SF6 Circuit Breaker – Types, Construction, Working and Applications

SF6 Circuit Breaker (Sulfur Hexafluoride Circuit Breaker) – Construction & Working Principle

Circuit breakers are used for protection against fault current in electrical systems. They abruptly break the circuit and safely quench the arc. The circuit-breaking part is easy as it is just the separation of contact but the arc that generates afterward which prevents the circuit from breaking and causes damage needs to be quenched as fast as possible. That’s where we use SF6 circuit breaker in HV circuit for arc quenching.

The arc strength depends on many variables such as voltage, the gap between the contacts, temperature, pressure, etc. The arc can be quenched using various techniques and mediums. The SF6 circuit breaker is one of the many types of circuit breakers that uses the SF6 gas as the arc quenching medium to safely break the high voltage circuit.

What is an SF6 Circuit Breaker?

Sulphur Hexafluoride or SF6 circuit breaker is a type of circuit breaker that uses pressurized SF6 (sulfur hexafluoride) gas to extinguish the arc. It is a dielectric gas having superior insulating and arc quenching properties far better than air or oil. It is used for arc quenching in high voltage circuit breakers up to 800 kV in power stations, electrical grids etc.

SF6 gas has very high electronegativity. It has a strong tendency to absorb free electrons. When an arc is struck between the contacts, it absorbs the free electrons from it. It converts into negative ions which are heavier than electrons. Due to its heavyweight, its mobility is reduced. Therefore, the mobility of the charges in SF6 gas has low mobility which enhances the dielectric strength of the medium since the movement of charges is responsible for current flow.

Related Post: Oil Circuit Breaker (OCB) – Types, Construction, Working and Applications

Properties of SF6 Gas

The fact that makes the SF6 better arc quenching medium is due to its physical and chemical properties that are given below.

Physical Properties

Physical properties of SF6 gas

- It is non-flammable gas.

- It is colorless and odorless gas.

- It has excellent thermal conductivity.

- It has high density and heavier than air.

- It liquefies at low temperature which is pressure-dependent.

Chemical Properties

Chemical properties of SF6 gas

- SF6 gas is stable and inert.

- It is non-toxic in its pure form but its products are.

- It has high electronegativity meaning it has a strong affinity for free electrons.

- It recombines very easily after arc quenching for re-utilization.

- They are non-corrosive.

Electrical Properties

- It has superior dielectric strength which is directly proportional to the pressure.

- Its arc quenching capabilities is almost 100 times better than air.

- The frequency of the voltage does not affect its dielectric strength.

Related Post: Air Circuit Breaker (ACB) – Construction, Operation, Types and Uses

Construction of SF6 Circuit Breaker

The SF6 circuit breakers consist of two main parts

- Interrupter Unit

- Gas System

Interrupter Unit

The interrupter unit consists of two types of current-carrying contacts i.e. the fixed and movable contact. The fixed contacts as its name suggest do not move while the movable contact moves back and forth using an arm actuated by a mechanism.

There is a vent for the inlet and outlet of the pressurized SF6 gas to cool off the arc as well as extinguish it.

Gas System

The SF6 is a very expensive gas and the emission of its product gases is hazardous for the environment. Therefore, a closed gas system is used, where the used SF6 is recombined for reuse. Its pressure is also maintained as its dielectric strength greatly depends upon it.

Working Principle of SF6 Circuit Breaker

The SF6 gas is compressed and stored inside a tank. During the fault conditions, the contacts are separated and an arc is struck between them. The highly pressurized SF6 gas is also released at the same moment.

The arc which is the movement of charges contains free electrons. The SF6 being highly electronegative, absorbs the free electrons forming negative ions. These ions are heavier and have low mobility as compared to free electrons.

SF6 + e– = SF6–

SF6 + e– = SF5– + F

Due to the heavy mass of the formed negative ions, the movement of the charges reduces between the contacts. This increases the dielectric strength of the medium that quenches the arc at zero current. The blast of SF6 gas also reduces the temperature of the arc which also reduces its strength. The pressure of the gas is also directly proportional to the dielectric strength of the SF6 gas.

Types of SF6 Circuit Breaker

The following types of SF6 circuit breakers are explained in detail below.

- Non-Puffer Type SF6 Circuit Breaker

- Single Pressure Puffer Type SF6 Circuit Breaker

- Double Pressure Puffer Type SF6 Circuit Breaker

Non-Puffer Type

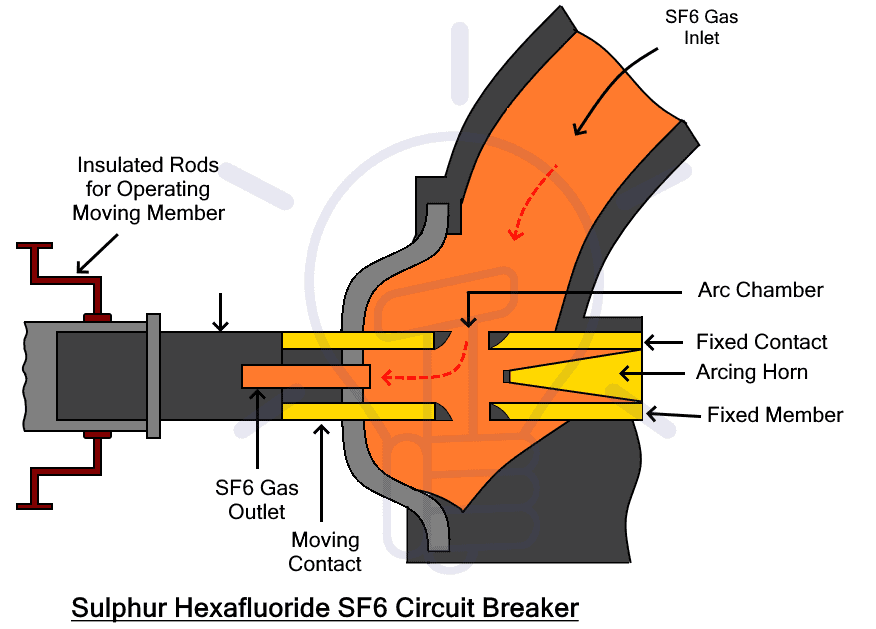

Such type of SF6 circuit breaker is the first invented circuit breaker that does not include the puffer cylinder. This circuit breaker works on the same principle as air blast CB. Its construction and working mechanism is given below.

Construction

It consists of a gas chamber and interrupter unit. The SF6 gas is compressed and stored inside a gas chamber. The gas chamber is connected to the interrupter unit through a valve. The valve is linked with the movement of the contacts. as soon as the contacts separate, the valve is opened to release a blast of SF6.

The arc quenching occurs inside the interrupter unit or arc chamber. It has two types of contacts i.e. moving contact and fixed contact. The contacts are hollow cylinders. The fixed contacts include arc horns that are used for protection against arcs. The tip of the arc horns is covered with copper-tungsten to have extra resistance. The moving contact includes a vent. The vent is used as an outlet for the SF6 gas from the arc chamber.

The moving contact moves back and forth to make or break the circuit. It is attached with an actuator through an insulating rod that actuates the whole moving contact assembly by moving back and forth. The actuator is synchronized with the gas chamber’s valve which releases the gas at the same movement the contact separates.

Working

Under normal conditions, the contacts remain closed and the compressed SF6 remains in the gas chamber. When a fault occurs, the moving contact begins to move and separate from the fixed contact. The medium surrounding the contacts gets ionized and an arc is produced between the contacts.

At the same time, the gas chamber’s valve will open and release the pressurized SF6 into the arc chamber. The SF6 quenches the arc as explained before. The blast of SF6 also cools off the arc.

The SF6 flows out through the outlet where the gas is recombined. The gas is recompressed and stored in the gas chamber for reuse. The gas system is fully enclosed and it is constantly monitored for any leakage.

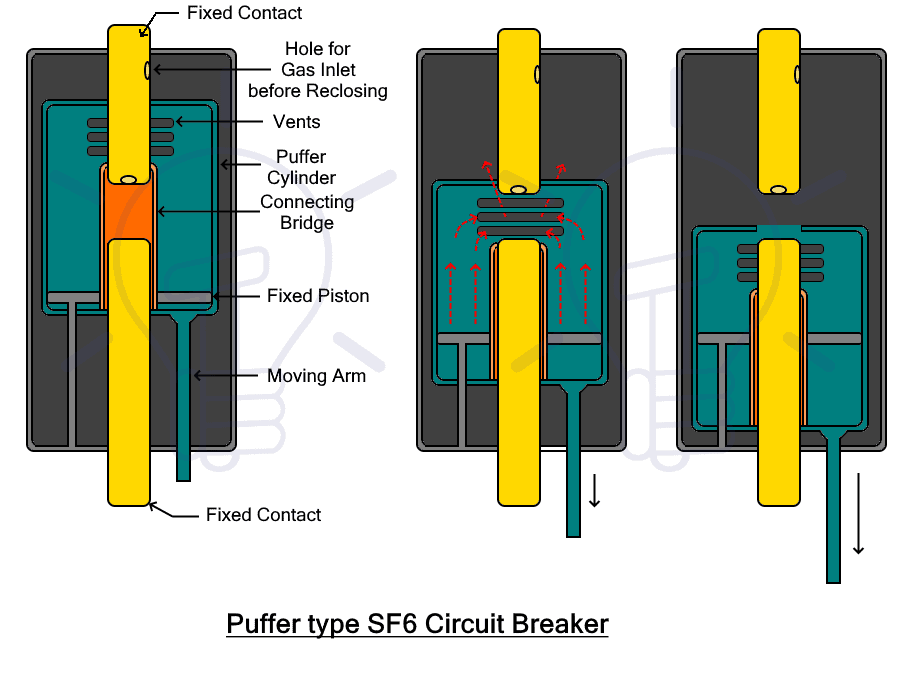

Single Pressure Puffer Type

The puffer-type SF6 circuit breaker mainly includes the puffer cylinder. A puffer cylinder is a movable hollow cylinder that acts as a bridge between the two fixed contacts. It slides upward and downward axially along the contacts to make and break the contact between the two fixed contacts.

Construction

There are two fixed contacts having a small gap between them. A puffer cylinder is placed on top of it. The cylinder is filled with SF6 gas. There is a stationary piston inside the cylinder. When the cylinder moves its volume varies due to the fixed piston. The piston also pushes on the gas increasing its pressure while the pressure is also increased by utilizing the arc energy.

There are vents inside the cylinder and fixed contacts for in and out of the gas. The vents inside the cylinder are blocked by the fixed contact which opens when the cylinder moves downward. The hole inside the fixed contact is used for the inlet of gas when the cylinder goes into the closed position.

The cylinder can move upward and downward by using the moving arm.

Working

Under normal conditions, the puffer cylinder is in a closed position where the connecting bridge connects between the two fixed contacts. The cylinder is filled with SF6 gas. Since the vents are closed by the fixed contact, the SF6 gas remains inside the cylinder.

When a fault condition occurs, the cylinder moves downward to break the connection between the fixed contacts. The medium ionizes and an arc is generated between the contacts.

Due to downward movement and the stationary piston, the volume inside the cylinder decreases which compresses the SF6 gas inside. There are vents inside the cylinder that are previously blocked by the upper fixed contact.

The vents open up when the cylinder moves further down. The compressed SF6 gas moves out at high speed through the vents. The flow of the SF6 gas quenches the arc.

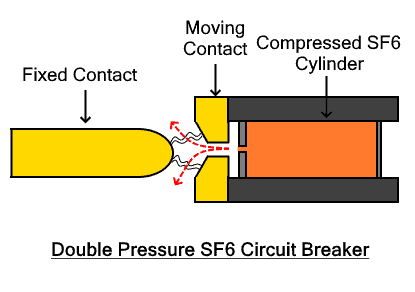

Double Pressure Puffer Type

Such type of SF6 circuit breaker uses compressed SF6 gas in a cylinder to quench the arc. Such CB are obsolete and not used anymore.

Construction

Such SF6 circuit breaker has a fixed contact and moving contact. The moving contact is hollow from inside having a cylinder that stores compressed SF6 gas. The tip of the moving contact is designed in such a way to form a nozzle that increases the speed of the gas when it passes through it.

The fixed contact is designed in such a way when it is in the closed position, it blocks the flow of SF6 gas. When the contacts separate, the path for gas flow is opened which releases a blast of SF6 gas.

It has the same working operation as an air blast circuit breaker except the gas is recombined, compressed and stored in the gas cylinder again. Which makes it very complex and quite expensive gas system is required for operation.

Working

Under normal conditions, the contacts are connected blocking the SF6 gas inside. When a fault occurs, the moving contact separates from the fixed contact and an arc is produced. Due to the movement of contacts, the highly pressurized SF6 gas is released.

The pressure inside the cylinder is higher than the pressure outside, therefore, the gas flows out. The nozzle helps increase the speed of the gas which quenches the arc as discussed earlier.

The released SF6 gas is filtered, recombined, compressed and then stored in the cylinder for further reutilization. The system required to maintain the gas is quite complicated and expensive. Therefore, these circuit breakers are obsolete and not used anymore. Furthermore, due to changes in pressure, the gas temperature falls down very quickly which may liquefy the gas. Therefore, a heater system is also used to prevent the gas from liquification.

- Related Post: Circuit Breaker, Fuse and Protection Symbols

Maintenance of SF6 Circuit Breaker

SF6 circuit breakers are used for high and ultrahigh voltages. Their maintenance is very important for smooth operation. They do not require such frequent maintenance because

- It has an airtight closed circuit gas system

- No carbon deposition is formed that reduces the dielectric strength of the medium.

- No chance of moisture getting inside.

However, there is only one thing that must be maintained that is to check the leakage of SF6 gas. The leakage of SF6 can cause the following issues.

- The leakages of byproduct gases are toxic to the environment (greenhouse gas) and cause respiratory problems.

- SF6 is heavier than air, therefore, it displaces oxygen in confined space causing breathing problems.

- The pressure decrease cause decrease in the dielectric strength of the SF6 gas.

- The SF6 is very expensive.

The leakage can be monitored through the pressure gauge or by using the SF6 detector.

Related Posts:

- Difference Between MCB, MCCB, ELCB and RCD Circuit Breakers

- Difference between Fuse and Circuit Breaker

Advantages & Disadvantages of SF6 Circuit Breakers

Advantages

- Sulphur Hexafluoride or SF6 gas has a superior arc quenching property that is 100 times more effective than air.

- The arcing time is very short.

- SF6 has high dielectric strength due to electronegativity. It increases with an increase in pressure.

- Due to high dielectric strength, the required contact separation is small to prevent arc restriking.

- Due to High dielectric strength, it can interrupt large current.

- It has a compact design. Thus requires small space and cost for installation.

- SF6 gas can handle all kinds of switching phenomena.

- SF6 CB has a closed circuit gas system with no leakage. Therefore, it can be installed in any kind of extreme environment.

- Due to the closed-circuit gas system, there is no problem of moisture.

- The dielectric strength does not reduce because no carbon particles are formed with arcing.

- It does not require an expensive and bulky air compressing system except for the double pressure type which is obsolete.

- The operation of SF6 CB is noiseless.

- SF6 gas is non-toxic in its pure state.

- SF6 gas is non-flammable, thus no chance of fire hazards.

- Since its operation is flawless, it requires less maintenance.

Disadvantages

- The leakage of byproduct gases formed by SF6 gas during arcing are toxic for the environment

- The decomposed SF6 is toxic.

- SF6 is an expensive gas so these circuit breakers are costly.

- Leakage of SF6 from the joints must be continuously monitored.

- It requires special transportation and maintaining the quality of gas.

- The SF6 is heavier than oxygen and can cause difficulty in breathing.

- Recombination and reconditioning of the SF6 gas requires additional equipment.

Application of SF6 Circuit Breakers

SF6 circuit breakers are mainly used for the protection of very high voltage circuits up to 800 kV from fault current. it can safely break and depower a high voltage circuit for any kind of inspection or maintenance.

Each interrupter unit is capable of handling 60 kA in the range of 80 kV. Multiple interrupter units are connected in series to increase their voltage handling capacity according to the system. They are used for the protection of power transmission and distribution systems. They are installed in power generation plants and power grids.

Related Posts:

- HVDC Circuit Breaker – Types, Working and Applications

- Electronic Circuit Breaker – Schematic and Working

- Smart WiFi Circuit Breaker – Construction, Installation and Working

- Tripping Curves of Circuit Breakers – B, C, D, K and Z Trip Curve

- How to Find the Proper Size of Circuit Breaker?

- How to Determine the Number of Circuit Breakers in a Panel Board?

- Why Circuit Breaker Capacity Was Rated in MVA and Now in kA and kV?

- How to Read MCB Nameplate Data printed on it?

- Difference between Fuse and Circuit Breaker

- Difference Between MCB, MCCB, ELCB & RCD

- Difference Between Circuit Breaker and GFCI

- Difference between Circuit Breaker and Isolator / Disconnector

- Difference Between Relay and Circuit Breaker

- Can We Use AC Circuit Breaker for DC Circuit and Vice Versa?

- AFCI: Arc Fault Circuit Interrupter. Types, Working & Applications

- GFCI: Ground Fault Circuit Interrupter. Types, Working & Applications