Earth – Ground Resistance Tester – Construction, Working and Applications

Earth or ground resistance testers play a vital role in assessing the effectiveness of grounding and earthing systems by measuring ground resistance and soil resistivity. It is essential to measure and maintain the appropriate ground resistance and earth resistivity for a proper earthing and grounding system.

In power systems and electrical installations, all machines and external metallic bodies are connected to an effective ground rod/earth electrode. In case of a fault, the leakage current will easily pass to the ground source, hence protecting the person working on machines and equipment.

Earth / Ground Resistance

Earth resistance refers to the resistance between the earth electrodes and the earth. Earth has zero resistance due to its large cross-section (i.e., Earth’s resistance is assumed to be zero for reference). Since the earth resistance is zero, the potential of the earth is also assumed to be zero.

The resistance between earth and ground rod / earth electrode depends on the following.

- (i) Internal resistance of earth electrodes / ground rods (almost negligible).

- (ii) Contact resistances between electrode and earth.

- (iii) The resistance of the soil between the two electrodes at which the measurement is made.

However, the electrodes themselves have very low (or negligible) resistance. Similarly, the soil resistance between the electrodes is almost negligible. In reality, earth resistors consist of the contact resistances between the electrodes and the earth.

Good to Know:

- According to NEC 250.56, the maximum grounding resistance is 25 ohms, and 50 ohms for sensitive applications. An additional ground rod needs to be installed if the ground resistance exceeds 50 ohms.

- According to IEC/BS EN 62561-2:2012, good earth resistance is 5 – 10 ohms.

- Recommended grounding resistance per IEEE and NFPA standards is typically < 5 ohms, also applicable to telecommunications.

Related Post: How to Test the Earth Fault Loop Impedance – Various Methods

What is a Ground / Earth Tester?

The Earth tester, also known as a ground resistance tester or earth resistance meter, is an essential instrument used to determine the ground resistance and earth resistivity for grounding and earthing systems.

It is a modified version of the Megger (also known as an earth megger), which is used to measure and calculate the ground resistance between the ground, ground rod/earth electrode, and wiring installations.

Earth testers range from zero to 50 ohms, zero to 500 ohms, zero to 1500 ohms and zero to 3000 ohms. They are available in digital and analog formats, while the old-school ones are manually operated by hand.

Construction of Ground Resistance Testers:

Modern digital ground resistance testers, such as those manufactured by Megger or Fluke, are typically handheld devices with robust construction designed to withstand field conditions and incorporate various built-in features.

The construction of an earth tester is similar to a megger, except that a megger has two terminals, while an earth/ground resistor may have three or four terminals.

Old-school manual earth testers consist of a hand-driven DC generator, a current coil, a potential coil, a fixed resistor, a current-limiting resistor, a constant magnet, and a scale with a pointer.

The potential and current coils are fixed on a common axis, making a 90° angle and moving freely inside the magnetic field produced by the magnets. The deflection (pointer) of the earth tester is always on zero.

The key components include:

- Current Source: Generates a controlled current to be injected into the ground.

- Voltage Measurement Circuit: Measures the potential difference between the ground electrodes.

- Display Unit: Shows the ground resistance value in ohms or other relevant units.

- Controls and Settings: Allow users to configure test parameters and select measurement modes.

Related Post: How to Measure Ground Resistance? – Testing Earth Resistance

Working Principles of Earth Resistance Tester

Earth testers operate based on Ohm’s Law, where the measured ground resistance (R) is determined by dividing the potential difference (V) by the injected current (I). The formula is expressed as R = V/I. The tester automatically calculates the ground resistance based on these principles.

A specific current is injected into the “CE” spike and the earth electrode/ground rod “E/G,” both positioned at a specific and equal distance inside the earth. The potential spike “PE” is positioned between the current spike ‘CE’ and the ground rod or earth electrode “GE.” Now, it measures the potential difference between the potential spike “PE” and the ground/earth electrode “GE.” Using Ohm’s law, the ground resistance can be calculated as follows.

RE = V ÷ I

Where

- RE = Ground / Earth Resistance

- V = Potential Difference

- I = Current

When the ‘Test/Measure’ button is pressed (or in manual testers, when the handle attached to the generator is rotated at a uniform speed, i.e., 160 revolutions per minute), current is injected and flows in the electrode CE (via C1 and C2) and the earth electrode “G/E.” Pressure Coils P1-P2 are installed between Spike P and Earth. As there is no voltage drop in the spike CE, the contact resistance drop affects the pressure coil, which moves the pointer and shows the readings. These values are not affected by the earth resistance.

Note that earth resistance decreases rapidly with temperature and ground salt concentration; that’s why a mixture of salt and charcoal is added to the earth pit to decrease the value of earth-ground resistance.

- Related Post: How to Measure Resistivity of Earth Using Wenner Method?

Positioning of Electrodes:

Proper electrode positioning is crucial for accurate earth resistance measurements. The Wenner 4-Point Method is commonly used, involving the arrangement of four equally spaced electrodes. The spacing and depth of the electrodes play a significant role in obtaining reliable results.

Generally, the distance between spikes and the electrode is three times greater than the length of the ground rod or earth electrode. Alternatively, the length of the spike should be 1/3 of the distance between spikes.

Example:

If the distance between the spikes is “a,” the length of the rod or electrode should be 1/3 of “a.”

e.g.

Length of Ground Rod = 2.5 m (8.2 ft.)

Distance between the spikes and rods = 7.5 m (24.6 ft.).

Always refer to the user manual for the desired model or consult a licensed electrician to ensure compliance with proper codes and guidelines.

Related Posts:

- How to Test Grounding / Earthing System using a Multimeter?

- How to Test Earthing – Grounding System using a Light Bulb?

How to Measure Ground Resistance?

We have published a detailed post on measuring and calculating ground or earth resistance using various methods, such as 2-point, 3-point, 4-point (Wenner method), fall of potential, clamp-on test method, etc. Additionally, premium resources related to grounding and earthing systems are linked in this post, as well as in the bottom section.

Difference Between Earth Testers and Meggers:

While both earth testers and meggers (megohmmeters) are used in electrical testing, they serve different purposes.

Earth testers (with three or four terminals) focus on measuring ground resistance and soil resistivity, ensuring the integrity of grounding systems.

Meggers (with two terminals), on the other hand, primarily assess insulation resistance in electrical circuits. Earth testers are specifically designed for grounding applications, providing accurate and reliable measurements in this context.

What Does an Earth Resistance Tester Do?

An earth resistance tester evaluates the resistance offered by the ground to the flow of electric current. Its primary functions include:

- Injecting Current: The tester sends a known current into the ground through the grounding system.

- Voltage Measurement: It measures the potential difference between various ground electrodes.

- Calculating Resistance: The tester applies Ohm’s Law to determine the ground resistance.

Related Posts:

- Electrical Earthing and Grounding – Methods, Types and Installation

- Protective Multiple Earthing (PME) – TN-C-S – (MEN) and PNB

- How to Measure Earth Loop Resistance Using Ammeter and Voltmeter?

- Design of Grounding / Earthing System in a Substation Grid

- Why are Salt and Charcoal Added in Earthing Pit for Grounding?

- What is the Purpose of Ground Wire in Overhead Transmission Lines?

- Difference Between Grounding, Earthing and Bonding

- What is the Difference Between Neutral, Ground and Earth?

- Difference Between Real Ground and Virtual Ground

- Why is the Grounding Wire Bare and Not Insulated?

- Why is Copper Rod Used as Ground Rod in Grounding / Earthing System?

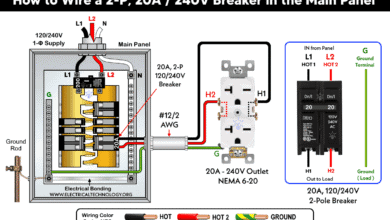

How to Wire a Tandem Breaker for 120V and 240V Circuits

How to Wire a Tandem Breaker for 120V and 240V Circuits How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel