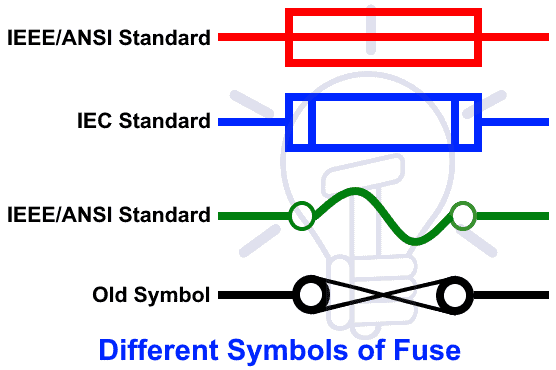

Fuse and Types of Fuses – Construction, Operation & Applications

Different Types of Fuses – Constriction, Working & Characteristics

What is a Fuse?

A fuse is an electrical / electronic or mechanical safety device designed to protect circuits from overcurrent and overload conditions. Invented by Thomas Alva Edison in 1890, fuses are used widely to safeguard electrical systems during electrical faults.

While various types of fuses exist, their fundamental function remains the same: to interrupt the flow of current when it exceeds a predetermined limit. in today’s explanatory article for protective devices, we will discuss different types of fuses, their construction, operating principles, and applications within various electrical and electronic systems.

- Related Post: Main Difference between Fuse and Circuit Breaker

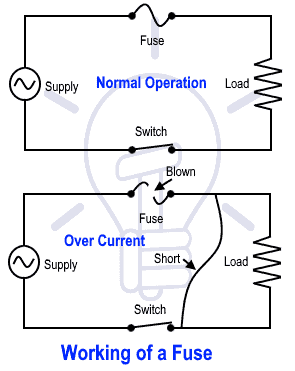

Construction & Working of a Fuse

A general fuse consists of a low resistance metallic wire enclosed in a non combustible material. It is used to connect and install in series with a circuit and device which needs to be protected from short circuit and over current, otherwise, electrical appliance may be damaged in case of absence of the fuse and circuit breaker as they are unable to handle the excessive current according to their rating limits

The working principle of a fuse is based on the “Heating effect of current” i.e. Whenever a short circuit, over current or mismatched load connection occurs, then the thin wire inside the fuse melts because of the heat generated by the heavy current flowing through it. Therefore, it disconnects the power supply from the connected system. In normal operation of the circuit, fuse wire is just a very low resistance component and does not affect the normal operation of the system connected to the power supply.

Characteristics of a Fuse

Different types of fuses can be categories on the following characteristics.

- Current Rating & Current Carrying Capacity of Fuse

- Voltage Rating of Fuse

- Breaking Capacity of a Fuse

- I2t Value of Fuse

- Response Characteristic

- Rated voltage of Fuse

- Packaging Size

Below is the brief explanation of the above categories.

Fuse Current Carrying Capacity

Current carrying capacity is the amount of current which a fuse can easily conduct without interrupting the circuit.

Breaking capacity:

The value of maximum current that can safely be interrupted by the Fuse is called Breaking Capacity and should be higher than the prospective short circuit current.

- Related Post: How to Read MCB Nameplate Data Rating Printed on it?

Rated Voltage of Fuse

Expect the current capacity of current, there is the maximum voltage rating a fuse can handle safely. Each fuse has maximum allowed voltage rating, for example, if a fuse is designed for 32 volts it cannot be used with 220 volts, different amounts of isolation is required in different fuses working on different voltage levels. Bases of voltage rating, a fuse can be HV (High Voltage) LV (Low Voltage), and Miniature Fuses.

I2t Value of Fuse

The I2t terms related to fuse normally used in short circuit condition. It is the amount of energy which carries the fuse element when the electrical fault is cleared by the fuse element.

Response Characteristic of a Fuse

The speed at which the fuse blows, depends on the amount of current flowing through its wire. The higher the current flowing through the wire, faster will be the response time.

Response characteristic shows the response time for an overcurrent event. Fuses which respond rapidly to the over current situation is called ultra fast fuses or Fast fuses. They are used in Many semiconductor devices because semiconductor devices are damaged by over current very rapidly.

There is another fuse which Is called a slow burn fuse, switch fuses do not respond rapidly to the over current event, but blow after several seconds of over current occurrence. Such fuses found their application in motor control electronics systems because motors take a lot more current at starting than running.

Packaging Size

As we have mentioned above, AC and DC fuses have a little bit different packaging type, in the same way different applications require different packages to be used accurately in the circuit.

other factors and parameters are marking, temperature derating, voltage drop and speed etc.

Classification of Fuses

Fuses can be classified as “One Time Only Fuse”, “Resettable Fuse”, “Current limiting and non – current limiting fuses” based on the usage for different applications.

One time use fuses contain a metallic wire, which burns out, when an over current, over load or mismatched load connect event occurs, the user has to manually replace these fuses, switch fuses are cheap and widely used in almost all the electronics and electrical systems.

On the other hand, the Resettable fuse automatically reset after the operation when fault occurs at the system.

In the Current limiting fuse, they produce high resistance for a very short period while the non – current limiting fuse produces an arc in case of high current flow to interrupts and limit the current in related and connected circuits.

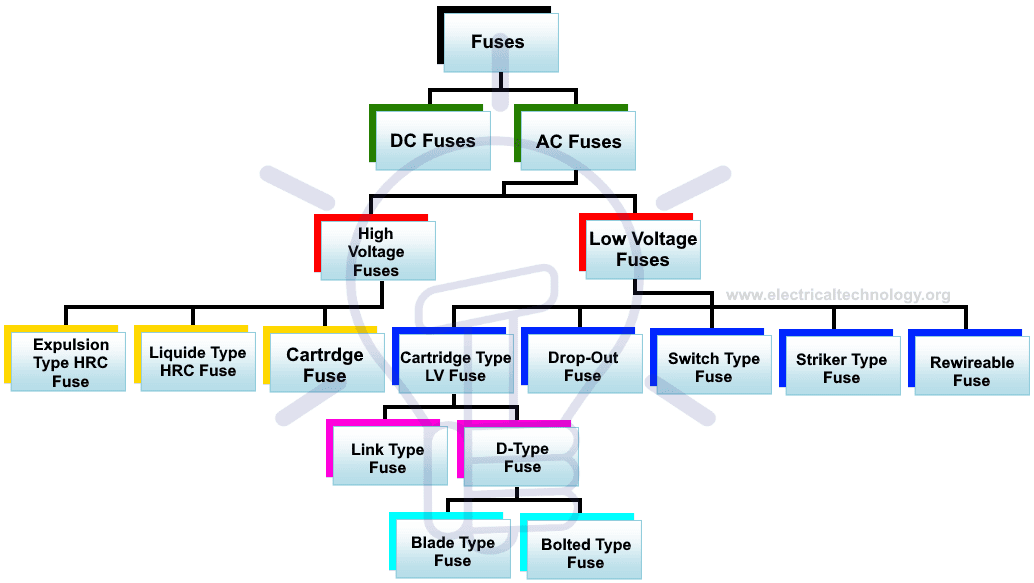

Types of Fuses

There are different types of fuses available in the market and they can be categories on the basis of Different aspects.

Good to know: Fuses are used in AC as well as DC circuits.

Click image to enlarge

Fuses can be divided into two main categories according to the type of input supply voltage.

- AC fuses

- DC fuses

There is a little difference between AC and DC fuses used in the AC and DC Systems which has been discussed below.

DC Fuses

In a DC system, when the metallic wire melts because of the heat generated by the over current, then Arc is produced and it is very difficult to extinguish this arc because of DC constant value. So in order to minimize the fuse arcing, DC fuse are little bigger than an AC fuse which increases the distance between the electrodes to reduce the arc in the Fuse.

AC Fuses

On the other hand, i.e. in the AC system, voltage with 60Hz or 50Hz frequency changes its amplitude from zero to 60 times every second, so arc can be extinct easily as compared to DC. Therefore, AC fuses are a little bit small in sizes as compared to DC fuses.

Fuses can also be categorized based on one time or multiple operations.

- Related Post: Fuse, Circuit Breaker and Protection Symbols

Cartridge Fuses

Cartridge fuses are used to protect electrical appliances such as motors, air-conditions, refrigerator, pumps etc, where high voltage rating and currents are required. They are available up to 600A and 600V AC and widely used in industries, commercial as well as home distribution panels.

There are two types of Cartridge fuses. 1. General purpose fuse with no time delay and 2. Heavy-duty cartridge fuses with time delay. Both are available in 250V AC to 600V AC and its rating can be found on the end cap or knife blade.

Cartridge Fuses are enclosed in a base and can be divided further in Link type cartridge fuses and D Type Cartridge Fuses.

D – Type Cartridge Fuse

D-Types fuse contains an adapter ring, base, cap and cartridge. Fuse base is connected to the fuse cap where the cartridge is inside the fuse cap. The circuit is completed when the tip of the cartridge makes contacts through the fuse link conductor.

HRC (High Rupturing Capacity) Fuse or Link Type Cartridge Fuse

We have previously discussed in detail High Rupturing Capacity (HRC) fuses, also known as cartridge or link type fuses, including their construction, operation, and applications. This discussion covered various types of HRC fuses such as DIN type, NH Type, Blade Type, Liquid Type HRC Fuse, and Expulsion Type HV Fuse, along with their advantages and disadvantages.

High Voltage Fuses

High Voltage (HV) fuses are used in power systems to protect the power transformer, distribution transformers and instrument transformer etc. where circuit breakers may be inadequate. HV fuses are designed for high-voltage applications, typically exceeding 1500V and ranging up to 13kV.

The element of High Voltage fuse is generally made of copper, silver or tin. The fuse link chamber may filled with boric acid in case of expulsion type HV (High Voltage) Fuses

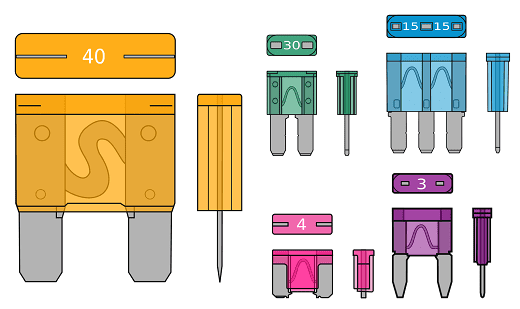

Automotive, Blade Type & Bolted Type Fuses

These types of fuses (also known as spade or plug-in fuses) come in plastic body and two metal caps to fit in the socket. Mostly, they are used in automobiles for wiring and short circuit protection. Fuse Limiters, Glass Tube (also known as Bosch Fuse) are widely used in automotive industries. The rating of automobile fuses are low as 12V to 42V.

In bolted types of fuses, the base of the fuse contacted directly to the base of the fuse, same like HRC Fuses, to read more about Blade Type and Bolted types of fuses related to HRC fuses, check the post. Types of HRC Fuses.

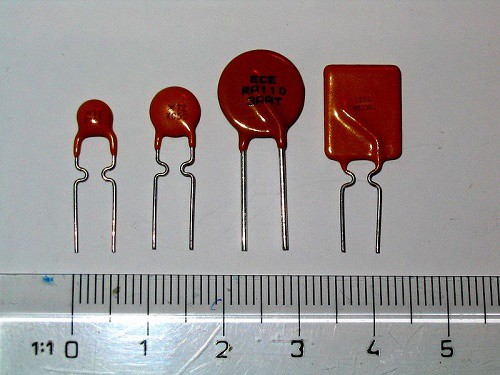

SMD Fuses (Surface Mount Fuse), Chip , Radial, and Lead Fuses

SMD Fuses (Surface Mount Device and the name derived from SMT = Surface Mount Technology) are chip types of fuses (also known as electronic fuse) are used in DC power applications like Hard Drive, DVD players, Camera, cell phones etc. where space playing an important role because SMD fuses are very tinny in size and hard to replace as well.

Below are some additional types of SMD Fuses and Leaded fuses.

- Slow – Blow Chip Fuses

- Fast Acting Chip Fuses

- Very Fast Acting Chip Fuses

- Pulse Tolerant Chip Fuses

- High Current Rated Chip Fuses

- Telecom Fuses

- Through-hole styles fuses

- Radial Fuse

- Lead Fuse

- Axial Fuse

Rewireable Fuses

The most famous kit-kat fuse (also known as rewireable fuse) mostly used in industries and home electrical wiring for small current applications in Low Voltage (LV) systems.

Rewireable fuse contains 2 basic parts. The inner fuse element as fuse carrier made of tinned copper, Aluminum, Lead etc. and the base made of porcelain having the IN and OUT terminals which is used to be in series with the circuit to protect.

The main advantage of a rewireable fuse is that It can be rewired easily in case it is blown due to short circuit or over current which melts the fuse elements. Simple, put another wire of fuse elements with the same rating as before.

Thermal Fuses

As mentioned above, thermal fuse is a one time used only fuse. They are temperature sensitive fuse and the fuse element is made of temperature sensitive alloy. They are known as Thermal Cutouts (TCO) or Thermal Links.

In a thermal fuse, the fuse element holds a mechanical spring contact which is normally closed. When high currents due to over current and short circuit flow through the elements of the fuse, the fuse elements melts down which lead to release the spring mechanism and prevent the arc and fire and protect the connected circuit.

Related Article: All About Electrical Protection Systems, Devices And Units

Resettable Fuses

Resettable fuse is a device, which can be used multiple times without replacing it. They open the circuit, when an over current event occurs and after some specific time they connect the circuit again. Polymeric positive temperature coefficient device (PPTC, commonly known as a resettable fuse, poly-switch or poly-fuse) is a passive electronic component used to protect against short current faults in electronic circuits.

Application of resettable fuses is overcome where manually replacing fuses is difficult or almost impossible, e.g. fuse in the nuclear system or in an aerospace system.

How to Choose the Right Fuse Size?

While selecting the proper fuse and its rated size for electrical appliances is based on different factors and environments. But the following basic formula shows how to choose the right size of fuse?

Selecting the proper fuse and its rated size for electrical appliances depends on various factors and environmental conditions. However, the following basic formula can guide you in selecting the right fuse size for typical applications.

Fuse Rating = ( Power ÷ Voltage ) x 1.25

To determine the proper fuse size for an electrical appliance, consider the following example: For a two-pin socket or outlet with a total load of 600W connected to a 120V supply, you can calculate the required fuse rating.

For example:

Fuse Rating (in Amps) = (Load in Watts / Supply Voltage) x 1.25

(600W ÷ 240V ) x 1.25 = 5A

This formula can be applied to 230V or 240V circuits as well. In this case of 120V circuit, the minimum fuse size should be equal to 5 Amps to or higher than the calculated value.

In the above case, the minimum size of the fuse should not be less than 5A for safe and reliable operation of the circuit.

Related Posts:

- How to Find the Proper Size of Circuit Breaker? Breaker Calculator & Examples

- How to Find The Suitable Size of Cable & Wire for Electrical Wiring Installation?

Uses and Applications of Fuses

Different types of Electrical and Electronic Fuses can be used in all types of electrical and electronic systems and applications including:

- Motors & Transformers

- Air-conditions

- Home distribution boards

- General electrical appliances and devices

- Laptops

- Cell phones

- Game systems

- Printers

- Digital cameras

- DVD players

- Portable Electronics

- LCD monitors

- Scanners

- Battery packs

- Hard disk drives

- Power convertors

Related Articles and Resources:

- Types of Circuit Breakers

- Types of Switches

- Types of Light Switches

- Types of Relays, Mechanical and SSR Construction & Operation

- Types of Contactors – Working and Applications

- Types of Electrical Wires and Cables

- Types of Resistors and their Applications

- Types of Inductors and Their Applications

- Types of Capacitors and Their Applications

- Types of Electrical Drawing and Diagrams

- Types of Fire Alarm Systems and Wiring Diagrams

- Types of Solar Panels

- Types of Insulators used in Power Transmission and Overhead Lines

- Types of Faults and Motor Protection Devices

- What is an RCD (Residual Current Device)? – RCB and RCCB

- What is an RCBO (Residual Current Breaker with Overcurrent)?

- ELCB (Earth Leakage Circuit Breaker) – Construction, Types & Working

nice (Y)

Thank You Very Much ….. Verrrrrry Goooooood

you are doing good job!

thank you soo much ……….. as you help me any time.

WHAT IS THE DIFFERENCE BETWEEN ULTRA FAST FUSES AND HRC FUSE, ARE THEY SAME or they are different. please clarify

nice information is uploaded here …..thank you for guiding us…..

nice information

It is very useful for me to rapidly and brifely briefly understand any topic on electrical field

To begin with it is a condensed informative article which I feel as very useful. However, I got a question. What will be the impact of selecting an AC fuse to keep it in the rotor circuit of a slip ring induction motor? Since the arcing time continues up to the current zero (which matches with slip frequency)I feel that the fuse body will be subjected to higher pressure due to thermal energy and has the probability of pressure rupture.

thank you so much for showing the different types of fuses.