Difference Between Squirrel Cage and Slip Ring (Wound) Rotor

Difference Between Squirrel Cage Rotor & Wound Rotor (Slip Ring) Motors

Among the different types of electric motors, squirrel cage and wound rotor motors are widely used. Both motor types have distinct designs and characteristics that make them suitable for specific applications. This article explores the differences between squirrel cage and wound rotor (slip ring) motors, highlighting their construction, operation, advantages, and applications.

- Related Post: Difference Between Servo Motor and Stepper Motor

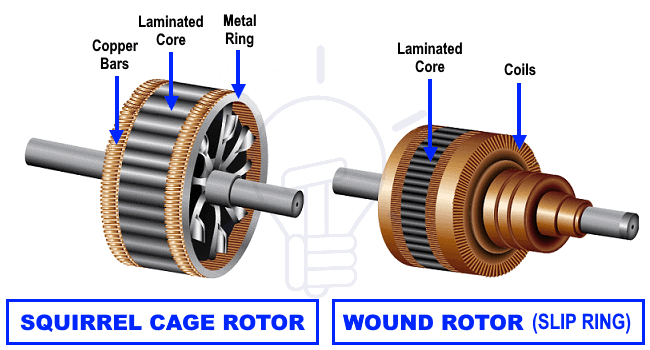

Squirrel Cage Rotor

A squirrel cage rotor is a type of rotor used in three-phase and single-phase induction motors. It’s called a “squirrel cage” because of its appearance, which resembles a rotating cage made of bars. The rotor consists of a laminated cylindrical core with conductive bars running along its length. These bars are typically made of aluminum or copper and are short-circuited at each end by end rings.

When an alternating current (AC) is applied to the stator windings of an induction motor, it produces a rotating magnetic field. This rotating magnetic field induces a current in the rotor bars due to electromagnetic induction. The interaction between the rotating magnetic field and the current in the rotor bars produces a torque, which causes the rotor to rotate.

The squirrel cage rotor is widely used in induction motors because it is simple, rugged, and requires no electrical connection to the rotor. It is also known for its high starting torque and efficiency.

- Related Post: Difference Between Brushed and Brushless Motor

Wound Rotor (Slip Ring)

A wound rotor, also known as a phase wound or slip ring rotor, is another type of rotor used in 1-phase and 3-phase induction motors. Unlike the squirrel cage rotor, the wound rotor has a winding of wire around its core, similar to the stator windings. The ends of the rotor winding are connected to slip rings, which are metal rings mounted on the rotor shaft and insulated from it. Carbon brushes are used to make electrical contact with the slip rings.

The slip rings allow external resistance to be connected to the rotor winding. This external resistance can be varied to control the speed-torque characteristics of the motor. By increasing the resistance, the starting torque can be increased, and the speed can be controlled over a wider range.

Wound rotor motors are often used in applications where the speed needs to be controlled, such as in cranes, hoists, and large fans. They offer greater control over the motor’s performance compared to squirrel cage motors but are more complex and require additional maintenance due to the slip rings and brushes.

- Related Post: Difference between Synchronous and Asynchronous Motor

Comparison Between Squirrel Cage Rotor & Wound Rotor (Slip Ring)

Here’s a comparison table between Squirrel Cage and Slip Ring (Wound) Rotor.

| Feature | Squirrel Cage Rotor | Wound Rotor (Slip Ring) |

| Construction | Construction is simple. It Consists of solid, conducting bars or rods embedded in the slots of the rotor laminations, resembling a squirrel cage. | Construction is complicated. It Consists of a laminated core with a three-phase winding similar to that of a stator winding, with the rotor winding brought out to slip rings and brushes for external connection. |

| Rotor/Stator | Heavy bars made of copper, aluminum, or alloy are used as conductors over a cylindrical laminated core in the rotor. | The cylindrical rotor has layers of metal sheets (laminations) and is wound with wire based on the number of poles in the stator. |

| End/Slip Rings | Rotor bars (rotor conductors) are short-circuited with the end rings. | The three-phase windings are connected to a rheostat in star configuration during starting. The 3-phase windings are short-circuited at the slip rings during running conditions. |

| Starting Torque | Lower starting torque compared to wound rotor motors. | Higher starting torque due to the external resistance that can be added to the rotor winding. |

| External Resistance | It is not possible to connect external resistance in series with the rotor circuit because the rotor bars are permanently short-circuited. | It is possible to insert an external resistance in the series of the rotor circuit to start the motor as well as increase the torque. |

| Speed Control | Speed control using rotor resistance is not possible as the rotor bars are short-circuited. | Easier speed control by varying the external resistance connected to the rotor winding. |

| Moving Contacts | There are no moving contacts in the rotor circuit. | Slip rings and Carbon brushes are provided in the rotor circuit. |

| Starting Current | The starting current is 5 to 7 times the full-load current. | Less starting current is needed to start the motor compared to squirrel cage motor. |

| Efficiency | Higher efficiency under normal operating conditions. | Lower efficiency due to the additional losses in the external resistors and brushes. |

| Maintenance | Virtually maintenance-free as there are no brushes or slip rings. | Requires periodic maintenance of slip rings and brushes. |

| Cost | Generally lower cost due to simpler construction. | Higher cost due to the additional components and maintenance requirements. |

| Applications | Commonly used in applications where constant speed is required, such as fans, blowers, and pumps. | Often used in applications where high starting torque and speed control are important, such as cranes, hoists, and elevators. |

Difference Between Squirrel Cage and Slip Ring (Wound Rotor) Motors

1. Construction:

- Squirrel Cage Motor: The squirrel cage motor gets its name from its rotor design, which resembles a squirrel cage. The rotor consists of copper or aluminum bars placed in slots on the rotor laminations. These bars are short-circuited at both ends by end rings, forming a closed-loop circuit. The rotor assembly is placed inside the stator, which contains the motor’s windings.

- Wound Rotor Motor: In contrast, the wound rotor motor has a rotor with windings similar to those found in the stator. The rotor windings are connected to slip rings on the rotor shaft. Carbon brushes are used to make electrical contact with the slip rings, allowing external resistance to be connected to the rotor windings.

2. Operation:

- Squirrel Cage Motor: When an AC voltage is applied to the stator windings, a rotating magnetic field is produced, which induces currents in the rotor bars. These currents create a magnetic field in the rotor, which interacts with the stator’s magnetic field, producing torque that drives the motor.

- Wound Rotor Motor: The wound rotor motor operates similarly to the squirrel cage motor, but with an added variable resistance feature. By varying the resistance connected to the rotor windings through the slip rings, the speed-torque characteristics of the motor can be controlled. This feature makes wound rotor motors suitable for applications that require adjustable speed and high starting torque.

3. Advantages:

Squirrel Cage Motor:

- Simple construction, leading to lower cost and maintenance requirements.

- High efficiency and reliability.

- Suitable for applications with constant speed requirements.

Wound Rotor Motor:

- High starting torque, making them suitable for applications with high starting loads.

- Adjustable speed-torque characteristics.

- Lower starting current compared to squirrel cage motors.

4. Disadvantages:

Squirrel Cage Motor:

- Limited speed control capabilities.

- Less suitable for applications requiring variable speed operation.

Wound Rotor Motor:

- Higher initial cost due to the complexity of the rotor windings and slip ring assembly.

- Higher maintenance requirements due to the use of slip rings and brushes.

Related Posts:

- Difference Between Single Phase & Three Phase Induction Motor

- Difference Between AC and DC Motors

- Difference Between AC and DC Generator

- Difference Between a Transformer and an Induction Motor

- Difference Between Alternator and Generator

- Difference between AC Drives and DC Drives

- Alternator or Synchronous Generator: Construction, Working, Types and Applications

- Synchronous Motor: Construction, Working, Types & Applications

- DC Machine – Construction, Working, Types and Applications

- Speed Control of DC Motor – Voltage, Rheostatic & Flux Control Methods

- Cable Size Calculation for LT & HT Motors.

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- Three Phase Motor Power & Control Wiring Diagrams

- Electric Motors Symbols

- Types of Electric Motors

- Applications of Electric Motors