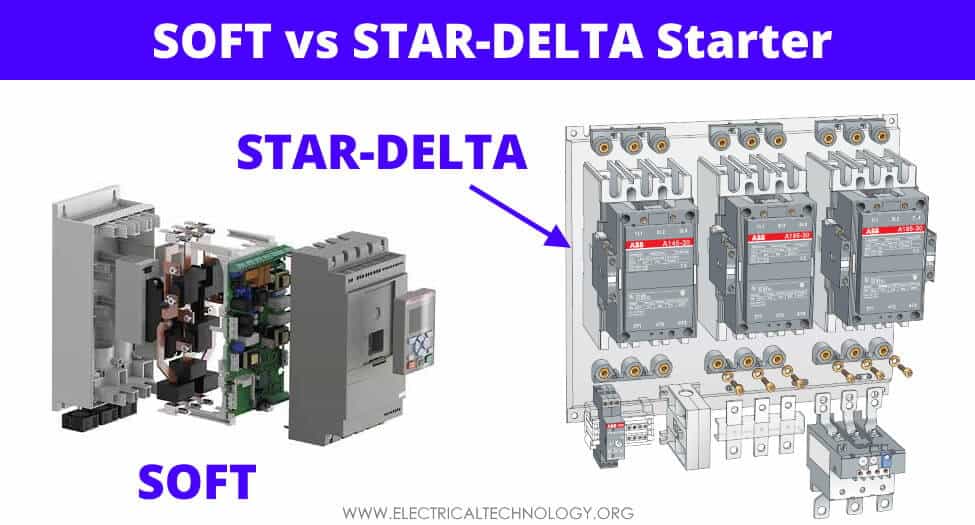

Difference Between Soft Starter and Star Delta Starter

What is the Difference between Soft Starter & Star Delta Starter (Y-Δ)?

Soft Starter and the star delta starter are two different types of motor starters. A motor starter is a device that safely starts and stops a motor & protects the machine from the huge starting inrush current. They also offer low voltage protection as well as overcurrent protection. That’s the reason we need to use motor starters.

Both of these starters use the technique of voltage reduction to reduce the starting current. Other than that, they are quite different based on every other feature. Before going into the list of differences between soft starter & star delta starter, let’s study them first a little bit.

Related Posts:

Star Delta Starter (Y-Δ)

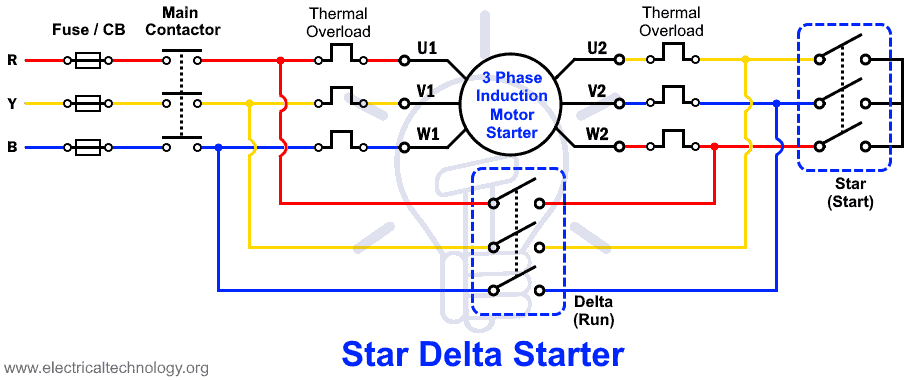

The Star-Delta starter aka Y-Δ or Wye-Delta Starter is the most common type of motor starter used in industries to safely start & stop large induction motors. It reduces the large starting current by reducing the voltage supplied to the motor.

As we know, the star connection reduces the phase voltage by 1/√3 which subsequently reduces the starting current. The motor’s winding at startup is connected in star configuration to reduce the inrush current. Once the motor picks up the speed, the windings are switched to delta configuration to resume the full voltage supply.

Its design is very simple & it is very cheap. But the downside is that there are more wire connections.

There is no flexibility in its starting characteristics such as the star connection allows 1/√3 of starting current which generates fixed starting torque that is 1/3 of the rated value.

Due to limited starting features, It can only be used for starting a motor in unloaded condition. & it has a fixed starting time which cannot be adjusted.

There is a mechanical jerk when the star connection is switched into the delta connection to resume the full voltage. You may know more about the differences between star and delta connection and STAR to Delta and vice versa transformation in the previous posts.

Related Posts:

- DC Machine – Construction, Working, Types and Applications

- Speed Control of DC Motor – Voltage, Rheostatic & Flux Control Methods

Soft Starter

The soft starter is a motor starter made of semiconductors such as thyristors or SCR (silicon controlled rectifiers) to regulate the voltage supply to the motor. The voltage at startup is reduced to reduce the inrush current that can damage the motor windings. The voltage is gradually increased until it reaches rated speed.

In a three-phase soft starter, three pairs of thyristors are connected in back-to-back formations to control the voltage supply to the motor. The firing angle of the thyristor controls its conduction period. Therefore, varying the firing angle vary the voltage supply to the motor.

During the motor startup, the inrush current is reduced by reducing the voltage to minimum, which is gradually increased by varying the firing angle. This gradual voltage increase allows a smooth acceleration. Once the motor reaches its rated speed, the starter is bypassed using a contactor & the full voltage supply from the mains is resumed. During stopping, the voltage supply is reduced to decelerate the motor smoothly. Once the motor slows down completely, the voltage supply is stopped.

Soft starter allows us to control & gradually increase the voltage from 0% to 100%. Therefore, it offers flexibility in the starting characteristics. Whereas star-delta starter has a fixed voltage for starting that limits its flexibility.

The Low voltage at startup protects the motor from damage due to a high inrush current that could burn its windings. In star-delta, the star connection reduces the voltage as well as the starting current by factor 1/√3 which is still larger than the soft starter.

The soft starter smoothly increases the speed of the motor at startup while in star-delta starter, the swapping between star to delta connection suddenly increases the current & torque which causes a mechanical jerk in the machine.

The mechanical jerks which are absent in soft starter increases the mechanical life & reduces the maintenance schedule of the motor. while in star-delta, it is somewhat of a concern to inspect the motor once in a while.

The smooth startup & controlled acceleration of the soft starter makes it a perfect candidate to be used in conveyor, belt & pulley system and cranes.

Since it reduces the input voltage that corresponds to the input current which is directly proportional to the starting torque of the induction motor, it significantly reduces the starting torque. But it is dynamic & it can be controlled which is why soft starters are used for low to medium starting torque applications. While the star-delta starter due to its fixed low starting current only offers low starting torque which cannot be adjusted.

It offers a fully adjustable acceleration & deceleration of the motor. Varying the firing angle slowly or quickly can control the acceleration during startup & deceleration during stopping of the motor. While the star delta starter has a fixed acceleration due to a fixed starting current.

It can handle both loaded & unloaded conditions during the startup of a motor. It also allows us to adjust the starting time of the motor.

Since it offers a gradual & smooth increase in speed & it is more reliable, it can be used for heavy motor such as in cranes, conveyor belts, etc.

Related Posts:

- Single-Phase Induction Motor – Construction, Working, Types & Applications

- Three-Phase Induction Motor – Construction, Working, Types & Applications

Differences between Star Delta Starter & Soft Starter

The following table shows the main differences between Star-delta starter and SOFT Motor starters.

| Star Delta Starter | Soft Starter |

| A motor starter that reduces the starting current by changing the winding’s configuration between star & delta. | A solid-state motor starter that reduces the starting current by varying the conduction period of the thyristors or SCR. |

| It has two voltage states i.e. low voltage which is 1/√3 of line voltage(star connection) & full line voltage (delta connection). | It has infinite voltage states electronically controlled from 0% to 100% of line voltage. |

| It has limited & fixed starting characteristics. | Its starting characteristics are flexible & can be adjusted based on application. |

| The starting current abruptly increases when switched between star & delta connection. | It offers a smooth startup with a gradual increase in current. |

| It does not offer a soft stop feature. | It also offers a soft stop feature. |

| It offers low & fixed starting torque. | It offers low to medium & adjustable starting torque. |

| The starting time is fixed. | The starting time can be controlled. |

| It is used for starting the motor in unloaded conditions. | It can be used for starting the motor in both loaded & unloaded conditions. |

| It has a simple design but too many wire connections. | It has a complex design but with few wire connections. |

| Its installation is very complex. | It is very easy to install. |

| Switching between star & delta causes an open circuit & momentarily power loss which causes current transients. | The power supply is continuous & there is no power loss. Hence no such transients. |

| It is cheaper & less efficient than a soft starter. | It is expensive but more efficient than a star-delta starter. |

| It is used for running large induction motors in unloaded conditions. | It is used for running conveyor belts, cranes, the motor with belts & pulley. |

Why Choose Soft Starter?

Since the costs of solid-state devices have lowered significantly in the past decade, the soft starter although it is slightly expensive than a star-delta starter, is used for large electric motors in applications that require frequent start & stop. Not to mention, it also offers many other useful features such as adjustable starting torque, starting time, soft stop feature & no power loss. It can handle variable load conditions. The lack of any moving parts increases the lifetime of the starter & the smooth motor operation prolongs its life & requires less maintenance.

- Related Post: Main Difference between Contactor and Starter

Why Choose Star-Delta Starter?

The star-delta starter is mostly used due to its cheaper cost. & since it has very low starting torque, it is used for handling very small loads. It should be used for machines that rarely start & stops. Although, its very low starting voltage makes it the best candidate for lifting very small loads better than the soft starter.

Related Posts:

- What is Soft Starter? Its Working, Diagram and Applications

- Star Delta Starter – (Y-Δ) Starter Power, Control and Wiring Connection

- STAR-DELTA Starter Motor Starting Method Without Timer

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- Motor Protection – Types of Faults and Protection Devices

- Types of Electric Motors – Classification of AC, DC & Special Motors

- What is a Contactor ? Types, Working and Applications

- Why We Need to Install a Starter with a Motor?