What is the White Powder on the Circuit Breaker Terminals?

Why Does White Chalky Powder or Paste Form on Circuit Breaker Terminals?

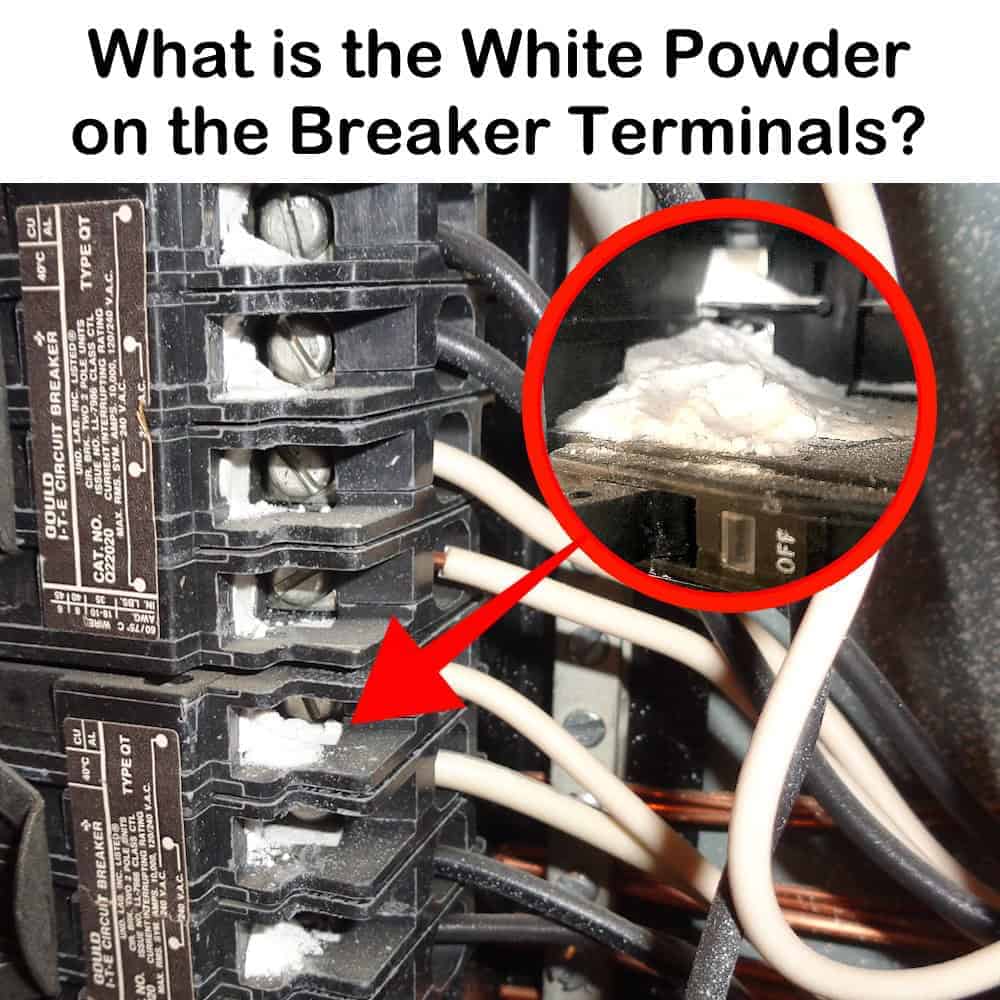

You may have noticed a white powder on circuit breaker terminals, especially in basements or areas with high humidity. Typically, this occurs due to one of two reasons: it may be residue from a factory-applied sealant or lubricant, or it could be a sign of corrosion. If you’re wondering about the formation of this white, chalky powder or paste on circuit breakers, below are the possible causes and preventive measures to avoid serious safety hazards.

Factory Sealant or Lubricant Residue:

Some circuit breaker manufacturers (e.g., Siemens, sometimes Square D) apply a white, chalky, or waxy sealant/potting compound near the screw terminals or internal adjustment points during manufacturing.

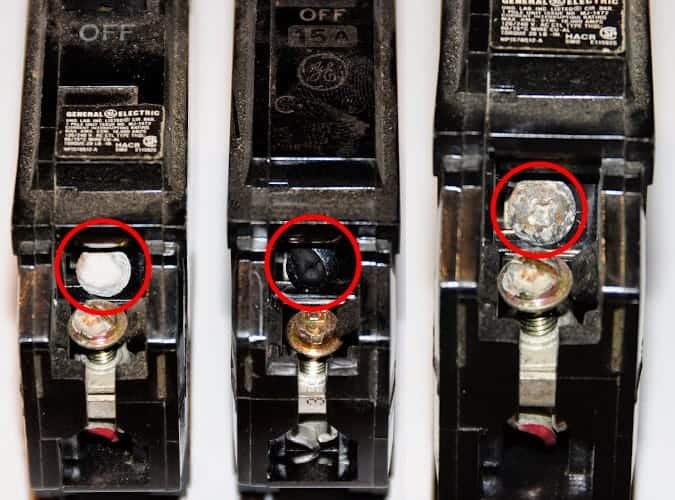

This material is used to provide some level of insulation or seal to prevent tampering with internal calibration screws. If you remove the lubricant or white seal, you will see the tempering screw right below the anti tamper sealant as shown in the fig below.

Over time, especially with heat cycles and age, this sealant can degrade, dry out, and crumble. As a result, white powder or residue oozing from gaps appears in the breaker casing near the terminals.

Is it Dangerous?

Generally, if this is the cause i.e. insulating compound from the factory or dust/debris, and there are no other signs of overheating, arcing, or loose connections, it’s considered harmless cosmetic degradation by some manufacturers and inspectors. However, if there’s a significant amount or it’s accompanied by other concerning signs, it’s always better to be safe.

In such cases, contact the manufacturer’s helpline or a company representative and provide clear images along with detailed information. Replace the faulty breakers with new one if needed.. As a precaution, have the main panel and breakers inspected by a licensed and qualified electrician to ensure safety.

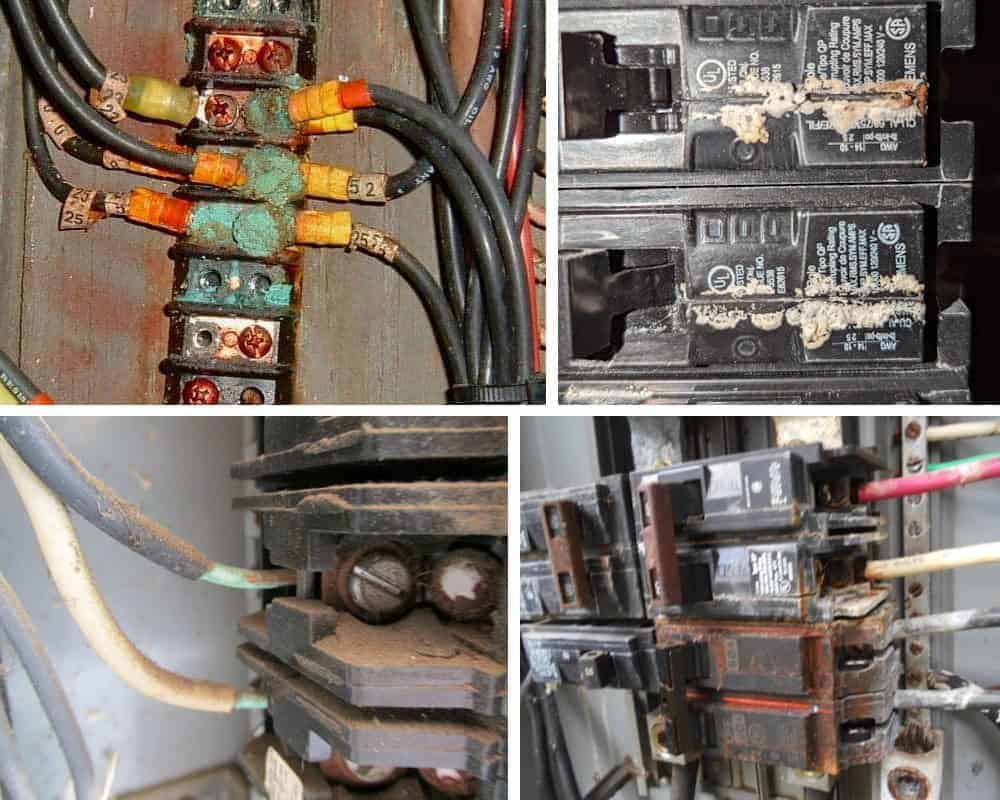

Corrosion

The white powder or paste on breakers terminals are more concerning if due to corrosion. It is usually an oxide of the metal used in the terminals or the wire connected to them.

If there is humidity, nearby water leakage, or high moisture around the breakers, a white or bluish-green substance may appear on the terminals due to heat and moisture penetration. When the breaker heats up during operation and moisture evaporates, dissolved minerals as a solid stuff are left behind on the terminals. This is the same case like automotive connectors and batteries terminals.

It is the similar process like efflorescence or mold, the process where a powdery, often white, deposit appears on the surface of porous materials like concrete or brick. This occurs when water-soluble salts within the material dissolve in water, migrate to the surface, and then precipitate out as the water evaporates. While not typically harmful to the material itself, it can indicate moisture problems within a structure.

Click image or open in a new tab to enlarge

Aluminum Wiring

If your home or panel has aluminum wiring, white powder at the connection points is a very common and serious sign of aluminum oxide. Aluminum oxidizes easily when exposed to air, and aluminum oxide is a poor conductor of electricity. This leads to increased resistance, which generates heat. This cycle of heating, cooling, and expansion/contraction (aluminum expands more than copper) causes connections to loosen further, leading to more aluminum oxidation, more heat, and a significant fire hazard.

Some terminals or screws may have zinc or galvanized coatings. When they corrode, zinc oxide or zinc carbonate (white powder) can form.

Copper Wiring

While copper can also corrode, although it doesn’t rust like iron. Copper corrodes and forms green or bluish-green corrosion (like on old pennies or car battery terminals) when exposed to oxygen and moisture. However, in the presence of certain chemicals or extremely high humidity, or if dissimilar metals are in contact such as galvanic corrosion, it might manifest differently.

Causes of Corrosion:

Moisture/Humidity

Water is a primary culprit. Leaks in the panel, high humidity in basements, or condensation can lead to corrosion. Water can wick along wires or get into the panel from poorly sealed conduits or service entry points.

Loose Connections

A loose connection creates resistance, which generates heat. Heat accelerates oxidation and corrosion.

Dissimilar Metals (Galvanic Corrosion)

When two different metals (e.g., aluminum and copper) are in direct contact in the presence of an electrolyte (like moisture), one metal will corrode at an accelerated rate. This is a major reason why aluminum wiring is problematic at connection points unless specific, approved connectors (CO/ALR devices or special crimps) are used.

Contaminants

Airborne pollutants, chemicals, or even salt (in coastal areas or if road salts are tracked in) can contribute to corrosion.

- Related Post: Ground Pin Up or Down: Which Way Should Outlets Face?

Dangers of Corrosion:

Increased Resistance and Heat

This is the biggest danger. High resistance can cause the breaker, wire, and panel components to overheat, potentially leading to melted insulation, arcing, and fire.

Intermittent Connections

Corrosion can lead to unreliable power, causing lights to flicker or appliances to malfunction.

Breaker Failure

Over time, corrosion can damage the internal mechanisms of the circuit breaker, preventing it from tripping when it should, which eliminates a crucial safety feature.

What to Do if You See White Powder:

This is not something to ignore. White powder on circuit breaker terminals is a red flag especially if caused by corrosion..

- ❌ Do NOT touch it. Turn Off Power: Always isolate the breaker or circuit before inspecting.

- 🛑 Clean the Terminals. Use a non-metallic brush and contact cleaner. Do not use sandpaper or abrasive tools that may damage the plating.

- ✅ Immediately contact a qualified, licensed electrician. They can safely inspect the panel, determine the cause of the white powder, address any corrosion, tighten connections, and replace any damaged components or breakers.

- 🚫 If you suspect water ingress or condensation, identify and fix the source of the moisture.

- 🔁 If the breaker shows signs of burning, pitting, or excessive corrosion, replace it with a new one.

- 📝 Use permanent dehumidifier in basement near the panel. When working with aluminum wires, apply a Noalox or Ox-Gard paste to reduce future oxidation.

- ⚠️ Ignoring corrosion in an electrical panel can lead to serious hazards, including electrical fires and shock.

Related Posts:

-

- Can We Use AC Circuit Breaker for DC Circuit & Vice Versa?

- Why is Earth Pin Thicker and Longer in a 3-Pin Plug?

- What Are the Colored Aerial Marker Balls on Power Lines For?

- What are the Tiny Cylinder in Power Cords & Cable?

- What Happens if a Battery is Connected to the AC Supply?

- What Happens to the Battery with Reverse Polarity Wiring Connection

- What Happens if We Connect a Polar Capacitor the Wrong Way?

- Which One Kills – Current or Voltage and Why? Amps vs. Volts

- AC or DC? Which One is More Dangerous And Why ?

- Why Can’t a 12V Car Battery Electrocute You?

- Will I Get an Electric Shock If I Touch the Ground Wire?

- Why is the Long Prong Neutral Instead of the Narrow Prong?

- Why are there Grooved Slots in the Pins of Two Pin Plugs?

- Why is the Neutral Wire Size Smaller than the Phase Wire?

- Can the Neutral Wire Cause Electric Shock?

- Will a Man Get an Electric Shock If He Hangs on a Live Wire?

Resources of Breakers in Electrical Wiring Installation

- How to Find the Proper Size of Circuit Breaker?

- How to Determine the Number of Circuit Breakers in a Panel Board?

- How to Find the Number of Lights on a Single Circuit Breaker?

- How to Find the Number of Outlets on a Single Circuit Breaker?

- How Does a Standard Breaker Respond to Electrical Fault?

- Why Doesn’t a Standard Breaker Protract Against Ground Faults?

- How Do GFCI and Standard Breakers Respond to Ground Faults?

- What is the Suitable Wire Size for 20A Breaker and Outlet?

- What is the Right Wire Size for 15A Breaker and Outlet?

- How Many Amps Will Flow in a Short Circuit Powered by a 120V, 20A Breaker?

- Difference Between Circuit Breaker and GFCI

- How to Wire a GFCI Circuit Breaker?

- How to Wire 120V & 240V Main Panel? Breaker Box Installation