than 28A of continuous load should be connected to a 35A breaker.

When the minimum circuit ampacity (MCA) i.e. load circuit’s amperes are 28A, to determine the correct breaker size for this circuit:

28A × 125% = 35A

According to NEC Table 310.16, the #8 AWG wire size can carry 40A at 60°C (140°F) and 50A at 75°C (167°F).

Non-continuous Load Circuit

For non-continuous loads (e.g., general lighting circuits), the conductor size should be no less than 100% of the load. The same applies to overcurrent protection devices (OCPDs).

A 35A breaker can handle a maximum of 35A non-continuous load circuits, such as outlets and lighting points, while considering ambient temperature rating (Refer to 110.14(C) and 310.15(B)(2)).

How Many Amps Can a 35A Breaker Handle Safely?

A 35-amp breaker is designed to safely handle a maximum of 35 amps of current. The NEC specifies that breakers should not be loaded to more than 80% of their rated capacity for continuous loads (defined as a load lasting three hours or more). Therefore, a 35A breaker should be used for a maximum of 28A continuous load circuits.

35A × 80% = 28A

For short, non-continuous loads, the breaker can handle up to 35 amps safely.

- Use a 35A breaker for a 28A continuous load circuit.

- Use a 35A breaker for a 35A non-continuous load circuit.

These ratings comply with NEC Sections 210.19(A), 215.2, and 230.42(A) for continuous and non-continuous loads, and 110.14(C) for ambient temperature.

The above calculations are based on NEC Table 310.16 and 240.4(A) through (G), illustrating that the 8 AWG copper wire size can carry 40A at 60°C (140°F) and 50A at 75°C (167°F) which is the suitable size to use with a 35-Amp breaker.

How Many Watts Can a 35A Breaker and Outlet Hold?

The power capacity of a 35-amp breaker can be calculated using the formula:

120V Circuit

In a standard 120V circuit, the max power a 35A breaker can hold:

35 A × 120 V = 4,200 W

Applying the safety factor:

35 A × 80% = 28 A

Based on this calculation, you may put 3,360 watts of load on a 35A breaker.

28A × 120V = 3,360 watts

It means, you may use 35A breaker with a 120V, 3kW water heater element.

240V Circuit

A 2-P, 35A breaker in 240V circuit can hold the maximum power:

35 A × 240 V = 8,400 W

Applying the safety factor:

35 A × 80% = 28 A

No more than 6,720 watts of load should be connected to a 35A breaker and outlet:

28A × 240V = 6,720 watts

For example, you may use a 35A breaker with a 240V, 6kW water heater element.

These calculations assume that the breaker is not operating at 100% of its capacity simultaneously for continuous load circuits. For continuous loads, the safe wattage is 80% of these values:

- 120V Circuit (Continuous Load): 3,360 W

- 240V Circuit (Continuous Load): 6,720 W

How Many Outlets Can be Installed on a 35A Breaker?

35A breaker are used as dedicated circuit for high wattage load circuits. It is not against the code and not recommended to use multiple general-purpose outlets such types of circuits. Mathematically, a 35-Amp circuit breaker can support 18 outlets.

The NEC recommends that a circuit should not be loaded to more than 80% of its capacity to allow for safety margins. For a 35A breaker, the maximum continuous load should be:

35A × 0.8 = 28A

If each outlet is assumed to draw 1.5A, you can estimate the number of outlets by dividing the maximum continuous load by the per-outlet load:

28 A ÷ 1.5 A ≈ 18 outlets

This is a rough estimate and assumes that the outlets will not be heavily loaded. If heavier appliances are expected, fewer outlets should be used.

A 35A circuit might be used to supply a single appliance. For example, large air conditioner, or several outlets in a workshop for heavy-duty tools and machines.

Refer to NEC Table 210.21(B)(3) for receptacle ratings for various circuit sizes.

Suitable Types of Cables for a 35-Amp Breaker and Outlet

- THHN/THWN: These are common types of wire used in conduit for general-purpose indoor applications. They have a thermoplastic insulation that can handle high temperatures.

- NM-B (Non-Metallic Sheathed Cable): Suitable for indoor residential wiring where the cable is protected from physical damage.

- UF-B (Underground Feeder Cable): Suitable for direct burial outdoors or for applications where the cable will be exposed to moisture or other harsh conditions.

Applications of a 35-Amp Breaker and Outlet

A 35-amp breaker and corresponding outlets are typically used in scenarios where moderate to high power demands are required. Here are some common applications:

- Electric Vehicle (EV) Charging: EV chargers often require circuits with ratings between 20A and 50A. A 35A breaker could be used for a mid-range Level 2 EV charger.

- Air Conditioning Units: Central air conditioning systems or large window units that require a dedicated circuit could use a 35A breaker.

- Water Heaters: Certain residential water heaters, especially tankless models, may require a 35A circuit depending on their power ratings.

- Electric Cooktops: Some electric cooktops or stoves that draw more current than standard appliances might be suitable for a 35A breaker.

- Workshop Tools: Larger power tools, such as table saws, air compressors, or welders, in a workshop might need a 35A breaker if they have higher power requirements.

- Dedicated Circuits: Applications using a 35A breaker typically require dedicated circuits to avoid overloading and ensure safe operation.

- Breaker Compatibility: Ensure that the breaker type (standard, GFCI, AFCI) matches the application and complies with the NEC and local codes.

Good to Know:

- The ampere rating of a single receptacle installed on an individual branch circuit should not exceed that of the branch circuit.

- The above calculations for breaker and wire sizes apply only to purely resistive load circuits, such as lighting.

- For inductive loads (motors and HVAC), refer to NEC Article 440, particularly sections 440.22 and 440.32. If not sure, consult an HVACR contractor, instructor, and electrician.

- A 35A branch circuit needs #8 AWG wire size for copper – NEC Table 210.24.(1).

- A 35A outlet can be used for a 28A continuous load and a maximum 35A non-continuous load (210.19(A)).

- It is against code to use a 40A outlet to draw 40A on a 35A breaker.

- It is against code to use smaller gauge wire sizes (e.g., using 10, 12 AWG) instead of 8 AWG wire with a 35A breaker.

- According to NEC 210.21(B)(3), it is permissible to use a 30A outlet on a 35A circuit if there are multiple receptacles on the circuit.

- Important Note: If you install a 30A outlet on a 35A circuit, it should only be used for a maximum of a 28A load. Drawing more than 28A simultaneously from a 35A breaker will overheat the circuit, potentially causing serious injury and fire hazards.

Resources:

Wire Sizes for Standard Breakers, Outlet and Branch Circuits

- Wire Size for 15A Breaker and Outlet

- Wire Size for 20A Breaker and Outlet

- Wire Size for 25A Breaker and Load

- Wire Size for a 30A Breaker and Outlet

- Wire Size for a 35A Breaker and Load … (You are Here)

- Wire Size for a 40A Breaker and Load

- Wire Size for 45A Breaker and Load

- Wire Size for 50A Breaker and Outlet

- Wire Size for 55A Breaker and Load

- Wire Size for 60A Breaker and Outlet

- Wire Size for 70A Breaker and Load

- Wire Size for 80A Breaker and Load

- Wire Size for 90A Breaker and Load

- Wire Size for 100A Breaker and Load

Sizing Wires for for General Wiring Installations

- Right Wire Size for100A Service Entrance and Load in AWG for 120V/240V Panel

- What is the Right Wire Size for a 4.8kW, 240V Range: #10 or #12?

- How to Find the Proper Size of Circuit Breaker?

- How to Find the Proper Size of Wire & Cable In Metric & Imperial Systems

- How to Size a Breaker and Wires in AWG with EGC for Load?

- How to Size a Load Center, Panelboards and Distribution Board?

- How to Size a Branch Circuit Conductors with Protection?

- How to Size Feeder Conductors with Overcurrent Protection

- How to Size Service-Entrance Conductors and Feeder Cables?

- How to Size Equipment Grounding Conductor (EGC)?

- How to Size Grounding Electrode Conductor (GEC)?

- How to Size Motor Starter & Contactor – NEMA & NEC

- How to Size Motor Branch Circuit Conductors and Cables

- How to Determine the Number of Circuit Breakers in a Panelboard?

- How to Find Voltage & Ampere Rating of Switch, Plug, Outlet & Receptacle

- American Wire Gauge “AWG” Chart – Wire Size & Ampacity Table

- American Wire Gauge “AWG” Calculator – AWG Size Chart & Table

- Standard Wire Gauge “SWG” Calculator – SWG Size Chart & Table

- AWG/SWG to mm/mm2, inch/inch2 & kcmil Calculator & Conversion

- How to Wire 120V & 240V Main Panel? Breaker Box Installation

- How to Wire a Subpanel? Main Lug Installation for 120V/240V

- How to Wire an Outlet Receptacle? Socket Outlet Wiring Diagrams

- Wire and Cable Size Calculator in AWG

- Electrical Wire and Cable Size Calculator (Copper & Aluminum)

Wiring 30A Outlets with 30A Breakers

- How to Wire a 30A – 120V Outlet – NEMA 5-30 Receptacle

- How to Wire a 30A – 240V Outlet – NEMA 6-30 Receptacle

- How to Replace a 30A – 120/240V Outlet – NEMA 10-30R?

- How to Wire a 30A – 125/250V Outlet – NEMA 14-30 Receptacle

- How to Wire a 30A – 125V Outlet – NEMA TT-30 Receptacle

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

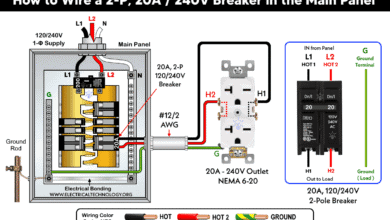

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

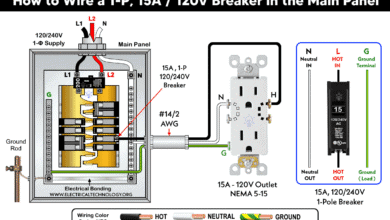

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel