How to Find the Proper Size of Wire & Cable In Metric & Imperial Systems

How to Determine the Suitable Size of Wire and Cable or Electrical Wiring Installation? Examples in Imperial and Metric Systems Based on NEC, IEC and IEEE.

The following step-by-step guide will show you how to calculate the correct size of cable and wire, or any other conductor, for electrical wiring installations with solved examples in both British or English and SI Systems, i.e., Imperial and Metric Systems, respectively.

Keep in mind that selecting the proper wire size is crucial when sizing a wire for electrical installations. An inappropriate size of wire for larger loads with high current may lead to chaos, resulting in the failure of electrical equipment, hazardous fires, and serious injuries.

This step-by-step guide explains how to calculate the correct wire and cable size for electrical wiring installations. We will use examples in both the British/English and SI systems (Imperial and Metric systems, respectively). The solved examples for wire sizing are based on wire ampacities and current-carrying capacities according to NEC, IEC 60364, 60228, 60898-1, 60947-2 (International Standards), IET Wiring Regulations, BS 7671 (British Standards), and IEEE regulations.

Why is Correct Wire Size Important?

Selecting the correct wire size is crucial when planning and sizing conductors for electrical installations. Using an improper wire size for high-current loads can lead to equipment failure, hazardous fires, and serious injuries.

using correct wire size is crucial in electrical wiring installations for several key reasons:

Safety

Undersized wires can overheat due to excessive current flow, which may lead to electrical fires or equipment damage. Choosing the correct wire size ensures that the wire can handle the expected load without overheating or failing.

Current-Carrying Capacity

Each wire gauge has a specific current-carrying capacity, known as ampacity. Using the proper wire size ensures that the wire can handle the required current without generating excessive heat or voltage drop, ensuring the efficient operation of electrical equipment.

Voltage Drop

Incorrect wire sizing can lead to excessive voltage drop, where electrical power is lost as heat along the wire. This can reduce the efficiency of appliances and lighting, cause motors to underperform, and increase energy consumption. Proper wire sizing minimizes voltage drop and ensures that the correct voltage reaches the end of the circuit.

Compliance with Standards

Electrical codes and standards, such as the NEC, IEC, and BS 7671, specify minimum wire sizes for different applications. Following these regulations ensures that installations are legal, safe, and meet industry standards.

Longevity of the Installation

Correctly sized wires have a longer lifespan because they are less likely to suffer from excessive heat, wear, or mechanical stress. This reduces maintenance costs and the need for early replacements.

Cost Efficiency

While undersized wires pose safety risks, oversizing wires can lead to unnecessary costs. Proper wire sizing strikes a balance between safety, performance, and cost.

Factors Affecting the Wire Size

- Current Carrying Capacity: The amount of current the wire needs to carry (known as ampacity) influences its size, ensuring it can handle the load without overheating.

- Load Current and Breaker Size: The known value of load current in amperes and the rating of circuit breaker.

- Voltage Drop: For longer distances, consideration of voltage drop becomes crucial to maintain the efficiency and proper functioning of the electrical system.

- Ambient Temperature: The environmental temperature affects the wire’s ability to dissipate heat, impacting its current-carrying capacity.

- Insulation Type: Different insulating materials have varying thermal and electrical properties, influencing the overall performance and size requirements.

- Installation Method: The manner in which the wire is installed, whether in conduit, cable trays, or exposed, can affect its ability to dissipate heat and, consequently, its size.

- Conductor Material: Copper and aluminum have different conductivity and temperature characteristics, influencing their suitability for specific applications and, consequently, their sizing.

- Code Guidelines: Adherence to electrical codes and standards is crucial, as they provide specifications and regulations for wire sizing to ensure safety and compliance.

- Type of Load: The nature of the electrical load, whether resistive, inductive, or capacitive, can impact the wire size needed for optimal performance.

- Cable Bundling: When multiple conductors are bundled together, there is a need to derate the ampacity of each conductor, affecting the overall wire size requirements.

- Frequency of Operation: For applications involving alternating current (AC), the frequency of operation can influence the skin effect, affecting the effective resistance and thus impacting wire sizing.

- Types of Cables: It also depends on types of wires and cables for copper and aluminum such as NM-B (Non-Metallic Sheathed Cable) also known as Romex, MC Metal-clad Cables, THHN/THWN, UF-B (Underground Feeder), USE (Underground Service Entrance), SE (Service Entrance):

Voltage Drop in a Cables

All conductors have resistance, which is directly proportional to their length and inversely proportional to their diameter:

R ∝ l/a … [Ohm’s laws of resistance R = ρ (L÷ a)]

As current flows through a conductor, a voltage drop occurs. While it can be neglected for short distances, longer or thinner wires require voltage drop considerations to ensure proper system function.

According to NEC 210.19(A), the maximum recommended voltage drop on a branch circuit is 3% and from the beginning of a feeder to the farthest outlet on a branch circuit should not exceed 5% (215.2(A). For long-distance runs over 50 feet(15.25 meters), consider upgrading to a larger gauge wire to compensate for voltage drop. According to NEC 310-16, for every 100 feet (30.50 meters) of wire length, add 20% ampacity to account for voltage drop.

The IEEE B-23 rule specifies that voltage drop should not exceed 2.5% of the supply voltage.

According to BS 7671 – TABLE 4Ab and IEC60364-5-52, article 525, table G.52.1, the limit of maximum voltage drop for lighting circuits is 3% and 5% of other heating and power usage supplied by public LV distribution system. In case of private LV supply system, the voltage drop for lighting and other HVAC systems is 6% and 8% respectively. If the voltage drop exceeds the limits, larger conductor (cable and wires) must be used to compensate the condition.

According to AS3008, the standard allowable voltage drop from the supply to any point in the circuit should not exceed 5% (AS/NZS 3008). However, an exception is made when a low-voltage substation is installed on the premises and used as a dedicated circuit. In this case, the allowable voltage drop can increase to 7%, as per AS3000.

Example:

If the supply voltage is 230V AC, then the value of allowable voltage drop should be;

Allowable Voltage Drop = 230 (2.5/100) = 5.75V

Similarly, if the supply voltage is 120V AC, the allowable voltage drop should be no more than 3.6V for a separate branch circuit (120V × 3% = 3.6V) and 6V for feeder and branch circuits (120V × 5% = 6V). Refer to NEC Code 210.19(A) and 215.2(A), and Table 310-16, which states that 20% additional ampacity for every 100 feet of distance should be added to counter the voltage drop in the circuit.

In electrical wiring circuits, voltage drops also occur from the distribution board to the various sub-circuits and final sub-circuits. For sub-circuits and final sub-circuits, the allowable voltage drop should be half of the general allowable voltage drop (i.e., 2.75V of 5.5V as calculated above).

Normally, voltage drop tables describe voltage drop in Amperes per meter (A/m), such as the voltage drop in a one-meter cable carrying one Ampere of current.

There are two methods to define voltage drop in a cable, which we will discuss below.

- For SI System (Metric): Voltage drop is defined in terms of per amp per meter.

- For FPS System (Imperial): Voltage drop is defined in volts per ampere per 100 feet (30 m) based on circuit run i.e. distance and length of wire.

Finding Voltage Drop in the Cable

To find the voltage drop in a cable for this tutorial, follow the simple steps below:

- First, find the maximum allowable voltage drop from the give tables.

- Next, determine the load current.

- According to the load current, select an appropriate cable (whose current rating is nearest to the calculated load current) from Table 1.

- From Table 1, find the voltage drop per meter or per 100 feet (depending on your preferred system) according to its rated current.

Now, calculate the voltage drop for the actual length of the wiring circuit based on its rated current using the following formulas:

- (Actual length of circuit × voltage drop per meter) / 100 = Voltage drop per meter.

- (Actual length of circuit × voltage drop per 100 feet) / 100 = Voltage drop per 100 feet.

Next, multiply the calculated voltage drop by the load factor, where:

Load factor = Load current / Rated current of the cable (from the table).

It will show the exact value of voltage drop in the cable when load current is flowing through it.

- If the calculated voltage drop is less than the maximum allowable voltage drop (step 1), then the selected cable size is correct.

- If the calculated voltage drop is greater than the maximum allowable voltage drop (step 1), calculate the voltage drop for the next larger cable size. Continue this process until the calculated voltage drop is less than the maximum allowable voltage drop from step 1.

You may use voltage drop calculator or manual methods using different voltage drop formulas to determine voltage drop and wire size. If the calculated voltage drop is less than the maximum allowable drop, the cable size is appropriate. If it is greater, select the next larger cable size.

How to Determine the Correct Size of Cable & Wire for a Given Load?

Below are solved examples demonstrating how to find the proper cable size for a given load.

For a given load, cable size may be determined using various IEC and NEC tables (such Article 310 – NEC Table 310.16. However, it is crucial to keep in mind the role of ambient temperature and voltage drop for distance between main panel and subpanel.

When determining the size of cable for a given load, take into account the following general rules of thumbs.

- For a given load, apart from the known current value, there should be a 20% additional margin as safety factor for continuous load circuits and for future or emergency needs (required by both NEC and IEC/IEEE).

- In the NEC – 310-16, add an additional 20% ampacity to the wire size if the length of the wire exceeds 100 ft (between the main panel and the subpanel).

- In IEC, the voltage drop should be limited to 1.25%, and for the final sub-circuit, the voltage drop should not exceed 2.5% of the supply voltage from the energy meter to the distribution board.

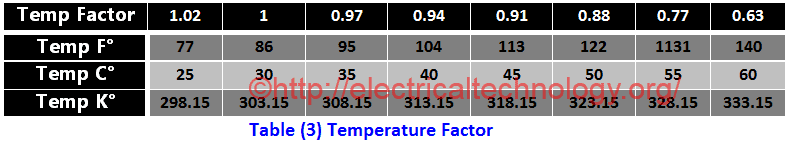

- Consider the change in temperature, which affects the ampacity (current carrying capacity) of the wire. When needed, use the temperature factor (also known as Correction factors or Rating Factors) given in Table 3, Table 6 and related NEC table given at the end of this article).

- Additionally, take the load factor (diversity factor or demand factor (NEC – 220.42 and (220.45)) into consideration when determining the size of the cable.

- When calculating the cable size, consider the ambient temperature and type of wiring system; for example, in an open wiring system, temperature would be low, but in conduit wiring, temperature increases due to the absence of air.

Solved Examples of Proper Cable & Wire Size

The following examples illustrate how to determine the proper size of cables for electrical wiring installations. These examples will make it easy to understand the method of determining the proper cable size for a given load in both single phase ad three phase wiring installations.

Example 1 – (Imperial System Followed by NEC)

What is the correct wire size for a 1,920W load circuit supplied by 120V AC at 60°C (140°F)?

Solution:

First of all, let’s determine the load current in amperes using basic Ohm’s Law that will flow from the 120V breaker to the 1.92kW load.

I (in Amps) = P (in Watts) ÷ V (in Volts)

I = 1,920 W ÷ 120 V

I = 16 Amp

Now, add a safety factor of 1.25 (based on 125% rule also known as continuous load rule), as per NEC 210.20(A) for branch circuits, feeders, and service loads. This code specifies that only 80% of the branch circuit load should be connected to the circuit for the ampacity of the wire for any load.

In other words, the breaker should handle 125% of the rated load current amps. For instance, a 15-ampere breaker should be used for a 12-ampere load point. This way:

I = 16 amp 1.25

or 16 amp 125%

I = 20 Amp.

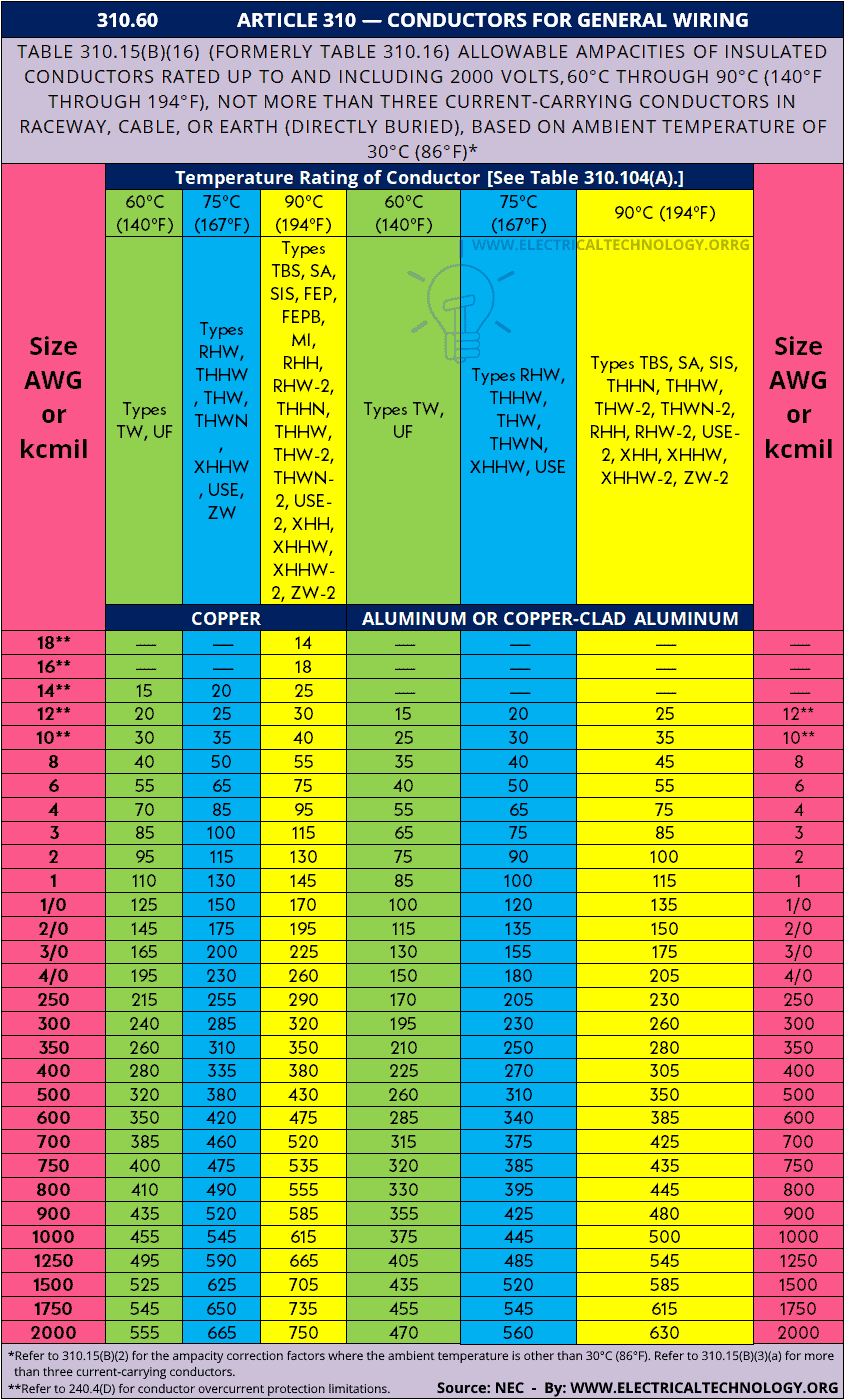

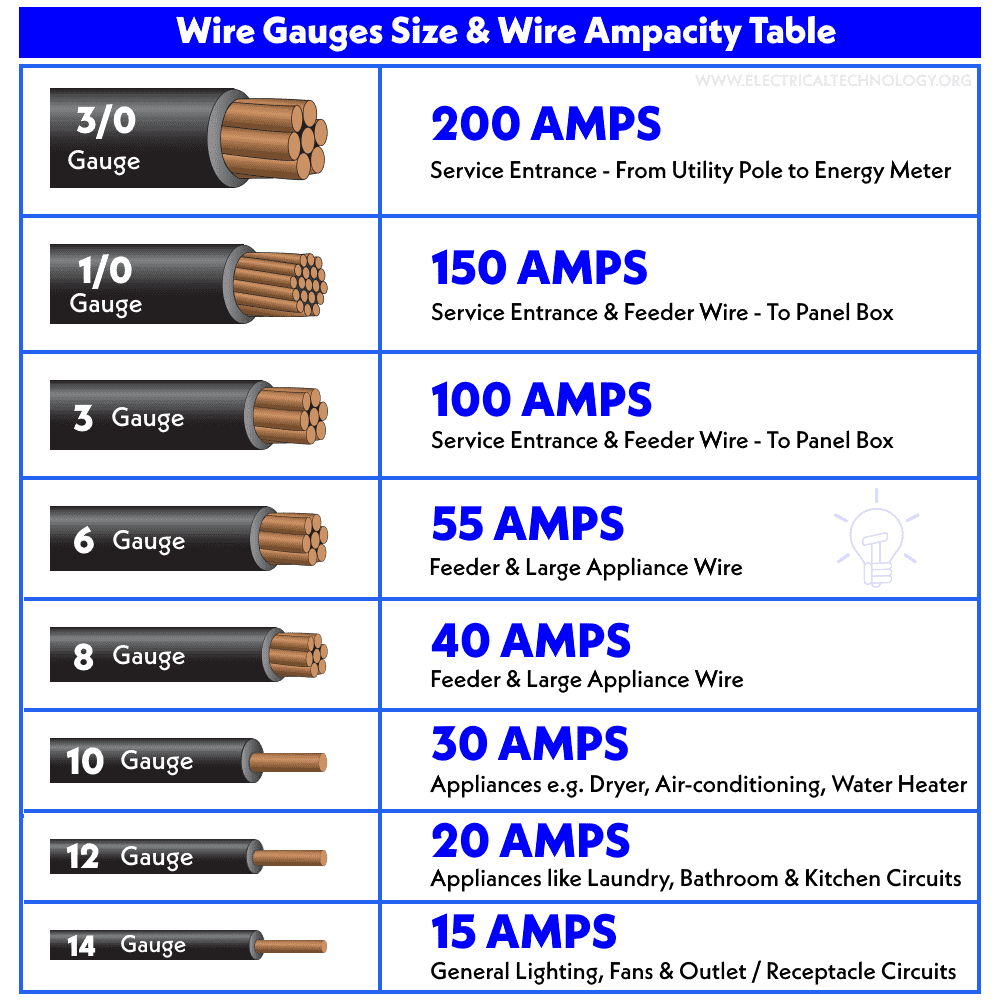

Now, If you see in the AWG wire size chart and NEC Table 310-15B (16) Article 310.60 (given below), the right size for 20 amp circuit is #12 AWG copper or #10 AWG aluminum.

According to 240.4(D), you are permitted to use:

Example 2 – (240V and Distance Involved – NEC)

Find the Proper wire size for 2,400 W load circuit supplied by 240V single phase at a distance of 100 feet?

Solution:

Find the current using the following formula (same as mentioned above)

Current = Power ÷ Voltage

I = 2,400 W ÷ 240 V

I = 10 Amperes

Now, multiply the safety factor of 1.25 (80% of load should be connected of the rated ampacity) to the calculated amperage. The same applies to the breaker size and outlet rating.

As the circuit is 100ft away, add additional 20% ampacity to the calculated value (according to the NEC Code – 310-16) to counter the voltage drop in the circuit.

Total Amps = 12.5A + 2.5A = 15 Amperes.

According to NEC table 310-15B and AWG wire size chart, the suitable wire size for 15 amp circuit is #14 AWG copper at 60°C (140°F) and #12 AWG aluminum.

Notes:

- NEC Table 310.16 with the help of 240.4(A) through (G) which shows the 14 AWG wire size is able to carry 15A at 60°C (140°F) and 20A at 75°C (167°F).

- The determined wire size, breaker rating, and ampacity in the above calculation for North America and Canada comply with the National Electrical Code (NEC) – Sections 210.19(A), 215.2, and 230.42(A) for continuous and non-continuous loads and 110.14(C) for ambient temperature rating.

- This calculation are based on the NEC guidelines. For more details, refer to NEC 210.21, 210, 24, 220.110, 220.14, 220.42, 220.45, 220.53, 220.55, 310-14 and 517.22.

Example 3 – (BS 7671 (British Standards) in Imperial – IEC)

Example: For an electrical wiring installation in a building, where the total load is 5kW and the total length of cable from the energy meter to the sub-circuit distribution board is 35 feet, with a supply voltage of 230V and a temperature of 40°C (104°F), find the most suitable size of cable if wiring is installed in conduits.

Solution:

- Total Load = 5kW = 5 1,000W = 4,500W

- 20% additional load = 5,000 (20/100) = 1,000W

- Total Load = 5000W + 1,000W = 5,400W

- Total Current = I = P ÷ V = 6,000W /230V = 26.08A

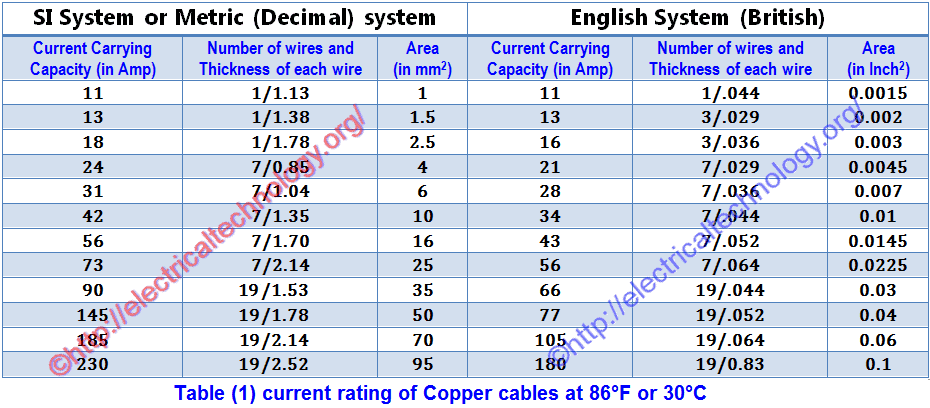

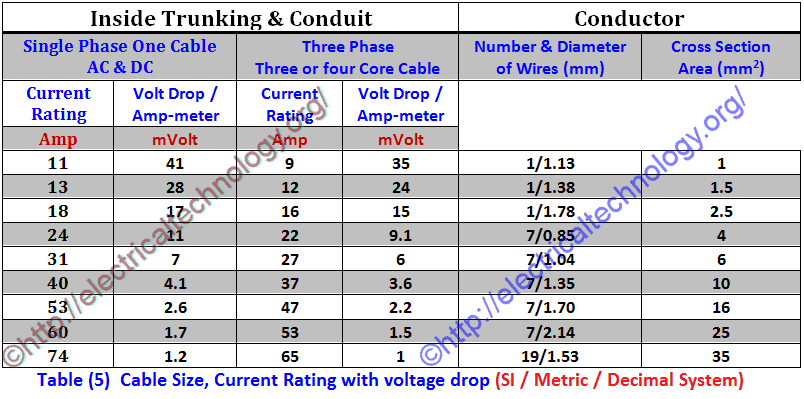

Now select the size of cable for load current of 26.08A (from Table 1 on the right side) which is 7/0.036″ (28 Amperes). It means we can use 7/0.036″ (4 mm2) cable according to table 1.

Now, check the selected (7/0.036″) cable with the temperature factor in Table 3. The temperature factor is 0.94 (from Table 3) at 40°C (104°F), and the current carrying capacity of (7/0.036″) is 28A. Therefore, the current carrying capacity of this cable at 40°C (104°F) would be:

Current rating for 40°C (104°F) = 28 0.94 = 26.32 Amp.

Since the calculated value (26.32 Amp) at 40°C (104°F) is less than the current carrying capacity of the (7/0.036″) cable, which is 28A, this size of cable 4 mm2 (7/0.036″) is also suitable with respect to temperature.

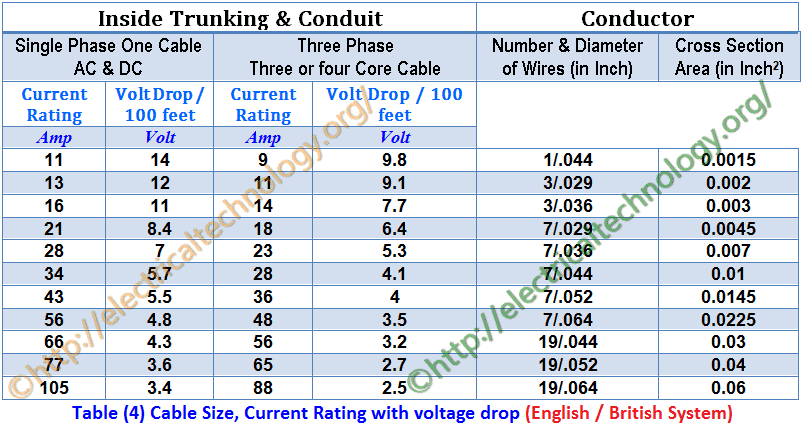

Now find the voltage drop for 100 feet for this (7/0.036″) cable from Table 4 which is 7V, But in our case, the length of cable is 35 feet. Therefore, the voltage drop for 35 feet cable would be;

Voltage Drop = Vd L

Actual Voltage drop for 35 feet = (7V 35/100) (26.08A/28A) = 2.28V

And Allowable voltage drop = 3% 230V = 6.9V

Here, the actual voltage drop (2.28V) is less than the maximum allowable voltage drop of 6.9V. Therefore, the most appropriate and suitable cable size for that given load in the electrical wiring installation is (7/0.036″) which is equal to 4 mm2.

Example 4 – (BS 7671 (British Standards ) in Metric – 18th Ed.)

If the single-phase supply voltage is 230V AC, how do you calculate the circuit current and cable size for each sub-circuit and the main circuit for the following load to be connected in a residential building?

Sub-Circuit 1

- 2 lamps each o 800W and

- 3 fans each of 80W

- 4 TV each of 120W

Sub-Circuit 2

- 6 Lamps each of 80W and

- 5 sockets each of 100W

- 4 lamps each of 800W

Solution:

Total Load of Sub-Circuit 1

= (2 800W) + (3 80W) + (4 120W)

= 1,600W + 240W + 480W = 2,320W

Current for Sub-Circuit 1 = I = P/V = 2,320W/230V = 10A

Total Load of Sub-Circuit 2

= (4 80W) + (5 100W) + (6 500W)

= 320W + 500W + 3,000W= 3,820W

Current for Sub-Circuit 2 = I = P/V = 3,820W/230V = 16.6A

Therefore, Cable suggested for sub circuit 1 having 10A = 1 mm2 (13.5 Amp – Table 6 or Table 5) equivalent to 1/044″ or 3/.029″ (11A and 13 Amp respectively – Table – 4 ).

Cable suggested for Sub-Circuit 2 having 16.6A = 1.5 mm2 (17.5 Amp – Table 6) equivalent to 3/036″ or 7/.029″ (16A and 21 Amp respectively – Table – 4 ).

Total Current drawn by both Sub-Circuits = 10A + 16.6A = 26.6 A

Therefore, cable suggested for Main-Circuit having 26.6A = 4 mm2 (32 Amp – Table 6) equivalent 7/.044″ ( 34 Amp – Table – 4 ).

Example 5 – (IEC 60364 in Metric System – IEC)

Example: What XLPE or EPR size of cable suits for given situation?

- Load = 4.5kW

- Volts = 230V AC – Single Phase

- Length of Circuit = 20 meter

- Temperature = 35°C (95°F)

Solution:

Load = 4.5kW = 4,500 W

Voltage = 230V

Current = I = P/V = 4.500W / 230V = 19.56A

Total Load Current = 19.56A

Now select the size of cable for load current of 19.56A (from Table 6) which is 2.5mm2 (having current capacity of 24 Amperes). Hence, we are allowed to use 2.5mm2 XLPE or EPR cable according to the table 6.

Now check the selected (2.5mm2) conductor with Correction factors or Rating Factors (Ca) for Ambient temperatures in Table 6. As the rating factor or correction factor is 0.96 (in table 6) at 35°C (95°F) for XLPE or EPR cable and current carrying capacity of (2.5mm2) is 24A, therefore, current carrying capacity of this cable at 40°C (104°F) would be;

Current rating for 35°C (95°F) = 24 0.96 = 23.04 Amp.

Since the calculated current (23.04A) at 35°C (95°F) is less than the current-carrying capacity of the 2.5mm² cable, which is 24 A, this cable size is suitable for the temperature conditions

Now find the voltage drop for per ampere meter for (2.5mm²) cable from (Table 8) which is 19mV, But in our case, the length of cable is 35 meter. Therefore, the voltage drop for 20 meter cable would be:

Actual Voltage drop for 35 meters =

= Vd I L

= 19 23.04A /1000) = 8.75V

And 5% Allowable voltage drop = (5 230V)/100 = 11.5V

Here the actual Voltage drop (8.75V) is less than that of maximum allowable voltage drop of 11.7V. Therefore, this is the correct size of cable conductor for that given load.

Example 6 – Three Phase Motor – IEC

A 10H.P (7.46kW) three phase squirrel cage induction motor of continuous rating using Star-Delta starting is connected through 400V supply by three single core PVC cables run in conduit from 250feet (76.2m) away from multi-way distribution fuse board. Its full load current is 19A. Average summer temperature in Electrical installation wiring is 35°C (95°F). Calculate the size of the cable for the induction motor?

Solution:

- Motor load = 10H.P = 10 746 = 7460W *(1H.P = 746W)

- Supply Voltage = 400V (3-Phase)

- Length of cable = 250feet (76.2m)

- Motor full load Current = 19A

- Temperature factor for 35°C (95°F) = 0.97 (From Table 3)

Now select the size of cable for full load motor current of 19A (from Table 5) which is 2.5mm2 (21A). *(Remember that this is a 3-phase system i.e. 3-core cable) and the voltage drop is 13.2V per km (Table 8). It means, we can use 2.5mm2 cable according Table (6).

Now check the selected (2.5mm2) cable with correction factor or rating factor in table (7), so the temperature factor is 0.94 and 0.96 for PVC an XPLE cables (in table 7) at 35°C (95°F) and current carrying capacity of (2.5mm2) is 21 Amperes for 3-phase, therefore, current carrying capacity of this cable at 40°C (104°F) would be:

Current rating for 35°C (95°F) = 21 0.96 = 20.16 Amp.

Since the calculated value (20.16 Amp) at 35°C (95°F) is less than that of current carrying capacity of (2.5mm2) cable which is rated for 21A, therefore this size of cable (2.5mm2) is suitable with the ambient and operating temperature.

Load factor = 19A/23A = 0.826

Now find the voltage drop for 76.2 m (250 feet) for this (2.5mm2) cable from table (8) which is 13.2V for three phase running motor at CosΦ 0.8. But in our case, the length of cable is 250 feet (76.2). Therefore, the voltage drop for this length would be;

Actual Voltage drop for 250 feet (76.2m) = (13.2 19A 76.2/1000) 0.826 = 15.78V

(15.78V÷ 400V) 100 = 3.9 %

This value is less than that authorized (8%) and is satisfactory.

And maximum 8% Allowable voltage drop = (8/100) 400V= 32V

Here the actual Voltage drop (15.78V) is less than that of maximum allowable voltage drop of 32V. Therefore, this is the right wire size for the given 3-phase load.

Wire CSA and Diameter Calculations

Wire Cross Section Area (CSA) Formulas

Wire Cross Sectional Area in kcmil (kilo circular mils)

An = 1000 × dn2 = 0.025 × 92(36-n)/19.5

Where;

- An = cross sectional area of “n” gauge wire size in kcmil.

- kcmil = kilo circular mils.

- n = the number of gauge size.

- d = wire square diameter in in2.

Wire Cross Sectional Area in Square Inches (in2).

An = (π/4)× dn2 = 0.000019635 × 92(36-n)/19.5

Where;

- An = cross sectional area of “n” gauge wire size in square inches (in2).

- n = the number of gauge size.

- d = wire square diameter in in2.

Wire Cross Sectional Area in kcmil (kilo circular mils)

An = (π/4) × dn2 = 0.012668 × 92(36-n)/19.5

Where;

- An = cross sectional area of “n” gauge wire size in square millimeters (mm2)

- n = the number of gauge size.

- d = wire square diameter in mm2.

Wire Diameter Calculation

-

Wire Diameter in Inches Formula

dn = 0.005 × 92(36-n)/39 …. In inches

Where “n” is number of the gauge size and “d” the wire diameter in inches.

-

Wire Diameter in mm (millimeters) Formula

dn = 0.127 × 92(36-n)/39 …. In millimeters (mm).

Where “n” is number of the gauge size and “d” the wire diameter in mm.

Wire Resistance Calculations Formula

(1). Rn = 0.3048 × 109 × ρ / (25.42 × An)

Where;

- R = Resistance of the wire conductors (in Ω/kft).

- n = # of Gauge size.

- ρ = rho = resistivity in (Ω·m).

- An = the cross sectional area of n #gauge in square inches (in2).

Or;

(2). Rn = 109 × ρ/ An

Where;

- R = Resistance of the wire conductors (in Ω/km).

- n = # of Gauge size.

- ρ = rho = resistivity in (Ω·m).

- An = the cross sectional area of n #gauge in square millimeters (mm2).

Tables & Charts for Cable & Wire Sizes

Below are important tables and charts for current-carrying capacity, voltage drop, correction/rating factors, temperature ratings, etc. Using these tables are useful to determine the proper cable size for electrical wiring installations in both single-phase and three-phase supply systems.

BS 7671 – IET & 60364 – IEC Tables

- Table 1 – Current rating of copper cables in mm2 and Inche2 at 30°C (86°F).

Click image to enlarge

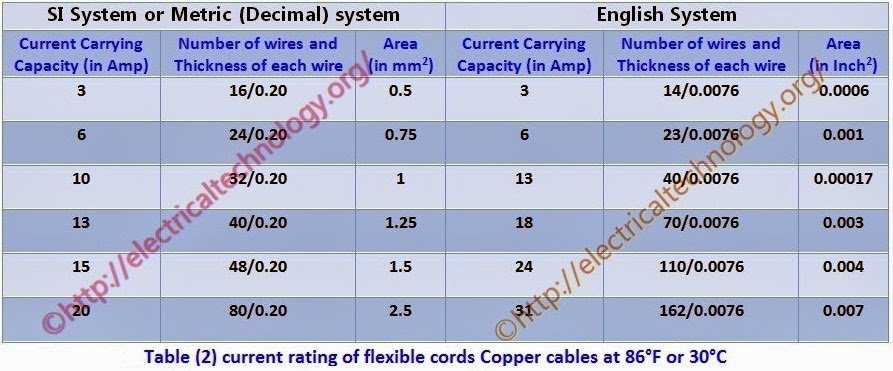

- Table 2 – Current rating of flexible cords – copper cables at 30°C (86°F).

Click image to enlarge

- Table 3 – Temperature factor

Click image to enlarge

- Table 4 – Cable Size in inches with current rating and voltage drop inside trucking and conduit.

Click image to enlarge

- Table 5 – Cable Size in mm2 with current rating and voltage drop inside trucking and conduit.

Click image to enlarge

- Table 6 – Current carrying capacity for 1-Phase and 3-Phase cables based on IEC 60364-5-52 – Table B.52.4 and BS 7671 – Table 4D1A.

- Table 7 – Correction factors or rating factors (Ca) based on IEC 60364-5-52 – Table B.52.14 and BS 7671 – Table 4B1

- Table 8 – Voltage drop values based on IEC 60364-5-52 and BS 7671 – Table 4E1B

- Table 9 – Size of Circuit Breaker and Conductor Selections for Different Domestic Circuits

- Table 10 – IEE Recommended Current Demands and Diversity Factors for Various Loads

- Table 11: Conductor and breaker size selection for domestic and residential application in 230V, single-phase AC circuits for IEC following countries.

- Table 12: Typical current carrying capacity of cables with suggested cable size, current rating in amps and recommended circuit breaker rating in amperes for 230V, single-phase AC circuits for IEC following countries.

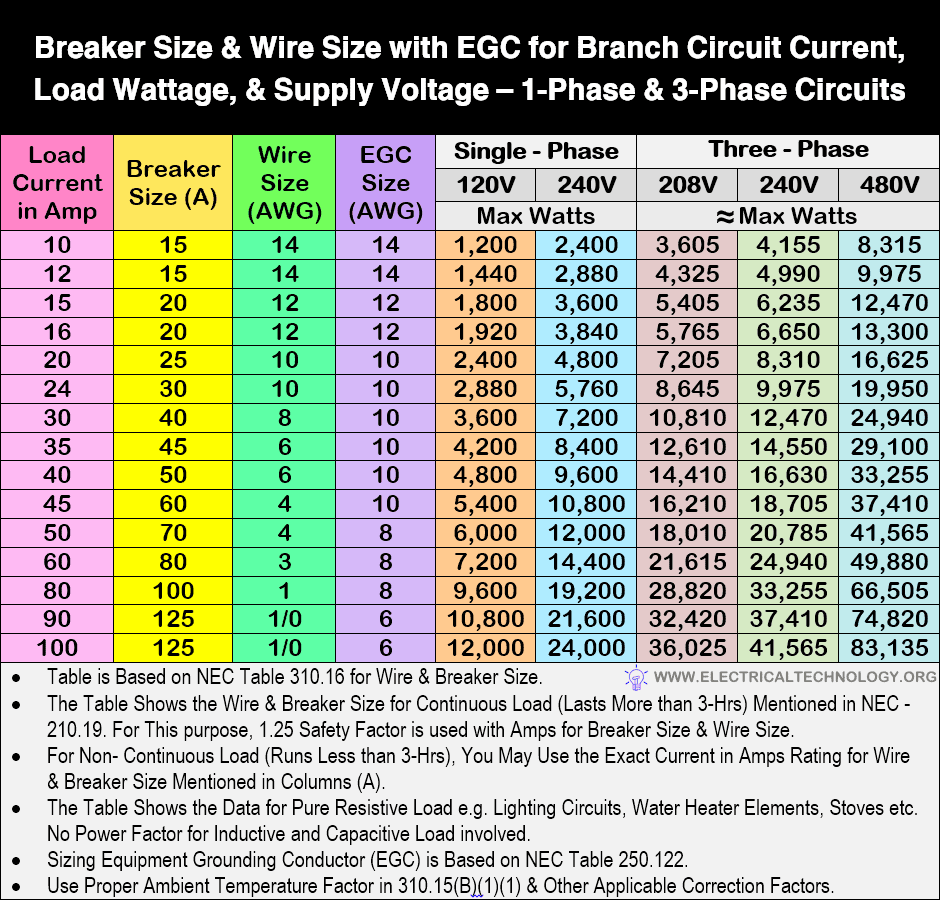

- Table 13: Sizing Breaker, Wire, and Equipment Grounding Conductor (EGC) for Single-Phase and Three-Phase Loads (Based on Load Current and Wattage)

NEC Wire Size Table 310.16 & Chart

NEC (National Electrical Code) Table 310.16 – ARTICLE 310 – Conductors for General Wiring & Allowable Ampacities of Conductors & Wire Sizes based on AWG (American Wire Gauge).

| Table 310.16 ARTICLE 310 — CONDUCTORS FOR GENERAL WIRING | |||||||

| NEC Table 310.16 – Allowable Ampacities of Insulated Conductors Rated Up to and Including 2000 Volts, for Temperatures Ranging from 60°C to 90°C (140°F to 194°F). Applicable to installations with no more than three current-carrying conductors in a raceway, cable, or directly buried in earth, based on an ambient temperature of 30°C (86°F). | |||||||

| Size AWG or kcmil | Temperature Rating of Conductor [See Table 310.4(1).] | Size AWG or kcmil | |||||

| 60°C (140°F) | 75°C (167°F) | 90°C (194°F) | 60°C (140°F) | 75°C (167°F) | 90°C (194°F) | ||

| Types TW, UF | Types RHW, THHW, THW, THWN, XHHW, USE, ZW | Types TBS, SA, SIS, FEP, FEPB, MI, RHH, RHW-2, THHN, THHW,

THW-2, THWN-2, USE-2, XHH, XHHW, XHHW-2, ZW-2 |

Types TW, UF | Types RHW, THHW, THW, THWN, XHHW, USE | Types TBS, SA, SIS, THHN, THHW,

THW-2, THWN-2, RHH, RHW-2, USE-2, XHH, XHHW, XHHW-2, ZW-2 |

||

| COPPER | ALUMINUM OR COPPER-CLAD ALUMINUM | ||||||

| 18** | — | — | 14 | — | — | — | — |

| 16** | — | — | 18 | — | — | — | — |

| 14** | 15 | 20 | 25 | — | — | — | — |

| 12** | 20 | 25 | 30 | 15 | 20 | 25 | 12** |

| 10** | 30 | 35 | 40 | 25 | 30 | 35 | 10** |

| 8 | 40 | 50 | 55 | 35 | 40 | 45 | 8 |

| 6 | 55 | 65 | 75 | 40 | 50 | 55 | 6 |

| 4 | 70 | 85 | 95 | 55 | 65 | 75 | 4 |

| 3 | 85 | 100 | 115 | 65 | 75 | 85 | 3 |

| 2 | 95 | 115 | 130 | 75 | 90 | 100 | 2 |

| 1 | 110 | 130 | 145 | 85 | 100 | 115 | 1 |

| 1/0 | 125 | 150 | 170 | 100 | 120 | 135 | 1/0 |

| 2/0 | 145 | 175 | 195 | 115 | 135 | 150 | 2/0 |

| 3/0 | 165 | 200 | 225 | 130 | 155 | 175 | 3/0 |

| 4/0 | 195 | 230 | 260 | 150 | 180 | 205 | 4/0 |

| 250 | 215 | 255 | 290 | 170 | 205 | 230 | 250 |

| 300 | 240 | 285 | 320 | 195 | 230 | 260 | 300 |

| 350 | 260 | 310 | 350 | 210 | 250 | 280 | 350 |

| 400 | 280 | 335 | 380 | 225 | 270 | 305 | 400 |

| 500 | 320 | 380 | 430 | 260 | 310 | 350 | 500 |

| 600 | 350 | 420 | 475 | 285 | 340 | 385 | 600 |

| 700 | 385 | 460 | 520 | 315 | 375 | 425 | 700 |

| 750 | 400 | 475 | 535 | 320 | 385 | 435 | 750 |

| 800 | 410 | 490 | 555 | 330 | 395 | 445 | 800 |

| 900 | 435 | 520 | 585 | 355 | 425 | 480 | 900 |

| 1000 | 455 | 545 | 615 | 375 | 445 | 500 | 1000 |

| 1250 | 495 | 590 | 665 | 405 | 485 | 545 | 1250 |

| 1500 | 525 | 625 | 705 | 435 | 520 | 585 | 1500 |

| 1750 | 545 | 650 | 735 | 455 | 545 | 615 | 1750 |

| 2000 | 555 | 665 | 750 | 470 | 560 | 630 | 2000 |

|

|||||||

Here is the NEC table as a chart (image format to downloads as a reference)

Click image or open in a new tab to enlarge

Below is the general table based on NEC – 2020 with wire applications, rated ampacity and AWG wire size for given and specific uses.

| Wire Applications | Rated Ampacity | Wire Gauge – AWG |

| Low-voltage lighting circuits | 10 amps | #18 |

| Light duty Extension cords | 13 amps | #16 |

| General lighting circuits, lamps and fixtures | 15 amps | #14 |

| Kitchen, bathroom, and outdoor outlets and receptacles | 20 amps | #12 |

| Electric water heaters, Electric ranges, stove, ovens, cooktops, dryers, air conditioners, | 30 amps | #10 |

| Heavy duty Cooktops and ranges, EV Charging | 40-50 amps | #6 |

| Commercial Electric furnaces, large electric heaters | 60 amps | #4 |

Resources:

Wire Sizes for Standard Breakers, Outlet and Branch Circuits

- Wire Size for 15A Breaker and Outlet

- Wire Size for 20A Breaker and Outlet

- Wire Size for 25A Breaker and Load

- Wire Size for a 30A Breaker and Outlet

- Wire Size for a 35A Breaker and Load

- Wire Size for a 40A Breaker and Load

- Wire Size for 45A Breaker and Load

- Wire Size for 50A Breaker and Outlet

- Wire Size for 55A Breaker and Load

- Wire Size for 60A Breaker and Outlet

- Wire Size for 70A Breaker and Load

- Wire Size for 80A Breaker and Load

- Wire Size for 90A Breaker and Load

- Wire Size for 100A Breaker and Load

Sizing Wires for for General Wiring Installations

- Right Wire Size for100A Service Entrance and Load in AWG for 120V/240V Panel

- What is the Right Wire Size for a 4.8kW, 240V Range: #10 or #12?

- How to Find the Proper Size of Circuit Breaker?

- How to Size a Breaker and Wires in AWG with EGC for Load?

- How to Size a Load Center, Panelboards and Distribution Board?

- How to Size Branch Circuit Conductors with Protection?

- How to Size Feeder Conductors with Overcurrent Protection

- How to Size Service-Entrance Conductors and Feeder Cables?

- How to Size Equipment Grounding Conductor (EGC)?

- How to Size Grounding Electrode Conductor (GEC)?

- How to Size Motor Starter & Contactor – NEMA & NEC

- How to Size Motor Branch Circuit Conductors and Cables

- How to Determine the Number of Circuit Breakers in a Panelboard?

- How to Find Voltage & Ampere Rating of Switch, Plug, Outlet & Receptacle

- How to Determine the Right Size Capacity of a Subpanel?

- How to Size and Find the Numbers of Ceiling Fan in a Room?

- How to Size a Generator? Portable, Backup & Standby for Home & Commercial Applications

- How to Determine the Number of Lighting Branch Circuits?

- How to Determine the Number of Branch Circuits? – 3 Ways

- How to Size a Single Phase and Three Phase Transformer in kVA?

- How to Determine the Suitable Size of Inverter for Home Appliances?

- How to Calculate the Right Size of Solar Charge Controller?

- How to Calculate the Right Size Battery for PV System?

- How to Calculate the Number of Panels for a Load without Battery Backup?

- How to Size Panels, Batteries, Charge Controller and Inverter for PV System in Home

- How to Calculate the Number of Fluorescent Lamps in a Final Sub Circuit?

- How to Calculate the Number of Incandescent Lamps in a Final Sub Circuit?

- How to Calculate the Battery Charging Time & Battery Charging Current ?

- How to Calculate the Floor Area For General Lighting?

- How to Find the Number of Lights on a Single Circuit Breaker?

- How to Find the Number of Outlets on a Single Circuit Breaker?

- How to Size the Earth Conductor, Earthing Lead & Earth Electrodes?

- How to calculate the Cable size for LT & HT Motors?

- How To Locate Faults In Cables? Cable Faults, Types & Causes

- How To Calculate Your Electricity Bill?

Tools:

- Electrical Cable & Wire Size Calculator for Copper & Aluminum

- Wire & Cable Size in AWG Calculator for 1 and 3-Phase Load

- American Wire Gauge “AWG” Chart – Wire Size & Ampacity Table

- American Wire Gauge (AWG) Calculator – AWG Size Chart & Table

- Standard Wire Gauge “SWG” Calculator – SWG Size Chart & Table

- AWG/SWG to mm/mm2, inch/inch2 & kcmil Calculator & Conversion

General Wiring Installations:

- How to Wire 120V & 240V Main Panel? Breaker Box Installation

- How to Wire a Subpanel? Main Lug Installation for 120V/240V

- How to Wire Single-Phase, 230V Consumer Unit with RCD?

- How to Wire a Garage Consumer Unit?

- How to Connect a Portable Generator to the Home Supply – 4 Methods

- How to Connect Automatic UPS / Inverter to the Home Supply System?

- How to Wire an Outlet Receptacle? Socket Outlet Wiring Diagrams

- How To: Electrical & Electronics Tutorials

- Basic Electrical Wiring Installation Tutorials

Thanks Sir,<br /><br />It Gives me all the answers for my question.<br /><br />Thanks Once Again.

Welcome Dear….and Thanks 4 appreciation…

For 10kv how much sqmm ug cable can put

4mm

Cable size cannot said with voltage alone. You have to tell the POWER in KVA OR KW of the load.ALSO THE CORCUIT IS 3 PHASE OR 3 PHASE IS TO BE CLEAR..

Thank you so much. Please don’t stop your work. Great.

Ya I need assistance

Sir

can you help me how to Know the cable size and suitable MCCB rating(example i have 120sqmm x4 core aluminium and 100MCCB is suitable for the above size cable if is not suitable what are possible problem may occureed)

Sir I could not get this "Number of wires & Thikness of each wires" (7 / 0.0229)……….. (70 / 0.0076)<br />Kindly give me answer.<br />

Dear @<br /> 7/0.029 means 7 numbers of wires ( Conductors in a cable) and diameter of each conductor is 0.029" inches.

I think it is: 7 wire strands, each with a 0.029 inch diameter, in a single conductor cable. Is this correct?

Dear sir.,<br />great valuable explanation . i am realy searching this stuff from past 3 years. not i got it just sake of ur study material.

Seems like I am doing exam's numerical, but thanks so much for this post. With high quality cable if you do not know how much the length should it be, then the resistance will be more. And these tables for calculating the Voltage drop really helped a lot

Thanks for Appreciation

Located in Tianchang city, Anhui province, Tianchang Zhengjie Wire Drawing Die Factory is a professional manufacturer of diamond wire drawing dies in China. <a href="http://www.philatron.com/wire-cable-manufacturer/" rel="nofollow">SBR cable</a><br />

sir, can you tell me how to fish a wire through a conduit pipe..

I have a 130 watts panel charging a 120ah battery,and 500 watts inverter.I have connected 65watts TV,decoder,4 15watts lights and 100watts laptop.Looking at the load am I doing the right thing.

<a href="www.https://www.electricaltechnology.org/2013/05/a-complete-note-on-solar-panel.html" rel="nofollow"> A Complete note on Solar panel Installation </a>

Great Work Boss.

Thanks for appreciation

Dear sir,

On above discussion, selection of cable size you are considered voltage drop should not be less than (+ or – 2.5%) of our supply voltage, But according to electricity distributor allowable voltage fluctuation is (+ or – 5%).

please clear my that confusion.

Thanks in advance

Sir,, Plz also explain in new assignments <br />1.how we calculate Breaker Size and its nature? as MCB, MCCB, ACB, VCB <br />2. Calculation of BusBar size w.r.t load ?<br />Thanx

Thanks for Positive feedback,,, Wait for the upcoming posts..

Thank you v much for this useful information…….. Stay blessed.

Welcome Dear, and bundle of thanks for best wishes..

Great Job,thanks a lot for the post.

Thanks for Appreciation

the cable the tech's glove is on has pulled down so much that it is in contact in two places; the upper right meter contact, and the cable guide to the right. <a href="http://500mcmcable.com/" rel="nofollow">750 mcm cable</a><br />

make a thread where show how to do home conduit wiring n all<br />btw grt work

This blog is very informative and I would like to see some more blogs on this topic.<br /><a href="http://www.kowelec.com.au/about-us/" rel="nofollow">Experienced Industrial Electricians At Kowelec Bendigo</a>

gud job you gave the information about copper cables only..wat abt Alluminium armoured cables<br />

than you so much for this useful link

Great site. Wondering the source of tables, is it from any standards? ie. IEC, NEC, etc.<br />Thanks.

sir plz mention the standard according to which the tables have been made.<br /><br />

i want selection of flexible cable standard chart with electric load

If you look carefully at the calculations there are some basic mistake which would effect the final result. ie 2 TV's @ 150w ea. is the shown as 2 x 120w. Other mistake include the lenght calculated which starts at 250 feet then goes to 35 feet and then back to 250 feet.

These are just Examples…. You have to find the suitable size of cable for wiring according to your specification and load requirements… Any way thanks for correction.

sir plz mention the standard according to which the tables have been made.

Thanks for Positive and important Questions.<br />lets try to answer<br /><br />(1)<br />In clear words (for your first Question)<br /><br />Temperature factor means that when temperature increases, Cable/Wire or conductor resistance also increase, hence, Cable/Wire or conductor current carrying capacity decreases. For instance; <br />If the current carrying capacity of wire or cable is 28 Ampere

I am not an electrical engineer, but why does a higher temp in table 3 result in lower temp factor (which makes the calculated value less than the current carrying capacity)? For instance in example 1 – take 43 amps in the table times a temp factor of .94 to yield 40.42 amps. The results is always less than initial amps unless you use a lower temp. Therefore, the higher the temp, the lower the

Would you tell me about the IEC standard in Electrical Installation design and the importance of IEC standard. <br />Thanks for your nice post

if increase frequency value r decrease then what will happen?

Dear Sir.

Thank u very much much for deep explanation.

Do we need to consider power factor in the calculation of load current…..

But,when temprature of conductor increases then resistivty decreases.

When temperature increase resistivity increase too

Dear Sir,

I want to know that if we have no table and we do not remember the current caring capacity of conductor than how can we calculate the cable size? We know the total load, Temperature, Area from DB to load. Please guide.

Good day sir,

Great explanation, but the only aspect am confused of is the area of cable determination,i was expecting the sizes of cable in mm sq as against 7/0.036

thanks for the simple and straight forward language for communication. Please how did you arrive at 5800KW in example 2 above.

Thanks for Appreciation… But where is 5800kW in Example 2… It is 5.8kW = 5800W. :)

thankz a lot bro

nice it’s very helpful for me thanks

I have to install 2 hp single phase pump set load carrying 13 to 15 amps. voltage at site is 220 to 230 volts. Length of cable will be 500 mtrs. Can you suggest required cable size in Copper as well as alluminium ?

Reply me on my email

dear sir

i want to find cable size in mm for the load of 600 amp and the main breaker is 1000 amp area is 120 meters supply voltage is 380 v three phase .

Did You check this?

https://www.electricaltechnology.org/2014/12/advance-voltage-drop-calculator-voltage-drop-formula.html

i have a motor 3phases- 227 kw i want to connect it to the soft starter which size of cable i have to use ?

also can i use 3cores instead of one core so the connection it will be inplace of 3cx…. 9 cores

each pahse will atke three cores Q!?

May Allah ( God ) Bless you for your this type of kind effort , it’s very helpful for me and for electrical related engineers

thanks

how to calculate 3 phase 400 v and 600 amp load’s cable size which must have a length of 25 meter

You can find it by using this calculator. You may also use this one.

how we can make selection of cable for our system

Dear sir, You have done a great job. It’s very helpful to me. You may live long.

Amarasiri from SL.

Thanks for your kind words… :)

dear sir,

please tell me relation between your cabe size(total coductor/ Diameter of each) and square mm cable size

eg. 7/085 cable= ……sq.mm

Dear any body feed back regarding cable selection depending load & length of cable 3 phase application

used cable size is 10 mm load 34.6 Amps 460 .3Ph 60 hz motor

Hi,

What size cable do I need to run 325metres from an 80amp transformer on the power pole so I still have 63amps at the end?

Thank you very much for your assistance.

Sorry, forgot to mention it needs to be 3-phase

Are all made computations, in the samples above, AC or DC? Pleas I need answer.

I have responsibility to provide 150kVA genset to one of social concernt where they have 75kVA sound system with 20 nos of 250W Floodlightings. But my duty is to provide them above generator and power cable reaching to their Main DB panel.

Now, advice me which power cable should I go with the suitable size please???

Please, what size of cable can I use to wire an equipment of 3-phase, 4-wire 120KVA, 50Hz with power factor of 0.8?

This 7core configuration doesnt fit with NEC standards I think. We use 4c or 3c as per requirement. I am seeing for the first time like 7C..?

What formula is followed to make the table? I want to know in given load, length of cable which electrical calculation can be done to find out the size of cable?

Current rating for 40°C (104°F) = 28 x 0.94 = 26.32 Amp.

Since the calculated value (26.32 Amp) at 40°C (104°F) is less than that of current carrying capacity of (7/0.036) cable which is 28A, therefore this size of cable (7/0.036) is also suitable with respect to temperature.

I think this para is trying to say that if temperature increases the current carrying capacity or rating would decrease for the same size of cable. So it means that if my load current is less than the calculated rating of the wire then we can use the wire. So it should say “Since the calculated value (26.32 Amp) at 40°C (104°F) is less than that of load current which is 24.5A, therefore this size of cable (7/0.036) is also suitable with respect to temperature.”

This is with reference to example 1. Please correct if i am wrong.

state two factors to be considered in selection of cables sizes for a house wiring

sir, I have a farm for which I want to put 10 numbers of 25 watts CFL bulbs around the perimeter, the perimeter of the farm is around 1 KM. Can you please confirm what type of wire I need to use (gauge, insulation requirements, Copper vs Aluminum), Considering that I will be laying this underground through pipes (which might be exposed to water at times…I need wires that are resistant to moisture and soil interaction). I am planning on using drip pipes which are cheaper and pass the wires through them. Please advise. This will be run on solar power. I will size the solar power unit accordingly.

I want to know about it.

If you have a time or see this comment, Please reply me.

In example 1,

Why are you using that I = P/V?

Total Current = I = P/V = 5400W /220V =24.5A

Actually, It should be which is I = P/( V x PF)

Assume , Power Factor (PF) will be 0.8.

Total Current = I = P/( V x PF) = 5400W /( 220 x 0.8)V =30.68 A

bro I= P/V for DC and I= P/V x PF for AC Power

What is power factor?

You may read about

sir plz mention the standard according to which the tables have been made.

Total load 32 KW 3phase 4wire system (distribute)220 volt 1phase and length 140 Meter .what is cable size use in mm

sir, please provide below information with necessary calculations

for 200/150 HP/Kw 3-phase induction motor

1. cable size from pannel to starter to motor and from HT transformer to LT pannel

2. type of starter to be used

3. Type of pannel to be used

thanks

Can you please tell me which Electrical Code did you use in above calculations?

I have 3phase 10 HP Moto ,16 amps,which size cable is sutiable,iam Diploma EEE,Fresher on maintenance Engineer on on eharama company,plz give me cable size flexible or armed cable.core and mm size plzz give,mee

you are calculating full load current of a 3 phase motor. that doesnot include sq.root of 3.

I Thank You Mr. Khan, for your great effort in helping your visitors with an easy to understand presentation. I must tell you you are the best online teacher and you understood what basics people must know before they would understand the subject matter. I guess you must be a generous human being who is helping others not to fail in life. keep up the effort!

Thanks again!

Thank you so much for appreciation,,,, :)

Honestly i enjoyed the tutorials, its quite interesting for all engineering student both graduates and under graduates… i appreciate the effort of electrical technology for her convenient idea of letting some techs into us. Thanks alot

Many thanks, for your outstanding efforts in educating and assisting all peoples to understand such valuable technical subjects.

Good explaination of calculating the size of the cable.

I got this (V.D of m = mV x I x L) a bit confusing. How is this formula derived? If you apply the values and their units, ypu dont get volts per ampere meter at the end.

Can you justify please.

Thanks for the information about electrical wiring

how to find out 240RM cable , which is actual system

great work

how did you find load factor for the last example ? we have replace the selected cable with new one, why do you choose the same load factor ?

Which questions are asking for industrial electrician in interview please reply

Hazadous Location

thank you very much, it is very useful, I hope you give us more examples of three-phase circuits.

Best regards.

Eng. Abdolgabar Ahmed Mahmood.

Great article about wiring and installation.

Short and brief description thank you.

I want to ask about question number 4

In load factor, at first calculation of cable size(load factor)=19/23=0.82

But, after we change the cable size with higher size, why the load factor use in calculation still 0.82, isn’t that (load factor)=19/28?

Previously, i want to say thank you, this website is very incredible

First, i thank. In eg.1 the load factor is 24.5/ 28. In eg.2 it is change into I and is not 30.2/31 . Why is it. Please reply me if you have time. Pardon me if i wrote faulty because i am not fluency in english. Thank.

sir, my Q is how find / calculate the amps if the conductor size of cable is 32/0.2 mm and v 440

Dear sir

Please answer this

20 HP,415 v,0.8 of,3phase,0.85efficiency,1440 rpm and delta connected induction motor is to be connected to a motor control center by a cable of length 15 m,this cable is running with three other cables,ambient temperature is 45 degree Celsius and fault level is 20 KA,select the size of the cable from below

PVC cable 300mm.value of k/cu 103.value of k/al 68

XLPE cable <300mm.value of k/cu 114.value of k/al 92

It’s really great job to learn online from basic to till all experience fields i would like to have a request for lesson

1. Testing & commission of electrical equipment in substaion

2. CNC machines , types , work principles

3. Site Engineer work in Substaions

4. Single line diagram module and it’s implementation

5. QA or QC work and their Electrical Standards.

It will be very thankful if you can provide these important lessons to us to gain knowledge through your website atleast with video upload to have knowledge in theory as well as in practicle

Hello ….. could you please calculate the 3-phase question using the metric table. The answer I am getting is unrealistic.

Hi Thomas ?

Can you please elaborate more in details ?

Sir,

I requesting to you please, make the blog and video of electrical wiring installation of any flate/home.

And your blogs are so useful for us.

Thanking you.

Having determine my total load requirements after considering all factors

for example say load current is 750A for a 3phase supply

If l want to use single core pvc/ pvc cable

Do l divide the 750A by 3 before chosen the corresponding cable size from the catalog or not

Regards

Bosun

Good way of describing, and nice piece of writing to obtain data about my presentation subject, which i am going

to convey in school.

Tanks you sir

How to connecting RCCB and RCB

Hi!

I use more simple way. I find R of cable R=ρ ×L/A, where

R is the resistance of the conductor in Ohms;

L is the length of the conductor in meters;

ρ is the electrical resistivity (also known as the specific electrical resistance) of a conductor, for cooper ρ=0,018 Ohm · mm²/m;

A is the cross-sectional area, measured in square millimeters.

Then find voltage drop

for L+N voltage system, dU (V)= I×R×2,

for L+L voltage system, dU (V)= I×R,

Where I is a current in wire;

dU(V) is a voltage drop in volt.

And in the end I find dU in %

dU(%)=dU(V)×100/U

where U is a line voltage.

Sorry for my english.

Very good sir.

Thank you for this blog

Please add tutorials about MC, CB, O/L, FUSE, T/F, generators and motors suitable size calculations.

Hi, I am very impress of this blog . It is very much helpful for us as electrical engineer students in our respective areas of interest .

Please , for the information above , I really want a PDF copy of it .

Thanks once more …

Assalam alikum sir

Why power factor is not taken in calculation as it is AC circuit?

I am very impressed of ur blogs. pl post a table of cable & alu conductor current rating of different sizes to b use in ht/ lt lines in state utilities in day today practice.

Could you let me know how is the margin factor for rated current of 3 phase inverter load?

I remember it may be 1.35 times of In due to harmonic wave but for 1.25 times of 3 phase induction motor load.

I also would like to know how is the margin factor for rated current of 3 phase inverter unit to use solar power generation equipped with harmonic filter facility internally.

Thanks for your technical service.

its checks with my calculation by standard. good job