Is there a Legitimate Difference Between a NEMA 14-50 Standard Receptacle and a NEMA 14-50 EV-Grade Heavy Duty Receptacle?

$10-15 standard outlets and $40-80 heavy-duty outlets/receptacles are both NEMA 14-50Rs. Both types are 3-pole, 4-wire, and rated for 50-amp at 125/250V, single-phase AC supply. While they may appear almost identical, they are not built the same. The EV-rated version is generally constructed with higher quality and durability compared to the standard version.

Both NEMA 14-50 receptacles (standard vs EVs) have the following four terminals:

- G (green screw): Ground

- X (brass screw): Indicates HOT 1

- Y (brass screw): Indicates HOT 2

- W or N (silver screw): Neutral

The EV-branded NEMA 14-50R is built tougher with high-impact nylon housings, pressure-wire terminals, and heavier-duty contacts. It’s specifically designed to withstand continuous charging for hours and endure hundreds of plug-in/plug-out cycles.

By contrast, the cheaper standard outlet can work, but it’s intended more for kitchen ranges, RVs, or occasional heavy loads, and not as a daily-driver EV charging outlet.

Good to Know:

4 Nos of wires (two hots, 1 neutral and 1 ground) are required to wire a NEMA 14-50 outlet. Based on NEC Table 310.16, the suitable wire size for a 50A circuit (breaker and outlet) is #6 AWG copper wire (recommended) and #4 AWG Aluminum or copper-clade aluminum. Similarly, minimum #10 AWG can be used as equipment ground conductor (EGC) as per NEC Table 250.122.

Let’s have a recap what are they and how they are made to handle the continuous and non-continuous load in residential and commercial applications.

Standard NEMA 14-50R

A NEMA 14-50R receptacle is a 3-pole, 4-wire, 50-amp, 125/250 V outlet. The standard (or “ordinary”) version is widely used with NEMA 14-50P plugs for ranges, RVs, welders, and more recently, EV charging.

If it’s UL-listed and properly manufactured, it should safely handle 50-amp non-continuous, or 40-amp continuous load per the NEC 80% rule. This is sufficient for most EV charging stations and vehicles.

EV-Grade NEMA 14-50R

Manufacturers such as Hubbell, Bryant, Leviton, Eaton, and others market upgraded “EV” or “Plus” versions of NEMA 14-50R and 6-50R outlets. While these are not a different NEMA configuration (they remain standard NEMA 14-50Rs), they are industrial-grade receptacles with critical enhancements:

- Heavier contacts made of thicker brass/copper for better grip and lower resistance.

- Improved heat dissipation, reducing the risk of overheating, failure, or fire under continuous high loads.

- Stronger terminal lugs that support larger gauge copper wires (#4, #6, or #8 AWG) with more secure torque.

- Durability for industrial/commercial use, designed for longer lifespans and frequent plug/unplug cycles.

- Some models carry “Extra Heavy-Duty” or “EV Ready” ratings, confirming suitability for continuous 40 A EV charging.

- UL-listed EV-grade versions are certified to handle 50-amp continuous loads for extended periods.

Good to Know: Many EV-grade NEMA 14-50 receptacles feature a green vehicle symbol. The vehicle sign indicates that the outlet is specifically designed for heavy-duty EV charging and other demanding applications.

Difference Between Standard vs EV Grade

The key difference between an ordinary and an EV-rated (heavy-duty) NEMA 14-50R receptacle is in their design and durability.

- An ordinary 14-50R is a standard residential-grade outlet, intended for intermittent use with appliances like ranges, ovens, and RVs.

- An EV-grade 14-50R is an industrial-grade outlet, built with heavier internal components, designed to safely handle the continuous high-current draw of electric vehicle charging.

For example, let’s examine how they handle continuous and non-continuous loads over long durations.

Standard 50-Amp Receptacle

According to NEC 210.19(A), only 80% of the rated current should be used for continuous loads (defined as loads lasting more than 3 hours). In other words, the outlet should be sized at 125% of the simultaneous load current. In practice, this means:

According to NEC 210.19(A), only 80% of the continuous load (which lasts more than 3 hours) should be connected the outlet and receptacle. In other words, the outlet should be sized at 125% of the simultaneous load current.

50A × 80% = 40 Amp

Therefore, an ordinary 50-amp receptacle can safely support 40-amp continuous load, which is fine for most appliances.

Heavy-Duty 50-Amp Receptacle for EVs

EVs are considered continuous loads since they can operate for 6 – 12 hours. For this reason, a heavy-duty 50-amp receptacle is recommended, as it can safely withstand and handle 50-amps of continuous load for extended periods.

50-amp EVs receptacles can be continuously used for Hours

The following images show the differences in lugs, contacts, and materials used between a standard 14-50 outlet and an EV-grade 14-50 outlet.

If Both Receptacles Are Rated for 50-Amps, Why Shouldn’t I Use a Standard One for EV Charging?

It is good to know that the standard 50-amp receptacle can also be used for 50-amp non-continuous load circuits such as ranges, stoves, ovens, and burners. However, these types of loads are not operated for long durations, even during Christmas and Thanksgiving. It’s rare to have everything running on high for four hours straight. Even if oven is heated up and then goes on and off so the load is not a continuous load.

“Normal receptacles” may meet the specifications of 50-amps, but they’re not designed to handle continuous 40A loads for hours at a time on a daily basis.

If you look inside the slots of a standard receptacle, you’ll often notice that the contacts only cover about half of the slot area. Less contact area means higher resistance, which generates more heat. As the heat builds up, the contacts begin to flex, reducing the contact area even further. This creates a destructive cycle until the connection eventually shifts enough to lose proper contact and open the circuit.

By that stage, the receptacle is often visibly melted and deformed, with scorch marks extending up the wall, and the plug itself usually damaged beyond repair.

This is why ordinary 50-amp receptacles are not a suitable option for EVs and other high-power appliances. Instead, heavy-duty industrial-grade receptacles and outlets should be used for electric vehicle charging in both plug-in and hardwired installations.

The following images show melted 50-amp standard 14-50 receptacles that were used for EV charging.

Click image or open in a new tab to enlarge

Comparison Between 50-Amp Standard vs Heavy Duty Industrial Grade Receptacles

Below is the comparison table showing the differences between standard and EV-grade 50-amp 14-50 receptacles.

| Feature | Standard NEMA 14-50R “50-Amp” | Heavy Duty NEMA 14-50R “50-Amp” |

| Rating | 50-amp max at 125/250V – 1-Phase | 50-amp continuous at 125/250V – 1-Phase |

| Grade | Domestic and Residential grade for up to 50-Amp | Industrial Commercial grade receptacle for 50-Amp |

| Construction | Designed for residential or light-commercial use with cheaper, lighter-duty materials. | Engineered with heavy-duty, industrial-grade materials to handle greater heat and stress. |

| Charging load | Built for intermittent, not continuous, high-amp use. The cycling of a stove or dryer is less demanding than the constant pull of an EV. | Specifically designed to sustain the continuous, high-current electrical load that EV charging requires for extended periods. |

| Operating Temp. | -40°C to 60°C | -40°C to Max. continuous 75°C |

| Safety and durability | Repeatedly plugging and unplugging a charger, combined with the strain of continuous high power, can cause contacts to loosen, leading to increased resistance, heat, and potential fire risk. | Upgraded components, such as a stronger clamping mechanism and heavier internal contacts, create a more secure connection that prevents overheating and lasts longer. |

| Contact force | Uses standard contact mechanisms for plug blades. | Features increased contact force on the plug blades, which ensures a more secure and reliable connection and minimizes the risk of power interruptions or fluctuations. |

| Weight | heavy | 2-3 times heavier |

| Cost | Typically much cheaper and available at any home improvement store. | More expensive due to higher-quality materials and construction. |

| Manufacturer marking | Has the standard 14-50R markings. | Often features additional branding, such as a “Heavy Duty,” “Industrial Grade,” or “EV Charging” designation, and may have a green icon of an electric car. |

FAQs

What is the newer version of the 50-Amp (NEMA 14-50) outlet for?

There isn’t a “new” version of the NEMA 14-50. The difference is that standard outlets have been prone to melting under long-duration EV charging, since they weren’t designed for hours of continuous high current.

EV-rated versions are built with:

- High-impact, heat-resistant nylon housings

- Stronger screws and terminal lugs

- Heavier metallic contacts and copper blades

These improvements prevent overheating and wear during frequent plug/unplug cycles. This wasn’t a concern 15 years ago, but with the rise of EVs, industry had to address these weaknesses.

Which one should I use: Standard or Heavy-Duty outlet for EVs?

Always use the heavy-duty (EV-rated) receptacle, often marked with a green vehicle symbol.

- Standard outlets are fine for ovens and ranges that don’t pull that much amperage but not for hours-long continuous EV charging.

- EV-rated outlets have larger, stronger contacts and are designed to handle 40-50 amps continuously without overheating.

They may cost more, but the added safety and durability are worth the peace of mind. So you can sleep like a baby.

What happens if I use a Standard 50-Amp Receptacle for EV charging?

- If your EV draws only 28–32 amps continuously and you rarely unplug the cord, you may not face issues immediately.

- But at 40 amps or higher, a standard receptacle will eventually overheat, melt, or fail.

Some EVSE (chargers) have built-in temperature sensors that reduce charging speed or shut down to prevent damage. That means slower charging or interruptions, but this is still safer than risking an electrical fire.

If I can use a 50-amp outlet for ovens, why not for EVs?

Because ovens and stoves are not continuous-duty appliances (3+ hours of operation). EV charging is a continuous load that often lasts 6–12 hours.

- Standard outlets are made for appliances that stay plugged in but don’t pull max current for long durations. If used for EV charging, the heat generated from continuous operation can cause serious issues, such as melting, failure, or even not tripping the overload breaker.

- EV outlets are made with bigger, stronger contacts and better blade capture to handle repeated use and continuous current. They are designed to safely handle the 30-40 amp current for 6-10 hours without heating up.

That’s why you 100% need an EV-rated or industrial-grade receptacle for safe EV charging. This is because regular receptacles are not designed for constant, long-term use. If used in this way, they may overheat and melt, as they are intended only for intermittent usage.

Will an EV-rated 50-Amp outlet charge my car faster?

Not directly. The charging speed depends on the charger and the vehicle’s onboard system, not the outlet itself.

However, new chargers are designed to deliver power more quickly, and modern batteries are built to accept higher charging rates. As a result, older outlets may not perform well over the long term.

For example, five years ago, a standard outlet might initially draw 40 amps, but within an hour the charger and battery sensors (when detect a rise in temperature) would reduce the draw to 20 amps to prevent overheating.

This means you could experience slower charging when using an ordinary outlet with newer chargers. Over the past few years, significant improvements have been made, and the demand on outlets has increased accordingly.

If both look similar, why does an EV-rated outlet cost more?

While both standard and EV-rated NEMA 14-50R receptacles are rated for 50 amps, they are not built the same way. EV-rated receptacles cost more than standard 14-50R outlets because they are specifically designed for continuous high-current EV charging and must comply with stricter UL and NEC requirements compared to generic range or RV outlets.

Despite the higher price, the EV-rated receptacle is heavy-duty, whereas a standard one may overheat or even fail within a few months. Since EVs typically charge for 6 or more hours at nearly a full 50-amp draw, the EV-rated plug is engineered to handle this high amperage safely over extended periods.

One last time – Is there legit difference or just marketing? (I’m Not an Electrician)

Yes. The differences are legitimate, not just marketing.

- Standard 14-50Rs (low cost residential-grade) are designed for interval use and can overheat, loosen, or fail with daily EV charging.

- EV-rated (or “Plus”) 14-50Rs are industrial-grade with heavier brass/copper contacts, improved blade retention, and better heat dissipation. It can safely handle the continuous high-current draw of an Electric Vehicle (EV) charger and sustained load at extended time of periods.

The EV-rated version is a safer, more reliable choice for EV charging because it meets stricter safety standards and is engineered for the specific, continuous demands of charging electric vehicles, which standard receptacles are not. This makes them much safer for continuous EV loads.

Good to Know:

- NEC 2023 (Article 625.54) requires GFCI protection for NEMA 14-50 receptacles used for EV charging.

- In the case of double GFCI protection (since most newer chargers already have built-in GFCI protection), it can result in nuisance tripping. For instance, if the 50-amp outlet is cord-and-plug for EVs, and not hard-wired.

- Hardwiring an EVSE (instead of plug-in) is generally more reliable.

- The standard 14-50 outlet is even rated for 50-amp, but definitely not for hours and hours continuously.

- Based on NEC Table – 310.16, the recommended wire size for a 50-amp outlet is #6/2 NM-B (for indoor use) or THHN/THWN conductors in conduit, or UF cable for outdoor installations. Instead of #6 AWG copper, you may use #4 AWG Aluminum. Avoid using Romex beyond this application, as it is limited to a maximum of 50-amps.

- Use #6/3 cable if the charger requires a neutral.

- The suitable breaker size is 50-amp for 14-50R outlet.

- A 50-amp, 240V outlet must be on a dedicated circuit especially when used for for EV charging i.e. it cannot share with other loads for EV charging – NEC – 625.41.

Resources:

Related Posts:

- Difference Between Socket, Outlet and Receptacle

- Difference Between 15-Amp and 20-Amp Outlet?

- Difference Between 1-Pole and 2-Pole Breakers – NEC & IEC

- Should GFCI Protection Be in the Main Panel or Receptacle?

- What is the Right Wire Size for 15A Breaker and Outlet?

- How to Find the Number of Outlets on a Single Circuit Breaker?

- How to Find Voltage & Ampere Rating of Switch, Plug, Outlet & Receptacle

- Can you use 15A Breaker on 20A Circuit and Vice Versa?

- Can You use a 15A Outlet on a 20A Circuit and Vice Versa?

- Ground Terminal Up or Down: Which Way Should Outlets Face?

- What Do the Green Dot or Orange Triangle Outlets Mean?

- What Do the Different Colors of Electrical Outlets Indicate?

- Why are Outlets and Receptacles in Hospitals Upside Down?

- How to Size a Load Center, Panelboards and Distribution Board?

- How to Determine the Number of Circuit Breakers in a Panelboard?

- How to Find the Proper Size of Circuit Breaker? Breaker Size Calculator & Examples

- How to Find The Suitable Size of Cable & Wire for Electrical Wiring Installation?

- Why is the Neutral Prong or Slot Wider on a Plug or Outlet?

- What Will Happen If You Connect a Male-to-Male Plug Between Outlets

Related Wiring Tutorials

NEMA Family Outlets/Receptacle Wiring

NEMA 5 -Series

- How to Wire a 15A – 120V Outlet – NEMA 5-15 Receptacle

- How to Wire a 20A – 120V Outlet – NEMA 5-20 Receptacle

- How to Wire a 30A – 120V Outlet – NEMA 5-30 Receptacle

- How to Wire a 50A – 120V Outlet – NEMA 5-50 Receptacle

NEMA 6-Series

- How to Wire a 15A – 240V Outlet – NEMA 6-15 Receptacle

- How to Wire a 20A – 240V Outlet – NEMA 6-20 Receptacle

- How to Wire a 30A – 240V Outlet – NEMA 6-30 Receptacle

- How to Wire a 50A – 240V Outlet – NEMA 6-50 Receptacle

NEMA 10-Series

- How to Replace a 20A – 120/240V Outlet – NEMA 10-20R?

- How to Replace a 30A – 120/240V Outlet – NEMA 10-30R?

- How to Replace a 50A – 120/240V Outlet – NEMA 10-50R?

NEMA 14-Series

- How to Wire a 20A – 125/250V Outlet – NEMA 14-20 Receptacle

- How to Wire a 30A – 125/250V Outlet – NEMA 14-30 Receptacle

- How to Wire a 50A – 125/250V Outlet – NEMA 14-50 Receptacle

- How to Wire a 60A – 125/250V Outlet – NEMA 14-60 Receptacle

NEMA General Outlets/Receptacle

- How to Replace a 15A – 125V, 2-Wire, Non-Grounding NEMA 1-15 Receptacle

- How to Replace a 20A, 2-Wire, Non-Grounding NEMA 2-20 Receptacle

- How to Wire a 30A – 125V Outlet – NEMA TT-30 Receptacle

Good to Know: Although NEMA 2-15, NEMA 2-30, and NEMA 14-15 are officially recognized receptacle configurations, they are not manufactured, commercially available, or used in any standard electrical installations.

General Wiring Installations:

- How to Wire an Outlet Receptacle? Socket Outlet Wiring Diagrams

- How to a Wire 3-Way Combination Switch and Grounded Outlet?

- How to Wire Combo Switch and Outlet? – Switch/Outlet Combo Wiring Diagrams

- How to Wire 120V & 240V Main Panel? Breaker Box Installation

- How to Wire a Subpanel? Main Lug Installation for 120V/240V

- How to Wire 277V & 480V, 1-Phase & 3-Phase, Commercial Main Service Panel?

- How to Wire 240V Water Heater Thermostat – Non-Continuous?

- How to Wire 3-Phase Simultaneous Water Heater Thermostat?

- How to Wire Twin Timer for 120V/240V Circuits – ON/OFF Delay

- How to Wire ST01 Timer with Relay & Contactor for 120V/240V Motors?

- How to Wire Multifunction ON/OFF Delay Timer for 120V/240V Motors?

Switches Wiring

- How to Wire Single Pole, Single Throw (SPST) as 2-Way Switch?

- How to Wire Single Pole, Double Throw (SPDT) as 3-Way Switch?

- How to Wire Double Pole, Single Throw Switch? Wiring DPST

- How to Wire Double Pole, Double Throw Switch? Wiring DPDT

- How to Wire Double Switch? 2-Gang, 1-Way Switch – IEC & NEC

- How to Wire 4-Way Switch (NEC) or Intermediate Switch as 3-Way (IEC)?

GFCI/AFCI Breaker/Outlet Wiring

- How to Wire a GFCI Circuit Breaker?

- How to wire a GFCI Outlet?

- How to Wire GFCI Combo Switch and Outlet – GFCI Switch/Outlet

- How to Wire an AFCI Breaker?

- How to Wire an AFCI Outlet?

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel

How to Wire a 3-Phase, 3-Pole GFCI Breaker in a 3-Φ Panel How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Two-Pole GFCI Breaker in a 120/240V Panel How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel

How to Wire a Single-Pole GFCI Breaker in a 120/240V Panel How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel

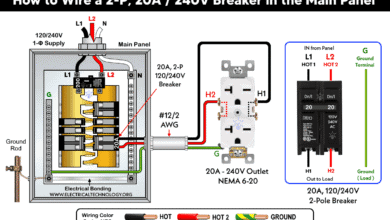

How to Wire a 3-Phase, 3-Pole Breaker in a Three-Phase Panel How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel

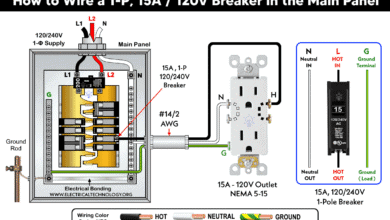

How to Wire a Two-Pole Circuit Breaker in a 120/240V Panel How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel

How to Wire a Single-Pole Circuit Breaker in a 120/240V Panel