Electromechanical or Electromagnetic Relay (EMR): Construction, Working, Types and Applications

What is an Electrical Relay?

A relay is an electrically operated automatic switch that switches a pair or more than a pair of contacts by applying an electrical signal. It is used for switching high-power circuits using a low-power signal.

There are several types of electrical relays. Where electromagnetic relay is one type of relay.

Electromagnetic Relay

An electromagnetic relay or EMR (also known as Electromechanical Relay) is a type of electrical relay that is used to switch a circuit by using an electromagnet. The electromagnet produces a magnetic field that causes a force of attraction which results in the mechanical switching of the contacts.

Construction of Electromagnetic Relay

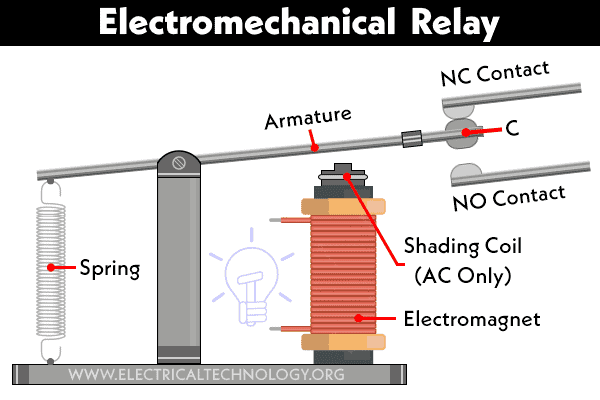

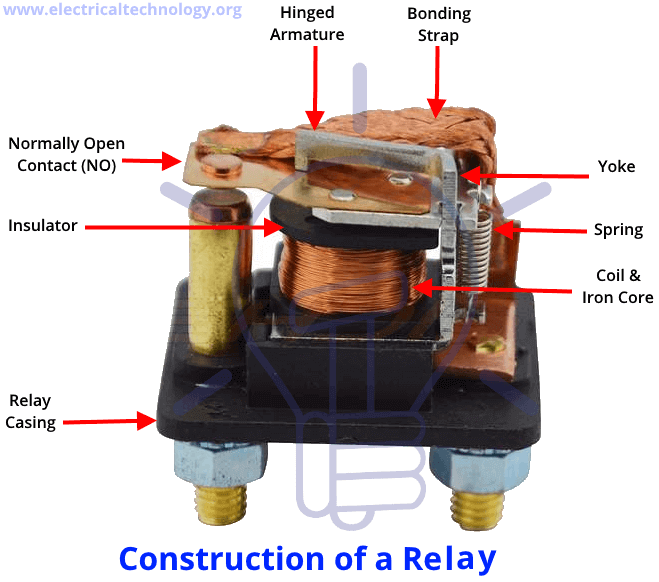

An electromagnetic or electromechanical relay is mainly made of three main components.

- Electromagnetic Coil

- Movable Armature

- Contacts

Electromagnetic Coil

An electromagnet is a wire wound around a core of ferromagnetic material. When the current is passed through the coil, it energies and generates a strong magnetic field around it. The electromagnetic coil is connected to the low-power circuit or supply.

Movable Armature

The movable armature is the conducting part of the relay. It is the common link between the two contacts. Therefore it is used to break or make the connection between it. It is made of metal that is attracted towards the energized electromagnetic coil. Once the coil is de-energized, a spring connected to the other end of the armature pulls it to its original position.

Contacts

The contacts are used to break or make connections in a high-power circuit. It is made of material that is highly conductive and resistant to overheating and arching. The material used for contacts could be silver, Tungsten, Palladium, etc. There are two different types of contacts in a relay i.e. normally closed NC and normally open NO contacts.

The NC contacts are normally closed contacts meaning that these contacts are in closed position when the coil is not energized. While NO contacts are open when the coil is not energized.

The armature contact switches between the NC and NO contacts depending on the coil supply.

Working of Electromagnetic Relay

The EMR relay works on the principle of electromagnetic attraction between the coil and the armature. There are two states or conditions in EMR relay i.e. Energized State and de-energized state.

The EMR relay has an electromagnetic coil that energizes using a small signal called a control signal. Once the coil is energized, the coil produces a magnetic field around it. The Magnetic field applies a force of attraction on the armature and pulls it down. When the control signal is removed, the coil de-energizes and the magnetic field vanishes. Therefore, the force of attraction acting on the armature also vanishes. The spring connected at the other end of the armature pulls the armature into its normal position.

In a de-energized state, the common contact is connected with the NC terminal. While in an energized state, the common contact switches from the NC terminal to the NO terminal.

Specification of Relay

There are different types of relays available in the market whose performance depends on certain specifications.

Coil Ratings

It is the input voltage and current of the control signal required to energize the coil. It is different for AC and DC coils.

DC Resistance

It refers to the DC resistance of the electromagnetic coil in the relay.

Contact Ratings

The contact ratings show the maximum voltage and current the contacts can handle continuously.

Switching Time

Switching time refers to the switch-on and switch-off time. The time taken by the relay to switch the contacts after energizing is called switch-on time. The time taken by the relay to switch the contacts after de-energizing is called switch-off time.

The switching time is very important for relays that are used in sensitive and expensive equipment. It is also crucial in protection relay.

Enclosure

There are certain relays with enclosures. It helps in protecting the relay from dust particles gathering between the contacts. It can also isolate the arc from creating fire hazards. Therefore, in open circuits or hazardous environments, enclosed relays must be used. However, you may use open-type relays in closed devices.

Related Post:

- Difference Between Solid-State Relay and Electromechanical Relay

- Difference Between Relay and Circuit Breaker

Types of Electromagnetic Relay

There are different types of electromagnetic relays classified based on different parameters.

Based on Construction and Operation

Based on operation, EMR is classified into two types

- Electromagnetic Attraction Relay

- Electromagnetic Induction Relay

Electromagnetic Attraction Relay

Such type of relay is the most commonly used and simple EMR relay. In such a relay, the armature is attracted toward the electromagnet. It works on both AC and DC supplies.

The electromagnetic coil is used to produce a magnetic field that attracts the armature. The magnitude of the attracting force is directly proportional to the square of the flux or supply current. Since the DC is constant, the force generated is also constant. Whereas in AC relay, the electromagnetic force generated pulsates at double the supply frequency. This pulsating magnetic force produces noise and causes damage to the contacts.

Balanced Beam Relay

Balanced beam relay is a type of electromagnetic attraction relay. It is used to compare two quantities. It is made of a horizontal beam supported by a pivot in the middle. There are two sets of contacts at the end of the beam. There are two coils below the beam i.e. operating coil and restraining coil. These two coils produce torque in the beam that is opposite in direction of each other. Thus the torque cancels out each other and the beam remains in the normal position.

The net torque generated in the beam is the difference between the two torques. Since the torque is generated due to the magnetic force of attraction which is directly proportional to the current. The net torque depends on the difference between the two signals. Thus it compares the two signals at electromagnetic coils. If the operating torque is greater than the restraining torque, the beam pulls the contact into the closed state. When the restraining torque exceeds the operating torque, the beam pulls back and opens the contacts.

Such type of relay was used in the past as differential Relay and impedance relay. It has now been replaced by modern devices such as rectifier bridge comparator, and moving coil relay.

The advantage of beam type relay is that it can be adjusted for fast operation. The main disadvantage is the poor reset/operate ratio and phase displacement

Hinged Armature Relay

This is another type of most commonly used armature attraction relay. The armature is connected at one end using hinges to the core of the electromagnet and contacts at the other end. The force of attraction is directly proportional to the square of flux in the air gap between the armature and the pole. Since the air gap decreases as the armature approaches the pole, the force increases.

The hinged armature-type relay operates on both AC and DC. In DC, the force of attraction is constant while in AC, it pulsates at double the supply frequency. Another coil is added called the restraining coil which is energized by a phase-shifting circuit. It helps in restoring the armature to its normal position.

The armature attraction relay is mainly used for the protection of machines and equipment. It is an instantaneous relay with a very high operating speed of about 5 ms.

Plunger Type

In such type of relay, there is a solenoid with an iron plunger that goes through it. Contacts are placed at one end of the plunger with a spring that applies the restraining force on the plunger. The coil/solenoid once energized, pulls the plunger closing the contacts. When the supply is revived, the solenoid de-energizes and the plunger is no longer attracted. The spring pulls out the plunger thus breaking the contact.

Plunger-type attraction relays are no longer being used since it has been replaced by more efficient and fast-switching relays.

Moving Coil Relay

A moving coil relay is another type of attraction relay where a moving coil is placed inside a permanent magnet. The coil carries the moving contact that closes and breaks when the coil moves. It is also called a polarized DC moving coil relay. It operates only in DC. A proper rectifier can be used with AC. It is the most sensitive electromagnetic relay. Due to its high sensitivity, it is used for accurate measurement of distance and differential protection.

There are two types of moving coil relay

- Rotary moving coil relay

- Axial moving coil relay

Rotary Moving Coil Relay

The given figure shows a rotary moving coil relay. There is a premature magnet with a coil wound on an iron core. A spiral spring provides the resetting torque. The coil carries an arm having contact.

When the current passes through the coil lying inside the magnetic field, it rotates. The rotation is due to the interaction between the magnetic field of the permanent magnet and the coil. The arm also rotates and closes the contacts. The spiral spring provides the resetting torque that increases with the rotation of the coil.

Axial Moving Coil Relay

In the axial moving coil relay, the given figure shows the structure of the axial moving coil relay. The coil is wounded on a cylindrical core and suspended horizontally. It rotates along its axis.

These kind of relays are faster and more sensitive than the rotary type. In short, It is a very sensitive relay with a very small contact gap.

Reed Relay

The reed relay consists of a hermetically sealed glass tube with a strip of nickel-iron inside it. A coil surrounds the glass tube. The thin strip is fixed at one end and free at the center of the tube. The free ends of the strip after as contacts of the relay as shown in the figure down below.

When the coil is energized, it produces a magnetic field that generates a force of attraction between the strips and closes the contact. Since the reed switch (strip contacts) is hermetically sealed, there are no arching and dust gathering between the contacts. Therefore, reed relays are maintenance-free and reliable.

Reed relays are electromagnetic relays based on is design. Whereas operation-wise, they are static relays. They are used for protection. There are no vibrations during its operation

Polarized Moving Iron Relay

In such a relay, the coil is stationary which attracts the arm to break or make contact. It uses a permanent magnet for polarization and creates flux in addition to the flux of the coil. A permanent magnet is used for polarization which increases the sensitivity of the coil. It is a DC-operated relay. However, AC can be used with a rectifier.

A polarized moving coil relay operates when the supplied DC is of the correct polarity. It will not operate on reverse polarity. Other attracted armature-type relays do not depend on input polarity. Since the coil is stationary, the relay is comparatively more reliable and robust.

Related Posts:

- How to Test a Relay? Checking SSR and Coil Relays

- Electronic Relay Switch Circuit – NPN, PNP, N and P Channel Relay Switches

Electromagnetic Induction Relay

The electromagnetic induction type relay works on the principle of electromagnetic induction same as in a single-phase induction motor. The movement is developed by the interaction between the flux generated in the coil and the flux generated due to the Eddy current in the non-magnetic rotor.

Since it operates on electromagnetic induction, it works only on AC.

Induction Disc Relay

In an induction Disc relay, there is a rotating aluminum or copper disc that is used for making and breaking the contacts. The torque produced in the rotating disc is due to the flux of the AC electromagnet.

The disc is placed between the two poles of an electromagnet that produces an alternating flux. This flux produces an Eddy current in the disc that is in phase with the flux, thus no torque will be produced.

To generate torque in the rotor, we have to provide rotating flux or phase-shifted flux. Therefore, the induction disc type is further divided into two types.

Shaded Pole Structure

In a shaded pole structure, the pole of the electromagnet is divided into two equal portions. One-half of the portion is covered with shaded copper rings while the other remains unshaded as shown in the figure below.

The unshaded portion produces a flux that will induce a current in the shade ring causing to produce another flux having a different phase. These two fluxes induce Eddy current with respective phases in the disc. The flux interacts with the Eddy current of each other and produces net torque in the disc.

Related Posts:

- Types of Circuit Breakers – Working and Applications

- Types of Switches. Its Construction, Working and Applications

Watt-hour Meter Structure

In such a disc type of relay, two electromagnets are used with a free-rotating disc between them. The two electromagnets, the upper E-shaped carry two windings on its central line and the lower U-shaped electromagnet carries the secondary winding on both limbs. These two windings produce an alternating flux that has a phase difference depending on the displacement between the windings. The two different fluxes induce Eddy current in the disc that interacts with each other generating net torque.

In order to break the contact, resetting torque must be produced. Therefore, a spiral spring is used to provide the resetting torque. The advantage of a disc-type induction relay is that its current and time settings can be easily adjusted according to the application. They are robust and accurate in providing protection.

Induction Cup Relay

The induction cup relay is a modified form of induction disc relay where a rotating hollow cup is used instead of a disc. The small inertia of the cup allows it to have a very high-speed operation. It can have several pole counts which are proportional to the torque generated. A hollow cup that has a stationary iron core placed inside of it, is surrounded by four stationary windings carrying two pairs of coils. Each pair produces opposite poles. The cup carries an arm that makes or breaks the contacts. A spring is used to provide the restraining torque.

When the windings are energized, they produce a rotating magnetic field that induces current in the cup. The rotating magnetic flux interacts with the induced current and produces a torque in the cup. The arm rotates to switch the contacts.

The hollow cup design provides low resistance for induced current. Its small weight and better magnetic circuit make it 3 times more efficient than disc type relay.

Based on Contacts

Relays can be classified based on the configuration of the contacts.

Single-Pole Single-Throw (SPST)

Single pole single throw or SPST relay has only one pole meaning it can control only one circuit and the single throw means its pole can conduct in only one position. The SPST diagram is given below.

It has four terminals; two for energizing the coil(input signal), and two for the control circuit. It has only two states I.e. open or close state.

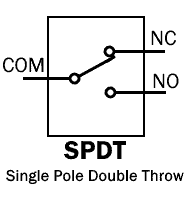

Single-Pole Double-Throw (SPDT)

The SPDT or single-pole double-throw name shows that it has only one pole and two throws. Thus it can control one circuit at a time but the pole can conduct in both positions to two different terminals.

SPDT has 5 terminals with two terminals for the control signal, NC, NO and common terminal. It has two states where in either state one terminal conducts while the other doesn’t.

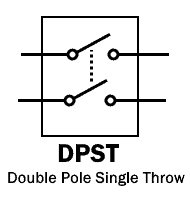

Double-Pole Single-Throw (DPST)

The DPST has two poles and single throw where its individual poles control separate circuits. However, the pole can conduct in only one position. It is similar to two separate SPST relays controlled using the same input signal.

It has 6 terminals with two for the input signal and two pairs of terminals for the control circuit.

Double-Pole Double-Throw (DPDT)

DPDT relay has two poles for controlling two separate circuits and two throws for conducting in both positions. It acts as two SPDTs using a common input signal.

A relay can have as many as 12 poles.

Related Posts:

- What is a Sensor? Different Types of Sensors with Applications

- What is a Transducer? Types of Transducers and Applications

Based on Applications

The EMR relay can be classified based on its applications.

Protection Relay

These are such relays that are used for the protection of circuits

Current and Voltage Relay

Such a type of relay is used to monitor the value of current and voltage in a circuit. It protects the circuit and trips the power if the voltage and current exceeds or falls from a certain value.

Differential Relay

Differential Relay is a type of EMR that compares two or more than two current signals. Therefore it is used for the protection of the circuit. They are highly sensitive with very fast switching speeds.

Distance Relay

It is a type of relay used for the protection of transmission lines. It is used to detect the fault in a line by measuring the impedance between the relay and fault location and comparing it with a preset value. If the impedance deviates it isolates the fault line. It is used for both phase fault and ground fault protection

Sequence Relay

The sequence relay has the ability to open or close its contacts in a predetermined sequence. It either works on a single pulse or a series of pulses with each pulse closing contacts one by one.

Target Annunciator Relay

It is another type of protection relay that has no automatic reset and must be reset manually. Therefore it is used to indicate the status of the connected device. It is also known as target relay, signal relay, or flag relay.

Ground Fault Relay

Ground fault relays are used to provide protection against ground faults. A ground fault is the abnormal current flow from the live wire to the ground or neutral wire. It may occur as a short circuit, or electrical shock to any living thing. The ground fault occurs due to damaged wire insulation or equipment.

Earth Fault Relay

Earth fault relays are used to protect against earth faults. An Earth fault is the flow of abnormal current from live wire to earth. The current may also power through a person to the earth and cause electrical shock. It quickly switches the circuit once it senses any earth leakage.

Power Factor Relay

As its name suggests, it is used to sense the power factor in a system and switch the inductive and capacitive power elements in the system to adjust the power factor. It is used to increase the efficiency of the electrical energy being used.

General Purpose Relay

Time Relay

Time relay as its name suggests is a type of relay that takes a certain time delay between the input signal and the change in its state. Other types of relays instantly trip or switch when the input signal is applied. It mainly acts as a time delay function.

Latching Relay

A latching relay is a type of relay that retains its last state. It does not change its state once the power is removed. Hence, it remains in either On or Off state. These kind of relays are used in refrigeration, HVAC, etc.

Rotary Relay

The rotary relay uses a rotating motion instead of the up/down movement of the arm. The rotary motion is provided by a small motor.

Flash Relay

The flash relay is used to generate a flickering light in case of tripping in order to draw attention rather than turning on a light.

Related Posts:

- Capacitor and Types Of Capacitors | Fixed, Variable, Polar and Non-Polar

- Inductor and Types of Inductors and Their Applications

Advantages and Disadvantages of EMR

Advantages

Here are some advantages of electromagnetic relays.

- EMR can be used for controlling both AC and DC circuits.

- It has a robust and simple design.

- Its switching speed can be adjusted.

- It has a fast operating speed

- It is quite cheaper than static relays.

- There is an audible confirmation of a clicking sound when it switches.

Disadvantages

Here are some disadvantages of electromagnetic relays.

- It generates an arc during the breaking of the circuit. The arcs damage the contacts decreasing their conductivity.

- The contacts may corrode or dust and pollution gather between them can reduce their efficiency over time.

- It requires periodic maintenance.

- The inertia of the contact arm limits the operating speed of the relay.

- It can conduct in both directions except for the polarized relay.

Applications of Electromagnetic (Electrotechnical) Relay

Electromagnetic relays are widely used for its robust design at low cost.

- It is used for the protection of an AC/DC circuit.

- It is used to isolate a low-voltage circuit from a high-voltage circuit.

- It is used as an automatic change-over switch.

- It is used to protect a device from overload and over-voltage.

- High-speed relays are used for the protection of sensitive equipment.

- It is used to drive a heavy load using a small signal such as in a microcontroller.

- They are also used for comparing different signals.

Related Posts:

- How to Test a Relay? Checking SSR and Coil Relays

- What is a Solenoid and Solenoid Magnetic Field

- Air Circuit Breaker (ACB) – Construction, Operation, Types and Uses

- MCB (Miniature Circuit Breaker) – Its Construction, Working, Types and Uses

- MCCB (Molded Case Circuit Breaker) – Construction, Types and Working

- What is an RCD (Residual Current Device)? – RCB and RCCB

- ELCB (Earth Leakage Circuit Breaker) – Construction, Types & Working

- How to Wire an RCBO? Residual Current Breaker with Overcurrent

- What is a Contactor ? Types, Working and Applications

- Relay Symbols – Electrical and Electronic Symbols

Related Premium Resources for Wiring Installation for Relays in Different Circuits

- How to Reverse Operation of Photo Eye for Motor using Relay?

- How to Wire ST01 Timer with Relay & Contactor for 120V/240V Motors?

- How to Wire AH3 OFF-Delay Timer and Relay with Boiler Fan?

- Automatic Phase Reverse Protection Using Contactors & Relay

- ON / OFF 3- Phase Motor Using 14-PIN Relay and DOL Starter

- How to Wire 14-PIN Relay for Holding or Latching Circuit?

- ON / OFF 3- Phase Motor Using 11-PIN Relay and DOL Starter

- How to Wire 11-PIN Relay for Interlocking and Holding Circuits?

- ON / OFF 3- Phase Motor Using 8-PIN Relay and DOL Starter

- How to Wire 8-PIN Relay for Holding or Latching Circuit?

- How to Control a Three-Phase Motor Using Solid-State Relay?

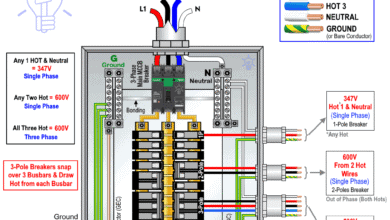

How to Wire 600/347V 3ΦY, 1-Phase & 3-Phase Load Center

How to Wire 600/347V 3ΦY, 1-Phase & 3-Phase Load Center What is the Main Difference Between FLA and FLC?

What is the Main Difference Between FLA and FLC? Difference Between Direct-On-Line (DOL) and Star Delta Starter

Difference Between Direct-On-Line (DOL) and Star Delta Starter Difference Between NEMA and IEC Motor Starters & Contactors

Difference Between NEMA and IEC Motor Starters & Contactors Part 14 – How to Size Star-Delta Starter for Motors?

Part 14 – How to Size Star-Delta Starter for Motors? Part 13 – How to Size DOL Starter for Three-Phase Motors?

Part 13 – How to Size DOL Starter for Three-Phase Motors?