What is a Tactile Sensor? Working, Types and Applications

Tactile Sensor – Construction, Working, Types and Applications

Tactile sensor is most commonly used by us in our day to day activities. A number of day to day activities like touch screens of mobile phones, biometric security systems, pressure measurement, force measurement, robotics and many more use this sensor.

What is a Tactile Sensor?

A Tactile sensor is nothing but a touch sensor. It provides information about the object which has made contact with the sensor. The information can be in the form of the shape of the object, size of the object or even the type of the material. This sensor is sensitive to the touch, pressure or any force on its surface. This sensor is commonly sensing the above mentioned characteristics in the form of electrical parameters like capacitance or resistance. Then after further processing a virtual image is created for the above mentioned characteristics. This is done by using other circuits which we call associated circuits also.

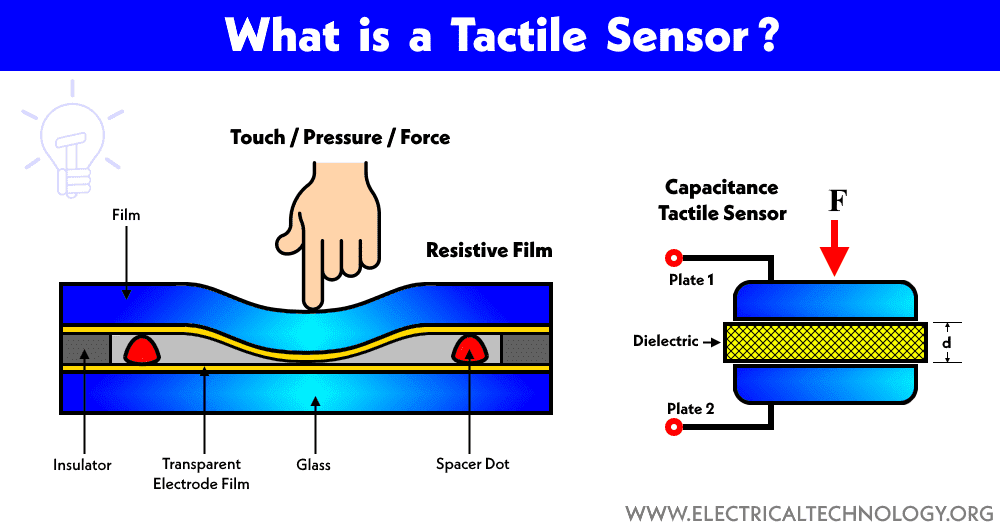

Construction of a Tactile Sensor

Tactile sensor consists of basic electronics components like capacitors, piezoresistors or optical light source and optical light detectors. Use of above mentioned components depends on the type of the sensor which is being used. These basic electronics components are used in large numbers to form one sensor. These basic electronic components are laid in the form of arrays like several rows and columns. Then an associated circuit is used in conjunction with these basic electronic components for further processing of the data which is captured by capacitor, piezoresistors or optical light source and optical light detector.

How does a Tactile Sensor work?

Tactile sensors work on the basic principles of electronics like capacitance change, resistivity change and change in intensity of light due to foreign body interference. The change in capacitance, resistance or light intensity is detected by the use of this sensor. Then this change is used to form a virtual image. The virtual image contains information like how much pressure is exerted from foreign body interference on all points it has made contact with the sensor, how is the shape of the foreign body, what is the size of the foreign body. If you are confused by these statements then simply think of a fingerprint sensor. It can also be called a type of tactile sensor.

Fingerprint sensor scans our finger which is a foreign body for this sensor. It then creates a virtual image by using the sensor and associated circuits in the mobile phone or a special purpose fingerprint sensor.

For sensing the foreign body interference, an array or say multiple rows and columns containing the basic components is used. The foreign body makes contact with these components. Now after contact, there is change in electrical parameters which is input for the associated circuits. The associated circuits then create a virtual image as shown for a fingerprint sensor output. Creation of this kind of virtual image or getting data from the foreign body is the primary purpose of the sensor.

Types of Tactile Sensors

As discussed there are different types based on the components required to construct them. Three main types of tactile sensors are :

- Capacitive Tactile Sensor

- Piezoresistive Tactile Sensor

- Optical Tactile Sensor

Let us have a detailed look on working of different types

Capacitive Tactile Sensor

Capacitive tactile sensor (as shown in the above fig) is one of the most famous amongst all the sensors available today in the market. Change in capacitance is used to detect the touch, pressure or force being measured. Change in touch, pressure or force creates a change in distance between the capacitor plates. Now as any of the mentioned quantity changes, there is change observed in the distance between the capacitor plates which creates change in capacitance change.

C = ε0 × εr × (A ÷ d)

Where

- C = Capacitance of the plate

- ε0 = Free space permittivity

- εr = Relative permittivity

- A = Area of the plates

- d = Distance between the two plates

Here, the area as well as both free space permittivity and relative permittivity remains constant. Only distance between the capacitor plates change when any pressure, force or touch is there on the sensor surface.

An array of capacitors is used to make a capacitive tactile sensor which is shown in the figure. Each capacitor is identified by a distinct location on rows and columns.

Whenever any touch, pressure or force is sensed by a capacitor via change in capacitance, the associated circuit with the capacitive tactile sensor identifies the location of the capacitor. Now by further processing, a virtual image for this touch, pressure or force on the surface is created using these associated circuits and further processing is done. The associated circuit varies depending upon the end user requirements. The response of this sensor is a bit slow compared to other sensors available today.

Related Posts:

- Capacitive Sensor and Transducer and Its Applications

- Resistive Sensors – Transducer, Potentiometer & Strain Gauge

Piezoresistive Tactile Sensor

Piezoresistive tactile sensor is also similar to that of a capacitive tactile sensor. This sensor is the most widely used sensor. This sensor is preferred over capacitive tactile sensor because this sensor has a higher sensitivity compared to capacitive tactile sensor. In this sensor piezoresistive sensors are used. These sensors produce change in their resistance when given any external pressure or external force. This sensor has a series of piezoresistors in many rows and a series of piezoresistors in many columns.

These rows and columns of piezoresistors form a grid-like structure as shown in the figure. Any change in resistance of any piezoresistors is sensed by the associated circuits. The exact location of the piezoresistors which have undergone resistance change is identified by this associated circuit. A virtual image for any touch, pressure or force on the surface is created by this associated circuit. An added advantage for using this piezoresistive tactile sensor is that the hysteresis for piezoresistive sensors is very low.

This sensor is made up of materials such as conductive rubber, carbon fibers and other specially developed conductors.

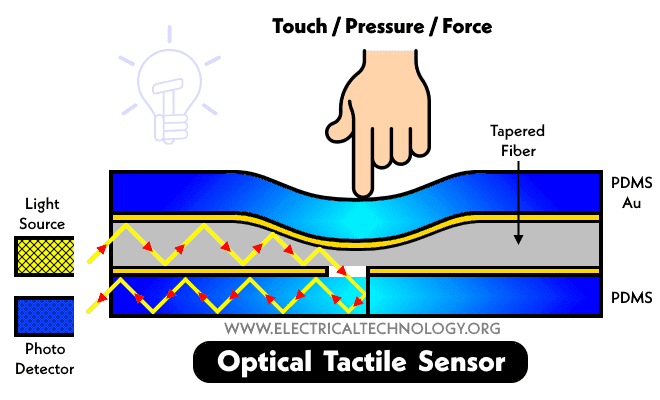

Optical Tactile Sensor

Optical tactile sensor works on the changing intensity of light. In this sensor, change in intensity of light due to touch, pressure or force is measured. A light source is constantly sending light to the light detector placed on the opposite end. Whenever any area in between these light sources and light detector undergoes shape change due to touch, pressure or force on the surface, change in intensity of light is observed. Several such pairs of light source and light detector are used in an optical tactile sensor. This change in intensity of the light received by the detector is shown or virtually plotted as an image using special circuits. The image shows how the light intensity changes due to deflection when any external force is applied on the sensor surface.

The resolution and sensitivity of this sensor is a bit lower than that of the piezoresistive tactile sensor. But the relative cost which is lower than other types of sensors is an added advantage for this sensor. This sensor is mainly used in robotics and advanced research.

Applications of Tactile Sensors

Tactile sensors are widely used in following areas:

- Mobile phones

- Capturing biometric data

- Pressure measurement

- Force measurement

- Home automation and security

- Automobile security

- Advanced medical devices

- Communication and research

- Modern robotics

Related Posts:

- Main Difference Between Sensor and Actuator

- Main Difference between Sensor and Transducer

- Automated Fingerprint Identification System and How it Works?

- Voice Recognition Based Home Automation System