Difference Between Solid-State Relay and Electromechanical Relay

Difference Between Electromechanical and Solid-State Relay – SSR vs EMR

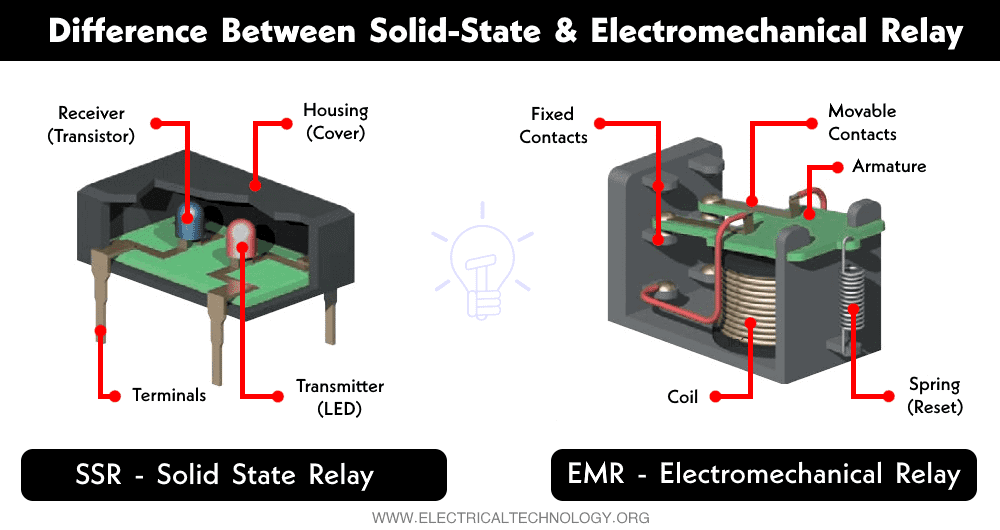

Solid State Relay (SSR) and Electromechanical Relay (EMR) are both different types of electrical relays used in electronic circuits. Both of them are used for switching high-voltage circuits using a low-voltage signal. The major difference between these two is that the SSR does not have any moving parts and EMR does. Other than that there are other several differences between them.

Before going into the list of differences between Solid State Relay and Electromechanical Relay, we are going to discuss their basics first.

What is Relay?

A relay is an electrically operated switch that uses a low-power signal to switch on or off a high-power signal. It opens or closes its contacts based on the supplied voltage. We can say it is an automatic switch that does not require manual switching instead electrical signal is used to switch it.

There are several types of electrical relays used mainly for the automatic switching of the high-power circuit. Two main types of relays are Electromechanical and solid-state relay.

Related Posts: Different Types of Relays, Their Construction, Operation and Applications

Electromechanical Relay

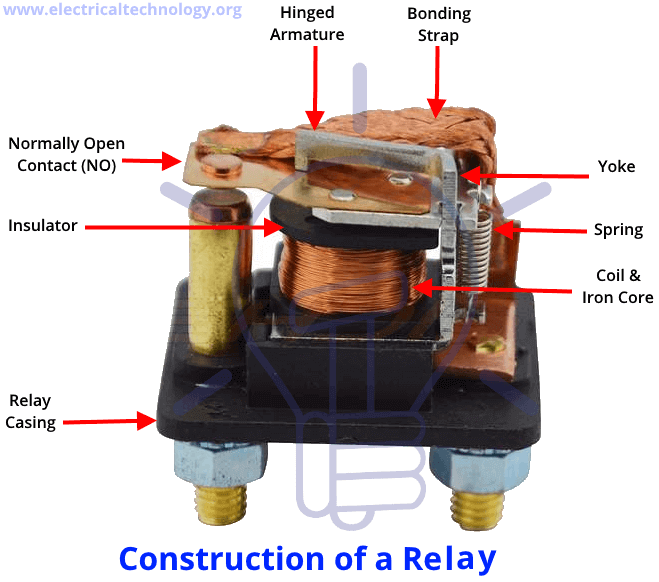

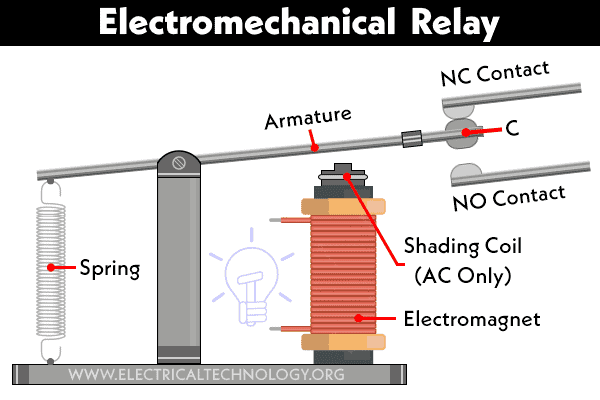

The Electromechanical relay (also known as Electromagnetic Relay – EMR) is the most generic type of electrical relay and is most common due to its low price and high power ratings. As the name implies, such relays have a physically moving contact that controls the flow of electric current in a high-power circuit. The contact is controlled using a movable arm that is attracted or repelled using an electromagnetic coil. A small voltage signal is used to energize the coil to produce the necessary magnetic field.

EMR consists of the following parts; electromagnetic coil, armature and contacts. The contact is placed on an armature that switches places due to the magnetic force applied by energizing and de-energizing the coil. The electromagnetic coil is placed below the armature which pulls the armature down to close the contacts.

EMR has two types of contacts i.e. normally closed NC and normally open NO contacts. The normally closed contacts are those contacts that remain closed until the electromagnetic coil is energized and opens with energizing the coil. The other set of contacts is the normally open contacts that remain open and close once the coil is energized. There are multiple sets of contacts available in the EMR relay that can support both AC and DC as well. The contact losses are very minimal as compared to semiconductor losses.

EMR uses the electromagnetic properties of a coil to provide isolation between a low and high-power circuit. Since it has moving contacts, it generates an arc whenever the contacts close or open. The arc produces noise in the system apart from the mechanical clicking sound. However, the clicking sound also provides an audible confirmation when the relay is triggered.

- Related Posts: Electromechanical Relay or Electromagnetic Relay (EMR)

Solid State Relay

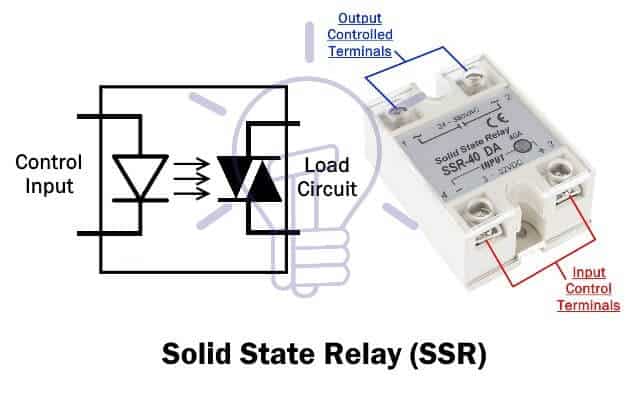

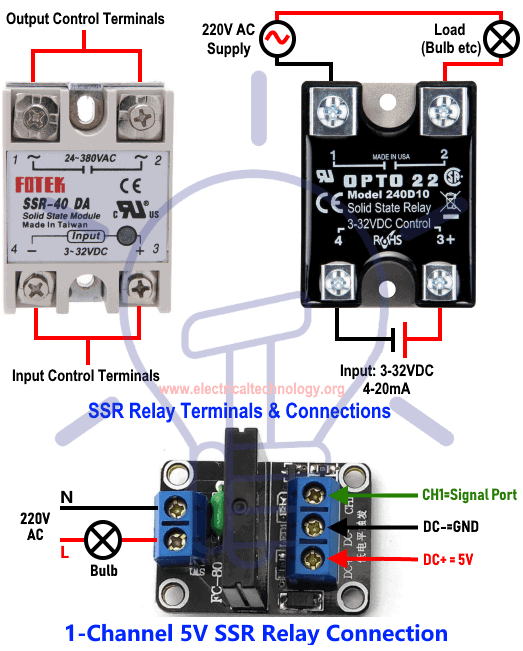

SSR or solid-state relays are a type of relay that uses semiconductor material instead of the electromagnetic coil. It is the advanced more complex version of the relay that optically couples the two circuits together. It uses a very low-power electrical signal to generate a light ray that triggers the switching of the output circuit.

The SSR has the following parts; an optocoupler, output driver circuit and semiconductor switching devices such as a thyristor, TRIAC, or MOSFET. The optocoupler provides physical isolation between the low and high-power circuit and provide optical coupling between them.

Since there are no moving parts, the semiconductor switching does not produce any noise even when switching large currents and require a very small signal to operate. Additionally, the switching time is 100 times faster than the EMR. There are no voltage surges. As there are no physical contacts, they are immune to corrosion or extreme weather conditions. Mechanical shocks or vibrations do not affect its performance. Overall, they are more compact and robust having a longer lifespan almost 100 times that of EMR relays.

The SSR being the advanced version of a relay has its cons too. Apart from its high cost, it generates a large amount of heat. Therefore they are equipped with large heat sinks for the dissipation of heat. Due to the semiconductor PN junction, there is a voltage drop between its contacts and the output voltage must exceed the junction threshold limit. Therefore they are not suitable for small signals. It also has a leakage current in the open state.

Another disadvantage of SSR is that it has only a single set of contacts per relay. There are no multipole, multi-throw contacts in SSR. Furthermore, they can either allow AC or DC and they are not compatible with both. They are sensitive to voltage transients.

- Related Posts: Solid State Relay (SSR) – Types, Construction and Operation

Differences Between Solid State Relay and Electromechanical Relay

The following table shows the comparison between electromechanical relay (EMR) and solid state relay (SSR).

| Electromechanical Relay | Solid State Relay |

| An electromechanical relay is a type of relay that uses physical contacts to switch circuits. | Solid state relay is a type of relay that uses a semiconductor PN junction to switch circuits. |

| It uses an electromagnetic coil to generate magnetic force to pull the armature down and switch the contacts. | It has an optocoupler that generates a light signal. It triggers the photosensitive SCR or TRIAC and allows the flow of current. |

| It has physical contact or moving parts. | It has semiconductor switches, therefore it does not have moving parts. |

| It consumes relatively large power to switch the load circuit. | It requires very low power and provides an energy-efficient solution. |

| It has usually multipole and multi-throw contacts | It has only a single set of contacts. |

| Its contacts can switch both AC and DC as well. | It can either switch AC or DC. |

| It has a low switching speed with a very low initial cost. | It has a high initial cost with a very high switching speed even compatible with digital logic circuits. |

| Vibrations and mechanical shocks affect its performance. | Since there are no moving parts, vibration or mechanical shock does not affect it. |

| Arcs are generated during the switching of physical contacts. | There are no arcs generated as there are no mechanical contacts. |

| It generates switching noise as well as electromagnetic interference in the system. | There is no arcing to generate EMI in the power system. |

| Its contacts get eroded and wear over time. Thus it has a lower lifespan. | There are no contacts to wear thus it has a longer lifespan. |

| The arcs create hazards in the environment having volatile and combustible materials. | They are safe to operate in a volatile combustible environment. |

| It has poor performance for frequent switching of large currents. | It has better performance for rapid switching of large currents. |

| It has no leakage current in the open state. | It has leakage current through its PN junction in the open state. |

| It has a negligible contact voltage drop. | It has a large ON state voltage drop at its PN junction. |

| It does not require heat sinks. | Voltage drops generate a large amount of heat thus they require large heat sinks. |

Related Posts:

Main Differences Between EMR and SSR

Input

The input signal of an EMR is used to energize a coil that produces a magnetic field to pull the armature having sets of contacts. It takes a certain amount of voltage and current to hold the armature in place and it is relatively large. The input of an EMR is defined by coil voltage and coil current, holding current and drop out current.

The input signal to SSR is used to control the semiconductor switch using an optocoupler as there’s no coil. Therefore the input is only defined by the control voltage and control current. The control voltage and control current is relatively very small as compared to EMR.

Moving parts

The main difference between EMR and SSR is the moving contact. SSR does not have any moving parts instead it uses a light signal to vary the resistance of its semiconductor junction. Whereas EMR uses a spring, armature mechanism controlled by an electromagnetic coil.

The absence of moving parts makes the SSR superior to the EMR as they are immune to mechanical shock and vibrations and its orientation.

Response Time

The time taken between the input signal and the switching of the contacts i.e. turn on and turn off is called response time.

The EMR having physical contacts being pulled by an electromagnetic force takes more time as compared to the electronically controlled switching of the SSR. Therefore, the SSR has relatively fast switching times almost a hundred times faster than EMR. A faster response time is often required in industries for better performance.

Voltage and Current Rating

The voltage and current ratings depend on the design and manufacturer of the relay. However, SSR can handle large currents without worrying about the sparks that could create hazards in a combustible environment.

Voltage Drop

Voltage drop refers to the voltage that appears across the contacts of the relay in the closed state. Ideally, the contacts have zero resistance in the closed position. However practically, there is a small resistance due to the worn or corroded contacts in EMR and the semiconductor PN junction in SSR.

Relatively, the semiconductor PN junction offers greater contact resistance. Therefore, SSR has a higher voltage drop of around 1.4 volts. It is insignificant as compared to the switching voltage. However, it generates heat which requires large heat sinks.

Heat Generation

As stated above, the voltage drop at the contacts causes power loss in the form of heat. Therefore SSR generates relatively more heat as compared to EMR of the same ratings. It is also due to the fact that a large number of semiconductors are closely packed in a small device. Thus it requires large heatsinks to result dissipate the heat.

Voltage Isolation

The EMR uses the air gap between the contacts as insulation that has infinite resistance. On the other hand, SSR has PN junctions that offer very high resistance in switched off state but still it is measurable (Finite). Therefore, the EMR provides higher voltage insulation.

Leakage Current

Leakage current refers to the current that flows through the contact in off state. Since the EMR provides infinite resistance in off state, the leakage current does not exist. However, SSR has certain off-state resistance that causes a leakage current. This leakage current depends on the voltage across its terminals as well as the design.

Related Posts:

- Electronic Relay Switch Circuit – NPN, PNP, N and P Channel Relay Switches

- Difference Between Relay and Circuit Breaker

Operation Modes

Right off the bat, SSR has various operation modes while the EMR can operate in only one mode. The EMR has a very simple operation that depends only on the input control signal and independent of the load circuit. thus it operates asynchronously.

On the other hand, the SSR internal circuit can be designed to achieve different modes of operation such as Synchronous, Asynchronous, voltage zero mode, pulse mode and phase angle modes.

Electromagnetic Interference EMI

The coil in the EMR generates electromagnetic interference in the power system. These electromagnetic radiations can damage the electronic components in an electric circuit. It requires an external protection circuit to reduce its effects.

The SSR has a very low EMI which can be further reduced with the use of the zero-crossing function. It also eliminates the effects of external EMI.

Mechanical Shock and Vibrations

The SSR is immune to mechanical shock and vibrations as there are no physical contacts. Whereas the EMR is susceptible to vibration as well as its orientation.

Life Span and Stability

The life span of the relay depends on the life of the mechanical contacts. The contacts generate arc due to frequent switching that gradually corrodes its surface and reduces its life span. Since there are no physical contacts in the SSR, they have a prolonged life span.

Power Consumption

The EMR requires large input power signal to operate as compared to SSR. The power consumption also depends on the size of the armature. The SSR has very low power consumption features.

Efficiency

The SSR is more efficient than EMR as it has low power consumption and overall cost.

Cost

The initial cost of SSR is higher than that of the EMR. Overall the SSR cost less than EMR in the long run due to the high maintenance cost as well as the high power consumption and the low lifespan of EMR.

Related Posts:

- Difference Between 50 Hz and 60 Hz Frequency System

- Difference Between Multiplexer (MUX) & Demultiplexer (DEMUX)

- Difference Between Encoder and Decoder?

- Difference Between Phototransistor and Photoresistor (LDR)

- Difference Between Voltage Source and Current Source

- Difference Between HP & BHP? Horsepower vs Brake Horsepower

- Difference Between LED and LDR

- Difference between Photodiode and Photoresistor (LDR)

- Difference between LED and Photodiode

- Difference Between Photodiode and Phototransistor

- Difference Between Thermistor and Thermocouple

- Difference Between Sensor and Actuator

- Difference between Sensor and Transducer

- Difference Between Current Transformer & Potential Transformer

- Difference Between D-MOSFET and E-MOSFET

- Difference Between NPN and PNP Transistor

- Difference Between Diode and Transistor

- Difference Between DIAC and TRIAC

- Difference between Electron Current and Conventional Current

- Difference Between Single Phase & Three Phase Induction Motor

- Difference Between Single Phase and Three Phase Power Supply

- Difference Between GFCI and AFCI

- Difference Between Current and Voltage

- Difference between AC and DC (Current & Voltage)

- Difference Between Voltage and EMF?

- Difference Between Overcurrent, Overload and Overvoltage

- Difference between Lightning Arrester and Surge Arrester

- Difference between AC Drives and DC Drives

- Difference Between Microprocessor and Microcontroller

- Difference Between EMF and MMF

- Main Difference between Contactor and Starter

- Main Difference between Fuse and Circuit Breaker

- Difference Between MCB, MCCB, ELCB & RCD

- Difference Between Neutral, Ground and Earth?

- Difference between Star and Delta Connections – Comparison Of Y/Δ

- Difference Between Electrical and Electronic Engineering?

- Difference Between Power Transformers and Distribution Transformers?