Capacitor & Types Of Capacitors | Fixed, Variable, Polar & Non-Polar

Different Types Of Capacitors With Its Characteristics and Applications

A capacitor is one of the most used electronic components which is used in almost any kind of circuit. Its uses and characteristics rely upon the type of the capacitor. In this article, we will briefly discuss different types of capacitors.

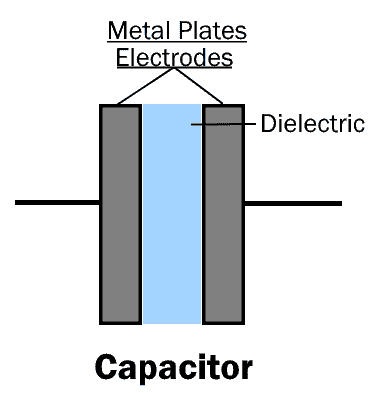

What is a Capacitor?

A capacitor is a two-terminal passive electronic component that stores charge in an electric field between its metal plates. it is made up of two metal plates (electrodes) separated by an insulator known as the dielectric.

Capacitance

The capacitance is the ability of a capacitor to store charge in its metal plates (Electrodes). Its unit is Farad F.

One Farad is the amount of capacitance when a charge of one-coulomb causes the potential difference of one volt across its terminals. The capacitance is always positive, it cannot be negative.

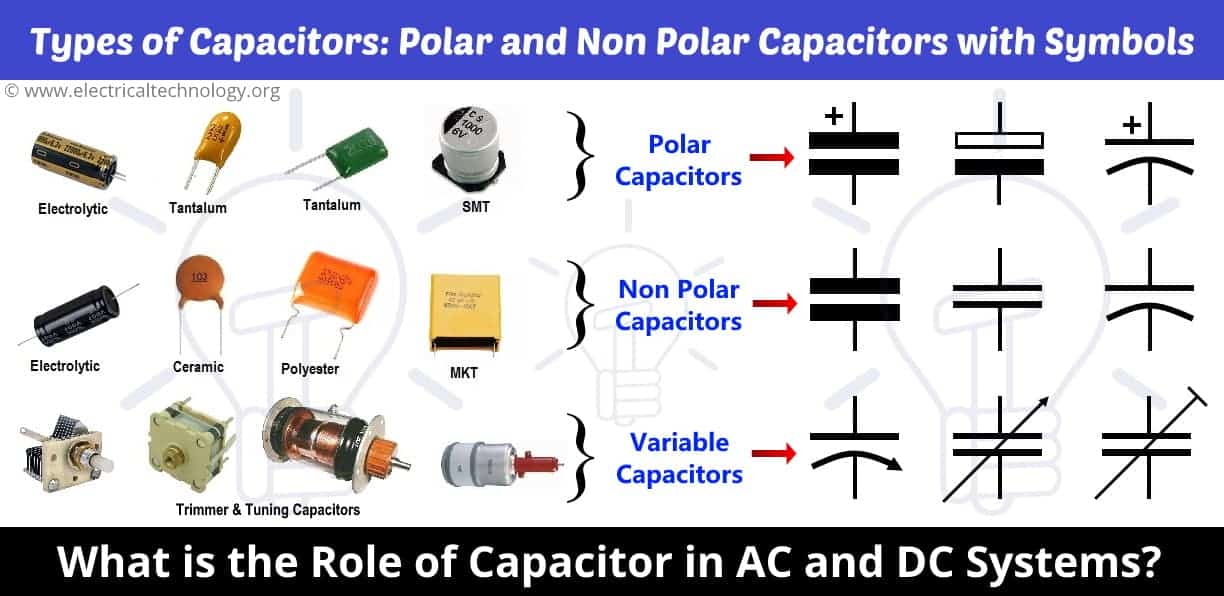

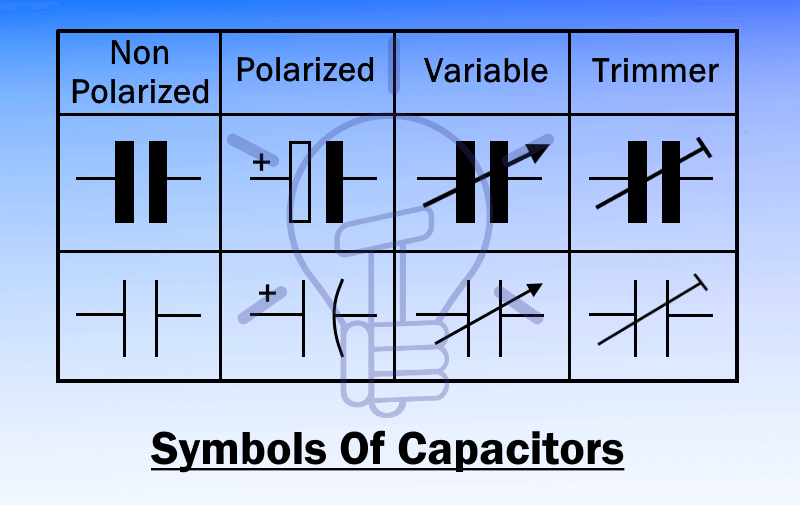

Symbols of Different Types Of Capacitors

Symbols of different Types of capacitors and its alternative symbols are given below.

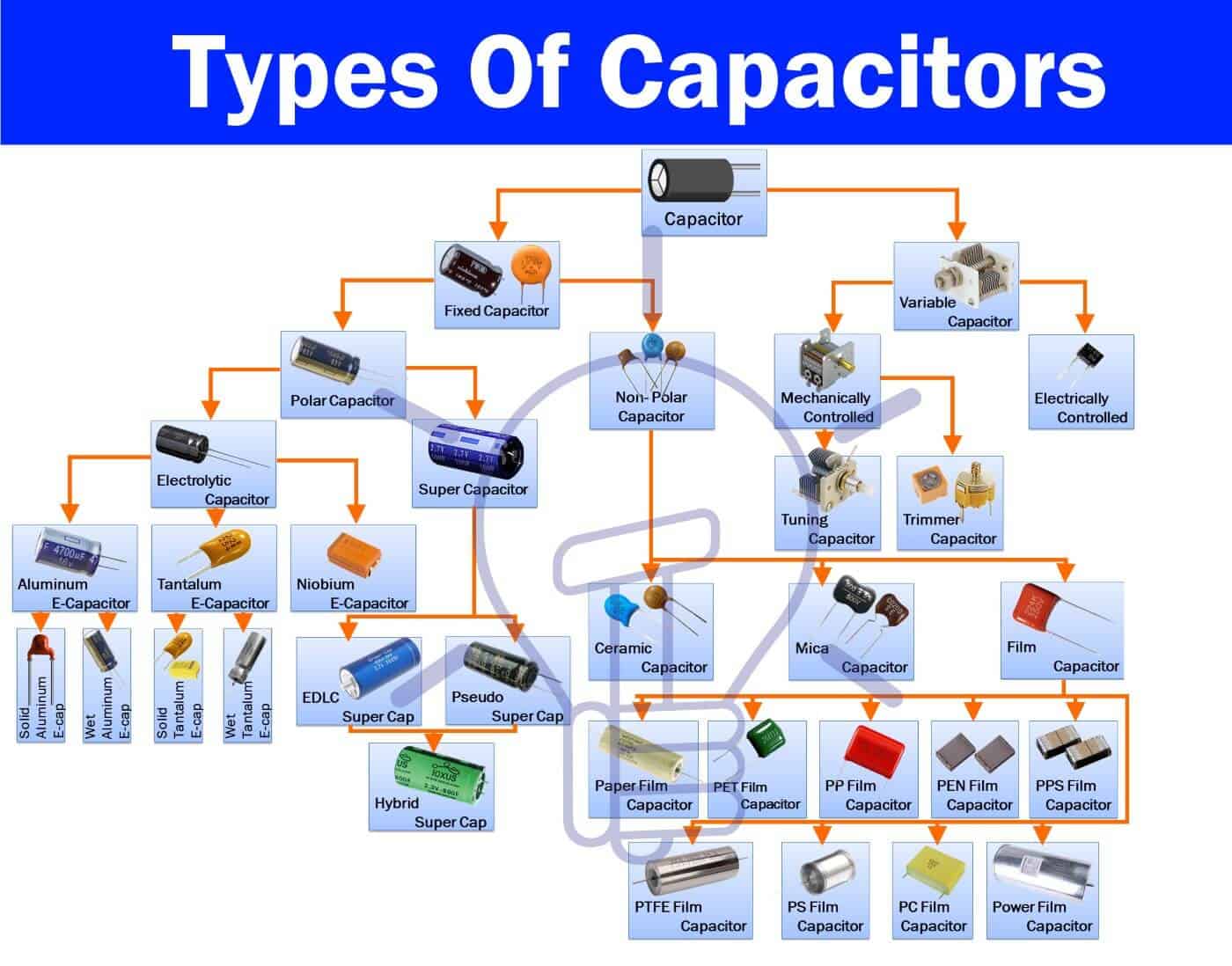

Types Of Capacitors

There are different types of Capacitors classified on the basis of their sizes, shapes and materials. Different types of capacitors are given below with details.

The two main types of capacitors are fixed capacitors and variable capacitors.

1) Fixed Capacitors:

As the name suggests, the fixed capacitor has a fixed capacitance value. It cannot be changed. Fixed capacitors are further divided into two types i.e.

1. 1. Polar Capacitors

1. 2. Non-polar Capacitors

1.1) Polar Capacitors:

Polar capacitors or polarized capacitors are such type of a capacitor whose terminals (electrodes) have polarity; positive and negative.

The positive terminal should be connected to positive of supply and negative to negative. Reversing the polarity will destroy the capacitor. These type of capacitors are only used in DC applications.

Polar capacitors are further classified into two types:

1.1.1. Electrolytic Capacitors

1.1.2. Supercapacitors

1.1.1) Electrolytic Capacitors:

An electrolytic capacitor is a type of polar capacitor that uses an electrolyte as one of its electrodes to maintain heavy charge storage. It is made up of two metal plates whose positive (anode) plate is covered with an insulating oxide layer through anodization. This insulating layer acts as the dielectric. The electrolyte is used as the second terminal cathode. The electrolytes can be solid, liquid or gas type material.

Such Types of capacitors have a high capacitance value ranging from 1 μF to 47000 μF. They are only used in DC circuits.

The electrolytic capacitors are classified into three families

1.1.1.1. Aluminum Electrolytic Capacitors

1.1.1.2. Tantalum Electrolytic Capacitors

1.1.1.3. Niobium Electrolytic Capacitors

1.1.1.1) Aluminum Electrolytic Capacitors

In the aluminum Electrolytic capacitor, the electrodes used are made of pure aluminum. However, the anode (positive) electrode is made by forming an insulating layer of aluminum oxide (Al2O3) through anodization. The electrolyte (solid or non-solid) is placed on the insulating surface of the anode. This electrolyte technically acts as the cathode. The second aluminum electrode is placed on top of electrolyte which acts as its electrical connection to the negative terminal of the capacitor.

Depending on its electrolyte, they are divided into two sub-types

1. Non-Solid or Wet Aluminum Electrolytic Capacitors

2. Solid Aluminum Electrolytic Capacitors (SAL’s)

1) Non-Solid Aluminum Electrolytic Capacitors

Non-solid aluminum electrolytic capacitors use liquid or gel electrolyte. They are made of two foils of aluminum with a paper in between which is impregnated with a liquid or gel-like electrolyte. The anode aluminum foil is oxidized to form (AL2O3) dielectric. The cathode foil serves the purpose of electrical contact for the electrolyte. Although, the cathode foil has a natural oxide layer formed by air which increases its capacitance.

The non-solid electrolytes normally used are

- Borax (ethylene glycol and boric acid) they have a max voltage rating of 600 v at a max temperature of 85° C to 105° C.

- Organic solvents such as dimethylformamide (DFM), dimethylacetamide (DMA) or gamma-butyrolactone. They have a relatively high-temperature rating (GBL) and leakage current.

- Water containing solvents with water up to 70% is famous for its low ESR (effective series resistance) and low cost.

The aluminum foils with paper in-between are wound together. They are impregnated in the electrolyte and then covered in a casing of aluminum.

Advantages

- Inexpensive

- Self-healing mechanism, it forms a new oxide form after applying voltage.

Disadvantages

- Due to evaporation, dry out over time reducing health.

- ESR increases with time.

- Only used in DC circuits.

- They are sensitive to mechanical stress.

Application

- Power factor correction.

- Flash capacitor for a camera.

- I/O filters in AC power supplies

- Coupling, decoupling.

2) Solid Aluminum Electrolytic Capacitors (SAL’s)

SAL has the same construction design as wet electrolytic capacitor except they use solid electrolytes like;

- Manganese dioxide (MnO2)

- Polymer electrolyte

- Hybrid electrolytes (solid polymer with liquid)

The electrolyte is sandwiched between two foils of aluminum after anodization of anode foil. They are then folded together for pearl style or wound for the radial style.

Advantages

- Due to its dry nature of electrolyte, there is no evaporation

- They have longer life-span

- They have low ESR

Disadvantages

- They are expensive

- No self-healing mechanism except hybrid polymer capacitor

Applications

Their application uses are similar to a non-solid electrolytic capacitor.

1.1.1.2) Tantalum Electrolytic Capacitors

Such type of electrolytic capacitor uses tantalum metal as an anode electrode. Tantalum pallet is oxidized to form an insulating layer of oxide that acts as the dielectric. This pallet is dipped into an electrolyte (solid or liquid). The electrolyte acts as a cathode. However, a layer of graphite and silver is coated on top of the electrolyte for cathode electrical connection.

Due to its thin oxide layer, tantalum capacitors have a high capacitance per volume as compared to other electrolytic capacitors. They are smaller in size.

Depending on the state of its electrolyte, they are classified into two subfamilies

1. Wet or Non-Solid Tantalum Electrolytic Capacitors

2. Solid Electrolytic Capacitors

1) Wet or Non-Solid Tantalum Electrolytic Capacitors

Wet tantalum capacitor uses liquid electrolyte such as sulphuric acid because the tantalum oxide layer is inert and stable. These capacitors operate on relatively high voltages up to 630 v with lowest leakage current compared to other electrolytic capacitors.

2) Solid Tantalum Electrolytic Capacitors

Solid tantalum capacitor uses solid electrolytes such as manganese dioxide (MnO2) or polymer.

MnO2 electrolytes have high stability whereas polymer electrolytes conductivity deteriorates with time.

Applications of Tantalum Capacitor

- Due to high capacitance per volume, it can replace aluminum electrolytic capacitor where temperature increases due to the dense packing of components.

- They are used in medical electronics for its high-quality results.

- Due to its low leakage current, they are used in sample and hold circuits.

- Most common application is filtering in computer power supplies due to its small size and reliability.

Advantages And Disadvantages

- They are available in small size and high capacitance.

- It is very stable and reliable, thus having longer life-span.

- It can operate on a wide range of temperature from -55° C to +125° C.

- They are expensive.

- They cannot tolerate reverse voltages.

1.1.1.3) Niobium Electrolytic Capacitors

In niobium electrolytic capacitor the anode is made of niobium metal (Niobium monoxide). It is oxidized through anodization to form an insulating layer of niobium pentoxide. This layer acts as the dielectric.

The electrolyte used in niobium electrolytic capacitor is solid i.e. either manganese dioxide or polymer electrolyte. This electrolyte covers the surface of the anode. The electrolyte acts as the cathode.

A graphite and silver layer is placed on top of the electrolyte for electrical contact of cathode terminal.

- Related post: Types of Solar Panel and Which one is the best PV Panel?

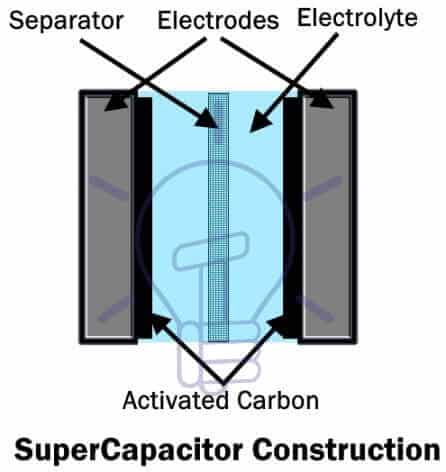

1.1.2) Supercapacitors:

A supercapacitor is also known as ultra-capacitor or Super cap. A supercapacitor is a type of polar capacitor that has very high capacitance but low voltage ratings.

These types of capacitors can deliver charge much faster than a battery and store charge more than an electrolytic capacitor per volume unit. That is why it is considered between a battery and an electrolytic capacitor.

Supercapacitor capacitance ranges from 100 F to 12000 F with low voltage ratings approximately 2.5 v to 2.7 v.

Supercapacitors construction is somewhat similar to electrolytic capacitors. They are made of metal foil (electrodes), each layered with activated carbon. These foils sandwich the separator in between. The separator is an ion-permeable membrane such as graphene (used in modern supercapacitor) which provides the insulation and exchange of ions of the electrolyte between the electrodes.

Subsequently, these foils are folded for rectangular or rolled for cylindrical shape and placed in an aluminum casing. It is then impregnated with an electrolyte, the electrolyte is rich in ions and conducts ions between electrodes. The casing is then sealed hermetically.

The supercapacitor store charge either using electrostatic double-layer capacitance (EDLC) or electrochemical pseudocapacitance or both known as hybrid capacitance. Thus, supercapacitors are classified into these types given above.

- Related Post: Difference Between Capacitor and Supercapacitor

1.1.2.1) Electrostatic Double-Layer Capacitors (EDLC’s)

It is a type of super cap that store charge electrostatically in double-layer. The electrodes are made of activated carbon. When the voltage is applied to its electrodes, two layers of charge are formed. One layer appears on the surface of electrodes, which causes another layer of opposite polarity ions in the electrolyte. These two layers are separated by a polarized monolayer of solvent molecules. It is known as the Helmholtz plane.

There is no charge transfer between electrodes and electrolyte which can cause a chemical change. So the charge is not stored in the chemical bond (electrochemically). Instead, there is an electrostatic force between the ions, so EDLC stores charge electrostatically.

- Related post: CAPACITOR BANKS and CHARACTERISTICS AND APPLICATIONS

1.1.2.2) Electrochemical PseudoCapacitors

This a type of supercapacitor which stores energy by transfer of charge between electrolyte and electrode, also known as faradaic-electron-charge-transfer. So they store charge electrochemically.

It is a very fast reversible redox reaction where reduction occurs at one electrode and oxidation at other during charging and vice versa during discharging.

The faradic-electron-charge-transfer occurs with double-layer capacitance. The ions flow through the inner Helmholtz layer to reach electrode. The charge transfer between the ion and electrode cause capacitance known as Pseudo capacitance. Its capacitance exceeds the double-layer capacitance by 100 times.

When the ions transfer the charge to an electrode they become fused (adsorbed) on the surface of the electrode. There is no chemical reaction between the ions and electron since only charge-transfer occurs.

The electrodes of Pseudo capacitor are made of transition metal-oxide (MnO2, IrO2) with doping of active carbon and a conductive polymer, which provides a porous and spongy structure. Its structural design resembles the EDLC.

1.1.2.3) Hybrid Super Capacitors

Hybrid supercapacitor uses the technology of both the EDLC and Pseudo capacitor by using two types of electrodes. One type of electrode is used for double-layer capacitance such as activated carbon (usually used as a cathode). The other electrode is used for pseudocapacitance.

The example of a hybrid supercapacitor is a Lithium-ion capacitor. Its anode terminal is made from graphite with doping of lithium ions during production which increases its output voltage compared to other supercapacitors. Its max voltage reaches up to 3.8 v.

The cathode forms electric double-layer capacitance on its side and the anode forms a Pseudocapacitance. A separator is used in between cathode and anode to prevent electrical contact between them.

Hybrid capacitors provide high energy density, high power density with high reliability.

Application of Super Capacitors

Modern technology has so many applications of supercapacitors. Some of them are given below

- Cordless electric screwdriver, which can be charged in a few minutes.

- LED flashlights in digital cameras.

- For stabilizing power supply in laptops and handheld devices etc.

- Uninterrupted power supply (UPS) where it replaces electrolytic capacitor banks.

Related Post: Capacitor Code: How to Find the value of Ceramic Capacitors?

1.2) Non-Polar Capacitors:

Non-polar or non-polarized capacitors are such types of capacitors whose terminals have no fixed polarity. They can be used either way in a circuit. Due to its non-polarized terminals, they are used in DC circuits as well as AC circuits.

They are cheaper than Polar capacitor but they have low capacitance and high range of voltage ratings from a few volts to thousands of volts.

Non-polar capacitor are classified into three types

1.2.1. Ceramic Capacitor

1.2.2. Mica Capacitor

1.2.3. Film Capacitor

1.2.1) Ceramic Capacitors:

As the name suggests the ceramic capacitor is a type of non-polar capacitor in which the dielectric used is a ceramic material.

It is made of two layers of metal (usually nickel and copper) with ceramic (Para electric or Ferroelectric) as the dielectric. These alternating layers are stacked together to provide high capacitance value.

The minimum thickness of the ceramic dielectric layer is about 0.5 μm. The voltage rating of the capacitor depends on its dielectric strength. Furthermore, the terminals are attached to electrodes and the capacitor is covered in ceramic protective layer against moisture.

Related Post: What is the difference between a battery and a capacitor?

Ceramic capacitors are available in different shapes and styles.

- Ceramic disc shape: most commonly used type of ceramic capacitor having one layer of ceramic disc sandwiched between electrodes with through-hole terminals.

- MLCC: multi-layer ceramic chip is rectangular shaped with multiple alternating layers of metal and ceramic material with surface mounting terminals

The parameters of the ceramic capacitor depend on the different compositions of the ceramic dielectric. Due to which, they are classified into four classes.

1.2.1.1) Class 1

Class 1 ceramic capacitor uses Para electric material such as Titanium dioxide (TiO2). They are most accurate with most stable voltage and temperature. They have the lowest losses. Its capacitance value does not depend on the applied voltage. They do not age.

Class 1 ceramic capacitor has a very low volumetric efficiency (low capacitance over large space) thus they have low capacitance value. This is because of the fact that Para electric material has low permeability.

They are used in the applications where capacitance stability and low losses are the utmost requirements such as resonant circuits.

- Related post: What is the Role of Capacitor in AC and DC Circuit?

1.2.1.2) Class 2

Class 2 ceramic capacitors use a Ferroelectric material with other additives as the dielectric. It has high permeability, which provides a relatively higher volumetric efficiency than a class1 ceramic capacitor. They are very smaller than class1.

They have low accuracy and stability with a non-linear change of capacitance with temperature. Also, its capacitance value varies with applied voltage and they age over time.

These types of capacitors are used for coupling, decoupling and by-pass applications where capacitance stability is not required.

1.2.1.3) Class 3 and 4

Class 3 also known as barrier-layer ceramic capacitors uses the dielectric with higher permeability than class 2. That is the reason they have better volumetric efficiency but with worst electrical parameters.

Its capacitance changes non-linearly with temperature with a very high margin. Also, it depends on the applied voltage. It has the worst stability and accuracy with very high losses. They age over time.

In modern electronic technology, they are considered obsolete, instead, class 2 ceramic capacitors are preferred. Class 4 has even worse parameters than class 3 and they are also obsolete as of today.

- Related Post: How to Calculate the Suitable Capacitor Size in Farads and#038; kVAR for Power factor Improvement?

1.2.2) Mica Capacitors:

Mica capacitor as its name suggests is a non-polar capacitor that uses mica (chemically inert and stable material) as the dielectric.

There are two type of mica capacitor

1.2.2.1. Clamped Mica Capacitor

1.2.2.2. Silver Mica Capacitor

1.2.2.1) Clamped Mica Capacitors

These types of capacitors were used in the early 20th century. They were constructed from thin sheets of mica and metal (usually copper) foil. These sheets and foils are stacked together and clamped. They were then encapsulated in insulating material.

The tolerance and stability of clamped mica capacitor are worse than other capacitors because the surface of mica is not flat and smooth.

Nowadays, There are obsolete and are replaced by silver mica capacitor discussed below.

1.2.2.2) Silver Mica capacitors:

Unlike clamped mica capacitor where sheets of mica are clamped with metal foils, the silver mica capacitor is made of sheets of mica with metal (silver electrode) being coated on its both sides. Multiple layers are added together to increase its capacitance. It is then dipped in an insulator Epoxy for protection against humidity and air etc.

They are very stable and have low losses. They have a low tolerance of about +/- 1%. Its capacitance depends very little on the applied voltage. The encapsulation protects the electrodes from corrosion. Thus, they maintain a longer lifespan.

They are costly and have a larger volume as compared to ceramic capacitors. It can operate on heavy voltage ranging from 100 v to 10 Kv with capacitance ranging from 47 pF to 3000 pF.

They are still used in modern electronic circuits because of its high voltage and power handling capabilities such as RF broadcast transmitter, amplifiers, high voltage inverters, and resonance circuits etc.

1.2.3) Film Capacitors:

Film capacitor, also known as Polymer film capacitor or plastic film capacitor is a type of non-polar capacitor which uses a film of usually plastic and sometimes paper as a dielectric.

Its construction has two types or formats of configuration

- Metalized Capacitor

- Film/Foil Capacitor

Related Post: High Inrush Current in Capacitor Switching and Ways to Prevent It.

1.2.3.1) Metalized Capacitors

Metalized capacitors are those types of capacitors that use a metalized dielectric film, which is made by depositing a metal layer over the dielectric film. The metal used can be Aluminum or Zinc.

Such configuration provides self-healing property and the film can be wound together to achieve capacitance up to 100uF

1.2.3.2) Film/Foil Capacitors

Such types of capacitors are constructed by sandwiching a dielectric film with metal foils. The metal is usually Aluminum which acts as the electrodes.

Such type of configuration enables the capacitor to handle high surge currents.

The film capacitors are divided into different types of capacitors based on the type of dielectric film.

1.2.3.3) Paper Capacitors

It is the first film capacitor where an oil-impregnated paper was used as a dielectric between Aluminum foils.

The main drawback of paper film/foil capacitor was that it soaks moisture, which degrades its performance over time. They were fairly bulky.

Nowadays, Metallized paper films are used as a dielectric with a self-healing property. The paper is combined with polypropylene film to increase its voltage rating and improve its performance.

Power capacitor that uses paper as a dielectric, is filled with oil to fill the air gaps increasing its breakdown voltage.

- Related Post: How to Convert Capacitor Farads into kVAR and#038; Vice Versa (For Power factor improvement)?

1.2.3.4) Polyester (PET) Film or Mylar Capacitors

Polyester film capacitor, also known by its trademark name Mylar capacitor uses a dielectric made of polyethylene terephthalate (PET), which is a thermoplastic polar polymer. They are constructed in both metalized film and Film/Foil structure as well.

Its ability to resist moisture makes the capacitor to be used without coating. Its high permeability and dielectric strength offer high volumetric efficiency. However, its capacitance temperature coefficient is a little higher than other film capacitors. It can operate in temperature up to 125° C. This also allows it to be used as an SMD capacitor. They operate on a maximum voltage of about 60 Kv. They have a tolerance of 5% to 10%.

1.2.3.5) Poly Propylene (PP) Film Capacitors

Polypropylene is a non-polar organic polymer material that is used as a dielectric in this capacitor.

They are manufactured in both configurations i.e. metalized film and film/foil.

They are even more resistant to moisture than polyester film capacitor, thus they don’t need any protective coating. Their capacitance is less dependent on temperature and frequency as compared to polyester but its operating frequency is lower with a max limit of 100 KHz. Its max operating temperature is 105° C. They have high operating voltage with a maximum voltage rating of 400 Kv.

They are used in high-power induction heating and low-power application such as sample and hold and VCO etc. they are also used as AC motor run capacitor and power factor correction capacitor.

- Related Post: Capacitors MCQs with Explanatory Answers

1.2.3.6) Polyethylene Naphthalate (PEN) Film Capacitors

The dielectric material used in such type of film capacitors is Polyethylene Naphthalate (PEN) which belongs to the polyester family. These capacitors are only available in metalized dielectric structure.

The main advantage of PEN capacitors is its high-temperature stability of about 175° C. Due to high-temperature stability; they are manufactured in SMD packaging.

It has low volumetric efficiency because the PEN dielectric has lower permeability and strength compared to PET. However, its capacitance dependence on its temperature and frequency is similar to PET capacitors, which is why they are used in applications where temperature dependencies are not required.

There are used for coupling, decoupling and filtering purposes.

1.2.3.7) Polyphenylene Sulfide (PPS) Film Capacitors

These film capacitors are available in only metalized film form. Their capacitance depends very little on the temperature and frequency compared to other film capacitors.

It offers a very stable response for the temperature below 100° C. Its dielectric can withstand temperature up to 270° C. Therefore, they are also made in SMD packaging. However, they are costly compared to other film capacitors.

They are used in applications where high operating temperatures exist.

1.2.3.8) Polytetrafluoroethylene (PTFE) Film Capacitors

Also known by its trademark name Teflon, uses a synthetic polymer Polytetrafluoroethylene (PTFE) as the dielectric. They are manufactured in both metalized and Film/foil types.

They are fairly bulky and expensive. The temperature dependence for its capacitance is a little higher than the Polypropylene (PP) film capacitor. But they are very resistant to a temperature of about 200° C with very low losses.

They are used in high-quality applications for aerospace and military equipment.

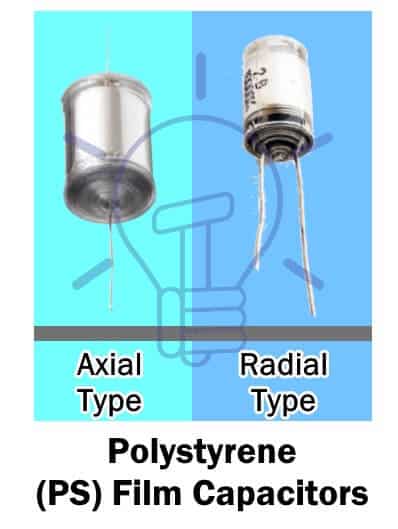

1.2.3.9) Polystyrene (PS) Film Capacitors

The main advantage of these capacitors is that they offer almost zero change in its capacitance when operating in its temperature range. But they have a very low-temperature rating with the maximum limit of 85° C.

These film capacitors are cheap capacitors with very low losses and high stability. They are manufactured in tubular shape and are now replaced by polyester film capacitor.

They are used for general-purpose applications having low temperature and frequency.

1.2.3.10) Polycarbonate (PC) Film Capacitors

These film capacitors use polycarbonate dielectric which is manufactured in both metalized and film/foil structure as well.

They offer very high stability and very low loss. It is almost independent of the temperature in the range of -55° to +125° C. The Polycarbonate film provides high tolerance which increases its reliability.

They are used in the applications where low-loss and temperature stability is required such as filtering and timing circuits in a harsh environment.

1.2.3.11) Power Film Capacitors

They have the similar construction as film capacitor. The layers are wound together to attain a larger size and capable of handling high power. They are used in high power AC and DC applications.

2) Variable Capacitors:

Such types of capacitors whose capacitance can be changed either mechanically or electrically is known as the variable capacitors. They don’t have fixed capacitance value instead they provide a range of values. They are used in tuning LC circuits for a radio receiver, impedance matching in antennas.

These variable capacitors are divided into two main types based on its operating mechanism

2.1. Mechanically Controlled

2.2. Electrically Controlled

Related post: Insulating And Dielectric Materials – Types, Properties and Applications

2.1) Mechanically Controlled Variable Capacitors

These variable capacitors capacitance value can be changed mechanically through a knob or a screwdriver. They are made of semi-circular metal plates with a dielectric in between them.

One set of plates which is movable is known as rotor and the other set of plates which is stationary is known as the stator. The rotor rotates around a shaft that increases or decrease the distance between the plates which changes the capacitance of the capacitor.

Mechanical controlled types of capacitors are further divided into two sub-types.

2.1.1. Tuning Capacitors

2.1.2. Trimmer Capacitors

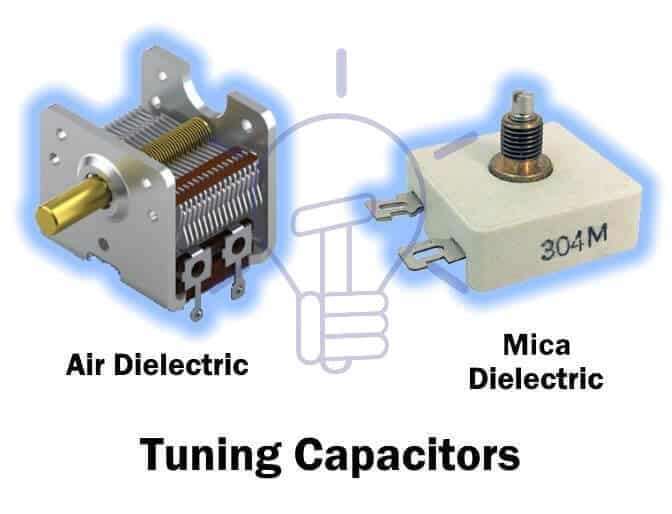

2.1.1) Tuning Capacitors

This type of variable capacitor is used for tuning and is commonly used in LC circuits for radio tuning. Its capacitance can be varied by rotating a knob which rotates the rotor across the stator with a dielectric between them. The dielectric used is either air or mica.

They are a more robust type of variable capacitor. It is used in such circuits where the capacitance needs to be changed more than once in order to achieve the desired output.

2.1.2) Trimmer Capacitors

This type of variable capacitor’s capacitance is varied by using a screwdriver. They are not very tolerant to continuous changing in capacitance. They can only withstand a few adjustments.

It has the same construction design as a tuning capacitor. The dielectric used in the trimmer capacitor is either air or ceramic.

They are used in such circuits where the capacitance does not need to be changed more than a few times. They are used in calibration circuits of equipment. Their small size allows it to be used on PCB (Printed Circuit Board).

Related Post: All About Electrical Protection Systems, Devices And Units

2.2) Electrically Controlled Variable Capacitors

Such type of variable capacitor is made of P-N junction semiconductor device whose junction capacitance is controlled using the reverse voltage.

Varactor diode or more commonly known as Vericap is a special type of diode that uses the reverse bias voltage to vary its junction capacitance.

They are used in PLL (Phase locked loop) as VCO (voltage controlled oscillator) and as frequency synthesizers

Applications of Capacitors

There are some of the general application for all types of capacitors.

- Smoothing power supply’s output.

- Power factor correction

- Frequency filters, high pass, lowpass filters.

- Coupling and Decoupling of signals.

- Motor Starter.

- Snubber (Surge absorber and Noise filter)

- Oscillators

Miscellaneous and Obsolete Types of Capacitors

There are other miscellaneous types of capacitors which are given below.

Integrated Capacitor: They are manufacture inside an IC by metallization and isolation of substrate.

Vacuum Capacitor: They are used for High Power RF transmission.

Special Capacitor: They are designed on a multilayer PCB (Printed Circuit Board).

Obsolete Capacitors: These types of capacitors are considered obsolete as of today and replaced by far advanced technology.

- Layden jars capacitor

- Air-gap Capacitor

Related Posts:

- What is the Role of Capacitor in a Ceiling Fan?

- What Happens if We Connect a Polar Capacitor the Wrong Way?

- How to Replace a Ceiling Fan Capacitor – 3 Ways

- Why Does A Capacitor Block DC But Pass AC?

- Types of Inductors and Their Applications

Very useful information. How can I copy it to teach?