Difference Between Porcelain and Glass Insulators

Key Differences Between Glass and Porcelain Insulators

Both porcelain and glass insulators are widely used in power transmission and distribution to insulate the overhead line conductors from the support towers and poles. Both have a good life span and are used for high voltage ratings. There are some specific characteristics and properties which distinguish both of them for different applications.

Porcelain Insulator

Porcelain is a ceramic material and a good ceramic is free of internal densities, holes and cracks formation without thermal expansion.

A porcelain is made of china clay which is naturally available as Aluminum Silicate. The mixture of plastic cauline, feldspar (crystal stone of silica), and quartz (Silicon Dioxide “SiO2” are heated up in the kiln furnace at controlled temperature to make a smooth, tough and shiny insulator without porous.

A strong porcelain insulator has a dielectric strength of 60kV/cm, compressive strength of 70,000 kg/cm2 and tensile strength about 500 kg/cm2.

Cement is used as bonding material to make the porcelain insulators which is one of the most popular types of insulators used widely around the world in power transmission and destruction networks.

Related Posts:

- Corona Effect & Discharge in Transmission Lines & Power System

- Overhead Lines Protection – Faults and Protection Devices

Glass Insulator

Toughened glass is used to make these kinds of insulators. The glass material is heated up and after the melt and cool bath, it offers a very high dielectric strength up to 140kV/cm.

The toughened glass suspension insulators are widely used for high voltage transmission (≥ 500 kV) around the world. They have very high resistivity and one of the most advantages is that the faulty or sparked insulator can be easily detected and spotted due to the transparent design.

Glass insulators offers a compressive strength and tensile strength of 10,000kg/cm2 and 35,000kg/cm2 respectively.

Related Posts:

- Electrical Transmission Networks – EHV and HV Overhead Lines

- Busbars and Connectors in HV and EHV installations

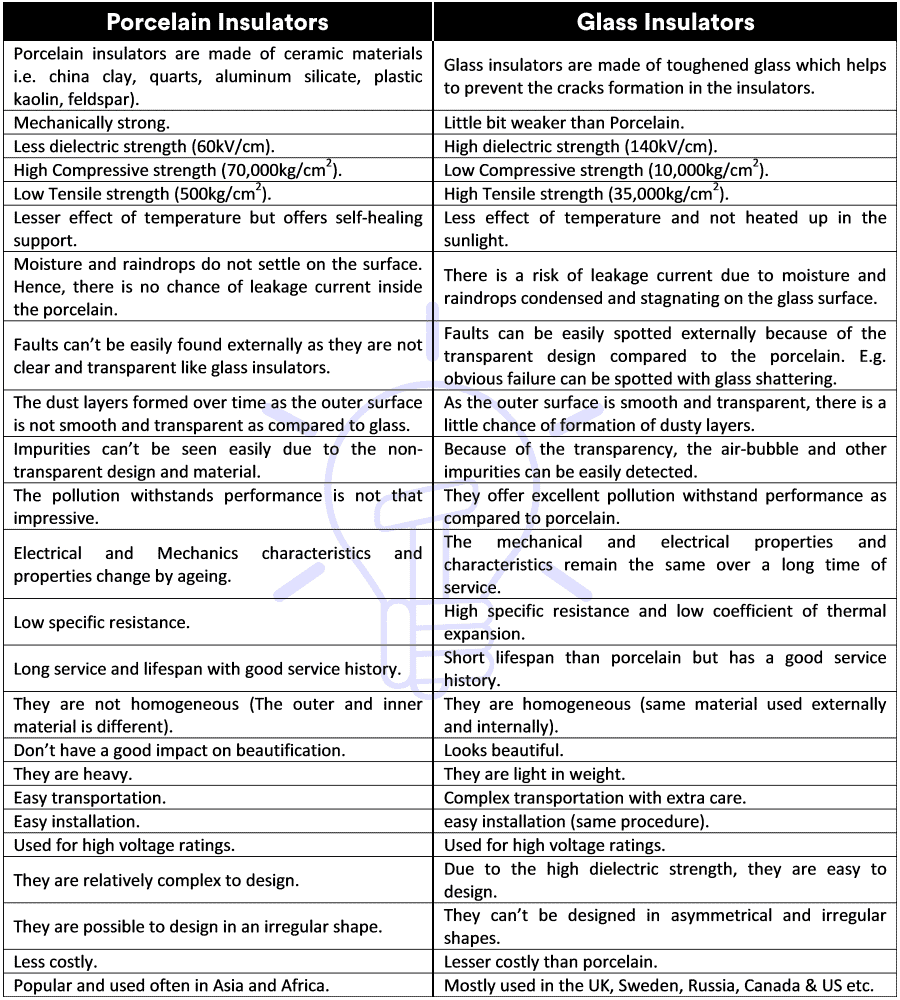

Comparison Between Glass and Porcelain Insulators.

The following comparable table shows the main features, characteristic and properties of both porcelain insulators and glass insulators which shows the key differences between them.

| Porcelain Insulators | Glass Insulators |

| Porcelain insulators are made of ceramic materials i.e. china clay, quarts, aluminum silicate, plastic kaolin, feldspar). | Glass insulators are made of toughened glass which helps to prevent the cracks formation in the insulators. |

| Mechanically strong. | Little bit weaker than Porcelain. |

| Less dielectric strength (60kV/cm). | High dielectric strength (140kV/cm). |

| High Compressive strength (70,000kg/cm2). | Low Compressive strength (10,000kg/cm2). |

| Low Tensile strength (500kg/cm2). | High Tensile strength (35,000kg/cm2). |

| Lesser effect of temperature but offers self-healing support. | Less effect of temperature and not heated up in the sunlight. |

| Moisture and raindrops do not settle on the surface. Hence, there is no chance of leakage current inside the porcelain. | There is a risk of leakage current due to moisture and raindrops condensed and stagnating on the glass surface. |

| Faults can’t be easily found externally as they are not clear and transparent like glass insulators. | Faults can be easily spotted externally because of the transparent design compared to the porcelain. E.g. obvious failure can be spotted with glass shattering. |

| The dust layers formed over time as the outer surface is not smooth and transparent as compared to glass. | As the outer surface is smooth and transparent, there is a little chance of formation of dusty layers. |

| Impurities can’t be seen easily due to the non-transparent design and material. | Because of the transparency, the air-bubble and other impurities can be easily detected. |

| The pollution withstands performance is not that impressive. | They offer excellent pollution withstand performance as compared to porcelain. |

| Electrical and Mechanics characteristics and properties change by ageing. | The mechanical and electrical properties and characteristics remain the same over a long time of service. |

| Low specific resistance. | High specific resistance and low coefficient of thermal expansion. |

| Long service and lifespan with good service history. | Short lifespan than porcelain but has a good service history. |

| They are not homogeneous (The outer and inner material is different). | They are homogeneous (same material used externally and internally). |

| Don’t have a good impact on beautification. | Looks beautiful. |

| They are heavy. | They are light in weight. |

| Easy transportation. | Complex transportation with extra care. |

| Easy installation. | easy installation (same procedure). |

| Used for high voltage ratings. | Used for high voltage ratings. |

| They are relatively complex to design. | Due to the high dielectric strength, they are easy to design. |

| They are possible to design in an irregular shape. | They can’t be designed in asymmetrical and irregular shapes. |

| Less costly. | Lesser costly than porcelain. |

| Popular and used often in Asia and Africa. | Mostly used in the UK, Sweden, Russia, Canada & US etc. |

The above tables can be downloaded in the image format for reference as below:

Click image to enlarge

Related Posts:

- Difference between AC and DC Transmission System & Power Lines

- Difference between Lightning Arrester and Surge Arrester

- Differences Between HVAC and HVDC – Power Transmission

- Difference between Stranded Wire vs Solid Wire

- Difference Between Current Transformer & Potential Transformer

- Difference Between Single Phase and Three Phase Power Supply

- Difference Between Grounding, Earthing and Bonding

- Difference Between Neutral, Ground and Earth?

- Difference between Star and Delta Connections – Comparison Of Y/Δ

- Difference between Circuit Breaker and Isolator / Disconnector

- Difference Between Power Transformers and Distribution Transformers?